Composite reagent for boiler and preparation method of composite reagent

A compound agent and boiler technology, applied in chemical instruments and methods, degassed water/sewage treatment, special treatment targets, etc., can solve problems such as poor scale and corrosion inhibition effects, eutrophication of water bodies, and environmental protection , to achieve the effect of avoiding excessive phosphorus discharge, avoiding eutrophication, and preventing scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

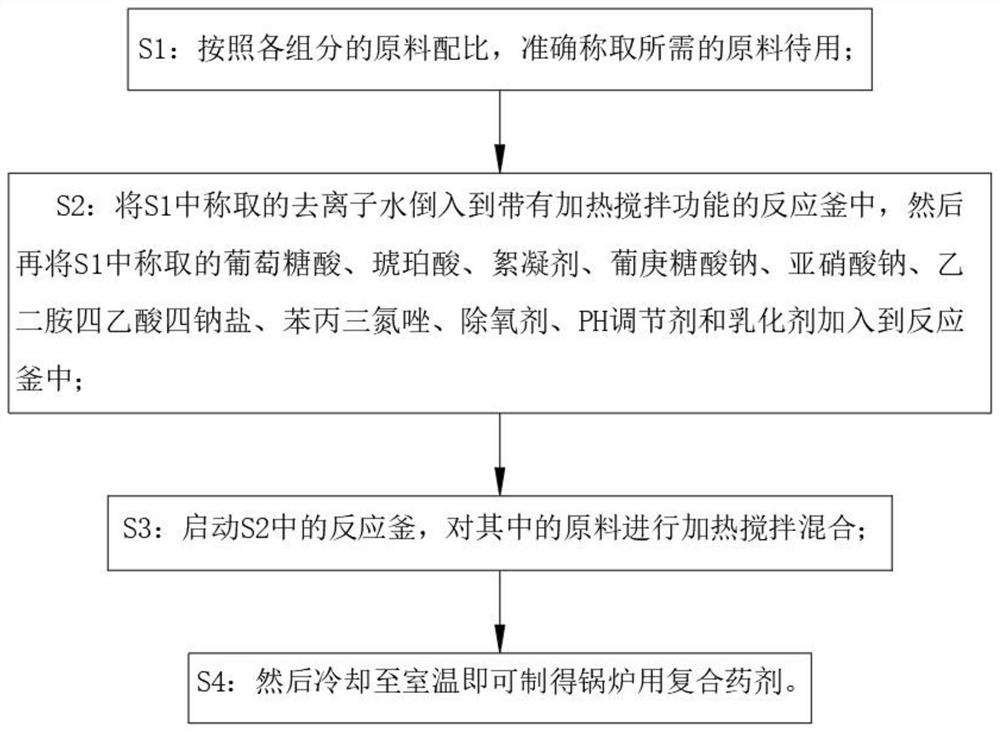

[0024] see figure 1 , the present invention provides the following technical scheme: a boiler composite agent, comprising the following components in parts by mass: 0.5 parts of gluconic acid, 1.5 parts of succinic acid, 0.3 parts of flocculant, 0.7 parts of sodium glucoheptonate, and 0.5 parts of sodium nitrite , 93 parts of deionized water, 0.5 part of tetrasodium edetate, 0.5 part of benzotriazole, 0.5 part of oxygen scavenger, 1 part of pH regulator, and 1 part of emulsifier.

[0025] Specifically, the pH regulator is potassium hydroxide.

[0026] Specifically, the oxygen scavenger is dimethyl ketoxime.

[0027] Specifically, the emulsifier is dimethylol butyric acid.

[0028] Specifically, the flocculant is sodium polyacrylate.

[0029] A preparation method for a composite agent for a boiler, comprising the following steps:

[0030] S1: According to the raw material ratio of each component, accurately weigh the required raw materials for use;

[0031] S2: Pour the de...

Embodiment 2

[0036] see figure 1 , the present invention provides the following technical scheme: a composite agent for boilers, comprising the following components by mass: 1.5 parts of gluconic acid, 1.5 parts of succinic acid, 0.5 parts of flocculant, 0.5 parts of sodium glucoheptonate, and 0.8 parts of sodium nitrite , 89 parts of deionized water, 1.2 parts of tetrasodium ethylenediaminetetraacetic acid, 0.7 parts of benzotriazole, 1.3 parts of oxygen scavenger, 1.5 parts of pH regulator, and 1.5 parts of emulsifier.

[0037] Specifically, the pH regulator is potassium hydroxide.

[0038] Specifically, the oxygen scavenger is dimethyl ketoxime.

[0039] Specifically, the emulsifier is dimethylol butyric acid.

[0040] Specifically, the flocculant is sodium polyacrylate.

[0041] A preparation method for a composite agent for a boiler, comprising the following steps:

[0042] S1: According to the raw material ratio of each component, accurately weigh the required raw materials for u...

Embodiment 3

[0048] see figure 1 , the present invention provides the following technical scheme: a composite agent for boilers, comprising the following components by mass: 2 parts of gluconic acid, 2 parts of succinic acid, 0.8 parts of flocculant, 0.7 parts of sodium glucoheptonate, and 1.5 parts of sodium nitrite , 88 parts of deionized water, 1 part of tetrasodium ethylenediaminetetraacetic acid, 1 part of benzotriazole, 1 part of oxygen scavenger, 1.5 parts of pH regulator, and 0.5 part of emulsifier.

[0049] Specifically, the pH regulator is potassium hydroxide.

[0050] Specifically, the oxygen scavenger is dimethyl ketoxime.

[0051] Specifically, the emulsifier is dimethylol butyric acid.

[0052] Specifically, the flocculant is sodium polyacrylate.

[0053] A preparation method for a composite agent for a boiler, comprising the following steps:

[0054] S1: According to the raw material ratio of each component, accurately weigh the required raw materials for use;

[0055] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com