Nano needle-shaped bismuth phosphate material as well as preparation method and application thereof

A bismuth phosphate and nano-needle technology, applied in phosphates, phosphorus oxyacids, nanotechnology and other directions, can solve the problems of potassium storage capacity loss, insufficient promotion and application, etc., and achieve low equipment requirements, low operating costs, and excellent cycle performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Dissolve 0.5mmol of bismuth nitrate pentahydrate in 50ml of ethylene glycol to form a mixed solution. Subsequently, 0.5 mmol of ammonium dihydrogen phosphate powder was slowly added to the above mixed solution. Stir magnetically at room temperature for 40 minutes, then get a clear solution, then slowly add 1mL of deionized water to the solution, stir slowly for 10 minutes, and get a cloudy solution, then put it into a Teflon liner and place it in an oven at 160°C for 24 hours , to obtain a gray solution, which was centrifuged and washed three times with absolute ethanol and once with deionized water, and then put into a blast drying oven at 120° C. for 8 hours to obtain a gray powder, which is a bismuth phosphate nanomaterial.

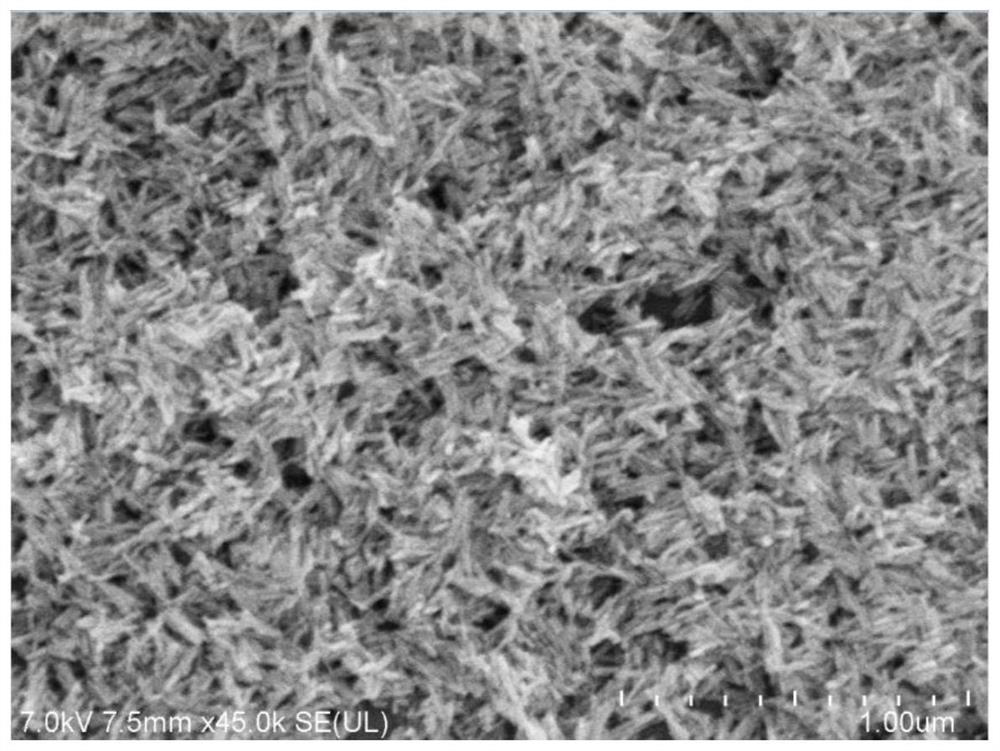

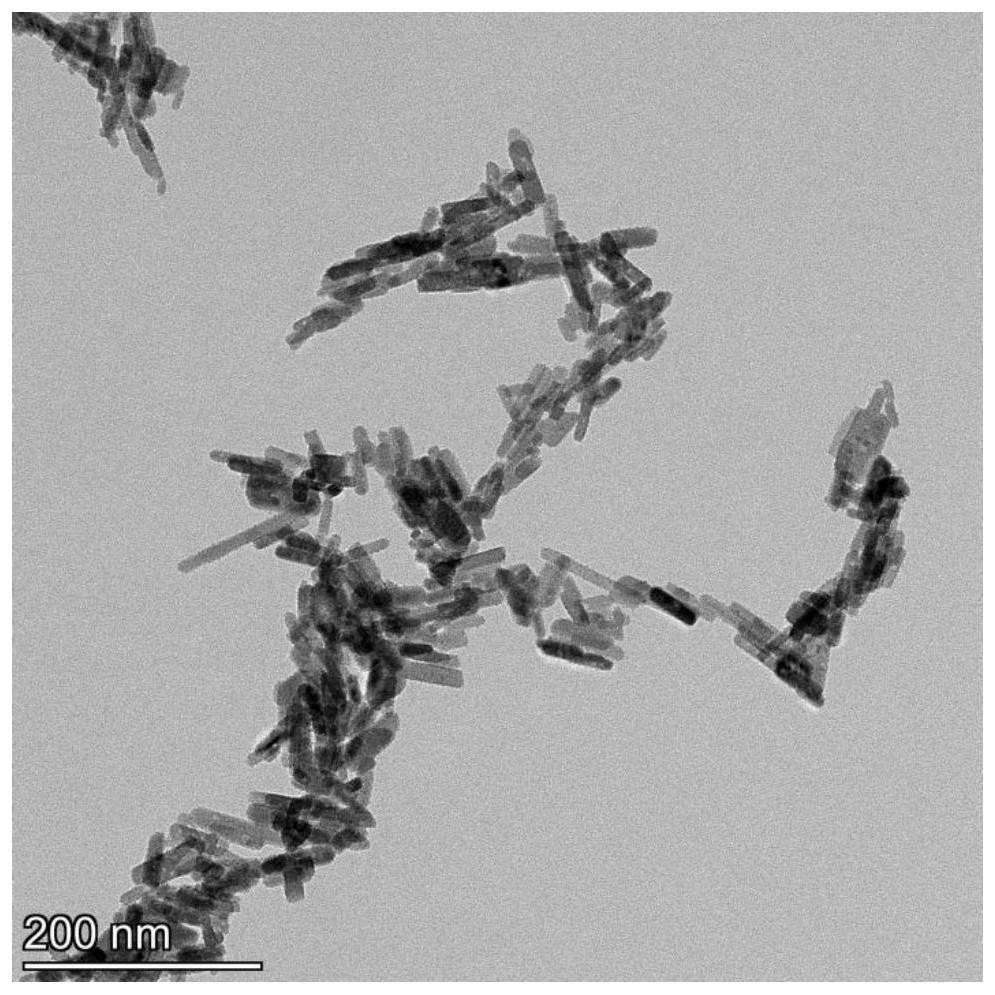

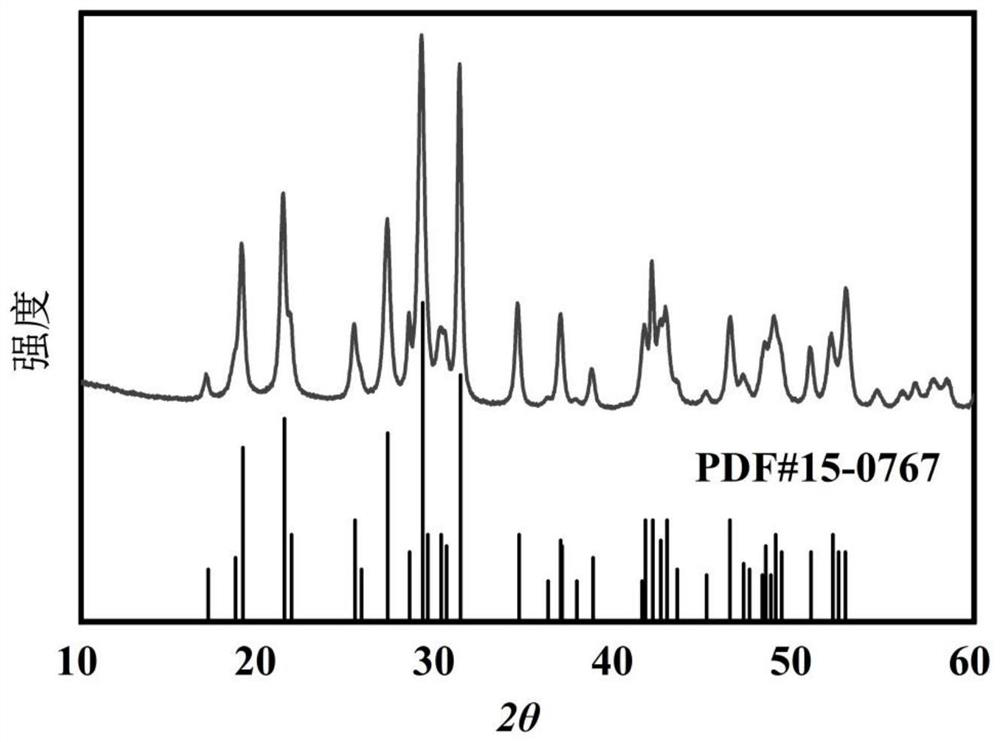

[0037] figure 1 Be the field emission scanning electron micrograph of the obtained bismuth phosphate nanomaterial of embodiment 1; From figure 1 It can be seen that the synthesized bismuth phosphate needle-like nanomaterials are relatively uni...

Embodiment 2

