Corrosion-resistant synchronous belt for glass cleaning robot and preparation method of corrosion-resistant synchronous belt

A glass cleaning robot and synchronous belt technology, applied in the field of synchronous belts, can solve the problems of limited continuous use effect and limited use of synchronous belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

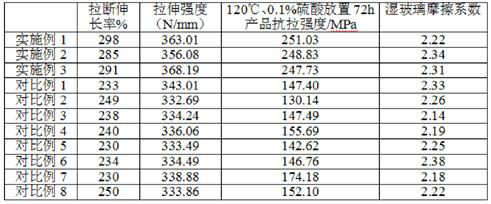

Embodiment 1

[0032] A corrosion-resistant synchronous belt for a glass-wiping robot, prepared from the following raw materials in parts by mass:

[0033] 80 parts of neoprene rubber, 20 parts of styrene-butadiene rubber, 10 parts of fluororubber, 3 parts of chlorosulfonated polyethylene, 5 parts of polyparaphenylene benzobisoxazole fiber net, 0.1 part of benzalkonium ammonium, dibenzyl di 0.05 part of neodymium thiocarbamate, 0.5 part of lanthanum citrate, 1 part of modified mica; the fluororubber is powder with a fineness of 1500 mesh; The lanthanum chloride solution is formed by reacting under nitrogen atmosphere according to the mass ratio of 5:1; the modified mica is composed of ultrafine mica powder, vinyltrimethoxysilane, hydrochloric acid, and stearic acid with a mass ratio of 12:0.1:1:0.3 Prepared.

[0034] The method for preparing a corrosion-resistant synchronous belt for a glass-wiping robot described in this embodiment includes the following steps:

[0035] (1) Solution confi...

Embodiment 2

[0048] A corrosion-resistant synchronous belt for a glass-wiping robot, prepared from the following raw materials in parts by mass:

[0049] 95 parts of chloroprene rubber, 35 parts of styrene-butadiene rubber, 12 parts of fluororubber, 5 parts of chlorosulfonated polyethylene, 8 parts of polyparaphenylene benzobisoxazole fiber net, 0.2 parts of benzalkonium, dibenzyl di 0.06 part of neodymium thiocarbamate, 0.8 part of lanthanum citrate, 1.5 part of modified mica; the fluorine rubber is a powder with a fineness of 2000 mesh; Lanthanum chloride solution is formed by reacting under nitrogen atmosphere according to the mass ratio of 8:1; the modified mica is formed by mica ultrafine powder, vinyltrimethoxysilane, hydrochloric acid, stearic acid with a mass ratio of 15:0.2:1:0.5 Prepared.

[0050] The method for preparing a corrosion-resistant synchronous belt for a glass-wiping robot described in this embodiment includes the following steps:

[0051] (1) Solution configuration...

Embodiment 3

[0064] A corrosion-resistant synchronous belt for a glass-wiping robot, prepared from the following raw materials in parts by mass:

[0065] 87 parts of neoprene rubber, 22 parts of styrene-butadiene rubber, 11 parts of fluororubber, 4 parts of chlorosulfonated polyethylene, 7 parts of polyparaphenylene benzobisoxazole fiber net, 0.2 parts of benzalkonium, dibenzyl di 0.06 part of neodymium thiocarbamate, 0.8 part of lanthanum citrate, 1 part of modified mica; the fluororubber is a powder with a fineness of 2000 mesh; The lanthanum chloride solution is formed by reacting under a nitrogen atmosphere according to a mass ratio of 8:1; the modified mica is composed of ultrafine mica powder, vinyltrimethoxysilane, hydrochloric acid, and stearic acid with a mass ratio of 12:0.2:1:0.5. Prepared.

[0066] The method for preparing a corrosion-resistant synchronous belt for a glass-wiping robot described in this embodiment includes the following steps:

[0067] (1) Solution configurat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com