Iron-based soft magnetic composite material with mesoporous structure coating layer and preparation method of iron-based soft magnetic composite material

A soft magnetic composite material, mesoporous structure technology, applied in the direction of inorganic material magnetism, inductor/transformer/magnet manufacturing, electrical components, etc. The effect of reducing force, eliminating residual stress, and reducing loss of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

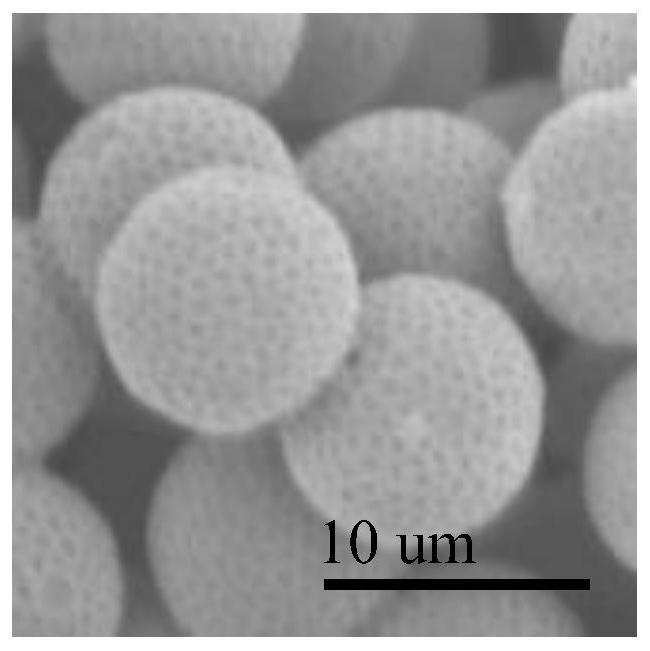

[0032] Step 1. Put ultra-fine spherical pure iron powder with a particle size of 1 μm into acetone solvent, add silane coupling agent to activate the surface of the powder, and put it in a blast drying oven at 50°C for later use;

[0033] Step 2, TiO 2 Hydrogel preparation: measure 3.0g of F127, 5.0g of acetic acid, 7.0g of concentrated hydrochloric acid with a mass fraction of 36wt%, put them into a beaker filled with 60mL of tetrahydrofuran solvent, stir vigorously for 15min, and add 7.0g of tetrabutyl titanate dropwise Add 0.3mL of deionized water to form a yellow-white solution after magnetic stirring for 10min. Move the above solution into a blast drying oven and dry it at 50°C for 24h to form TiO 2 / surfactant complex light yellow hydrogel;

[0034]Step 3. Weigh 2 g of the above-mentioned light yellow gel, put it into a beaker filled with 30 mL of absolute ethanol, stir vigorously for 10 min to form a transparent solution, add 30 mL of glycerin drop by drop and stir con...

Embodiment 2

[0038] Step 1. Put ultra-fine spherical pure iron powder and spherical sendust aluminum powder with a particle size of 10 μm into acetone solvent, add silane coupling agent to activate the surface of the powder, and put it in a blast drying oven for drying at 60°C for later use;

[0039] Step 2, TiO 2 Hydrogel preparation: measure 3.0g of F127, 5.0g of acetic acid, 7.0g of concentrated hydrochloric acid with a mass fraction of 36wt%, put them into a beaker filled with 60mL of tetrahydrofuran solvent, stir vigorously for 15min, and add 9.0g of tetrabutyl titanate dropwise Add 0.5mL of deionized water to form a yellow-white solution after magnetic stirring for 12min. Move the above solution into a blast drying oven and dry it at 55°C for 22h to form TiO 2 / surfactant complex light yellow hydrogel;

[0040] Step 3: Weigh 4 g of the above-mentioned light yellow gel, put it into a beaker filled with 120 mL of absolute ethanol, stir vigorously for 10 min to form a transparent solut...

Embodiment 3

[0044] Step 1. Put the ultra-fine spherical iron-silicon-chromium alloy powder with a particle size of 20 μm into an acetone solvent, add a silane coupling agent to activate the surface of the powder, and put it in a blast drying oven for drying at 70°C for later use;

[0045] Step 2, TiO 2 Hydrogel preparation: measure 3.0g of F127, 5.0g of acetic acid, 7.0g of concentrated hydrochloric acid with a mass fraction of 36wt%, put them into a beaker filled with 60mL of tetrahydrofuran solvent, stir vigorously for 15min, and add 7.0g of tetrabutyl titanate dropwise Add 0.3mL of deionized water to the ester, and after magnetic stirring for 10min, a yellow-white solution is formed. Move the above solution into a blast drying oven, and dry it at 60°C for 20h to form TiO 2 / surfactant complex light yellow hydrogel;

[0046] Step 3. Weigh 2 g of the above-mentioned light yellow gel, put it into a beaker filled with 30 mL of absolute ethanol, stir vigorously for 10 min to form a transpa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com