[0039] Dissolve 0.5mmol of bismuth nitrate pentahydrate in 70ml of ethylene glycol to form a mixed solution. Then 0.5 mmol of ammonium dihydrogen phosphate powder was slowly added to the above mixed solution. Stir magnetically at room temperature for 40 minutes, then obtain a clear solution, then slowly add 3 mL of deionized water to the solution, and slowly stir for 2 days to obtain a cloudy solution, then put it into a Teflon liner and place it in an oven at 160°C for 48 hours. Obtain a gray-black solution, centrifuge it, wash it with absolute ethanol for 3 times, then wash it with deionized water once, and finally wash it with absolute ethanol, then put it into a blast drying oven for 8 hours at 120°C to obtain a gray-black powder , which is bismuth phosphate nanomaterial.

[0040] Figure 6 Be the field emission scanning electron micrograph of the obtained bismuth phosphate nanomaterial of embodiment 2; From Figure 6 It can be seen that the prepared bismuth phosphate n...

Embodiment 3

[0042] Dissolve 0.5mmol of bismuth nitrate pentahydrate in 30ml of ethylene glycol to form a mixed solution. Then 0.5 mmol of ammonium dihydrogen phosphate powder was slowly added to the above mixed solution. Stir magnetically at room temperature for 40 minutes, then obtain a clear solution, then slowly add 3 mL of deionized water to the solution, and stir slowly for 10 minutes to obtain a cloudy solution, then put it into a Teflon liner and place it in an oven at 160°C for 12 hours , to obtain a light gray solution, which was centrifuged and washed three times with absolute ethanol, then once with deionized water, and finally washed with absolute ethanol, and then put into a blast drying oven at 120°C for 8 hours to obtain light gray The powder is the bismuth phosphate nanomaterial. Figure 7 It is the field emission scanning electron micrograph of the bismuth phosphate nanomaterial obtained in Example 3. From Figure 7 It can be seen that the prepared bismuth phosphate na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com