Organic compound, mixture and composition and application thereof

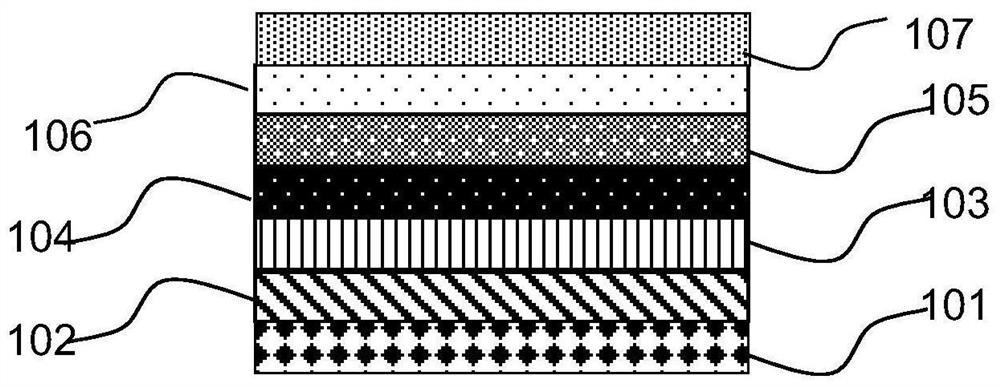

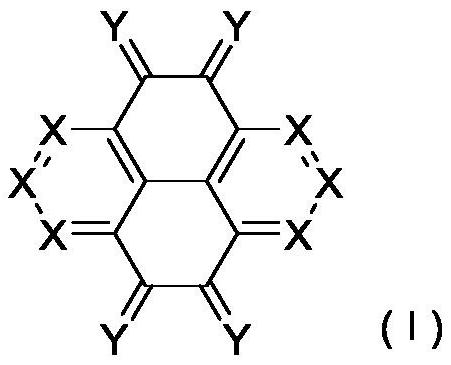

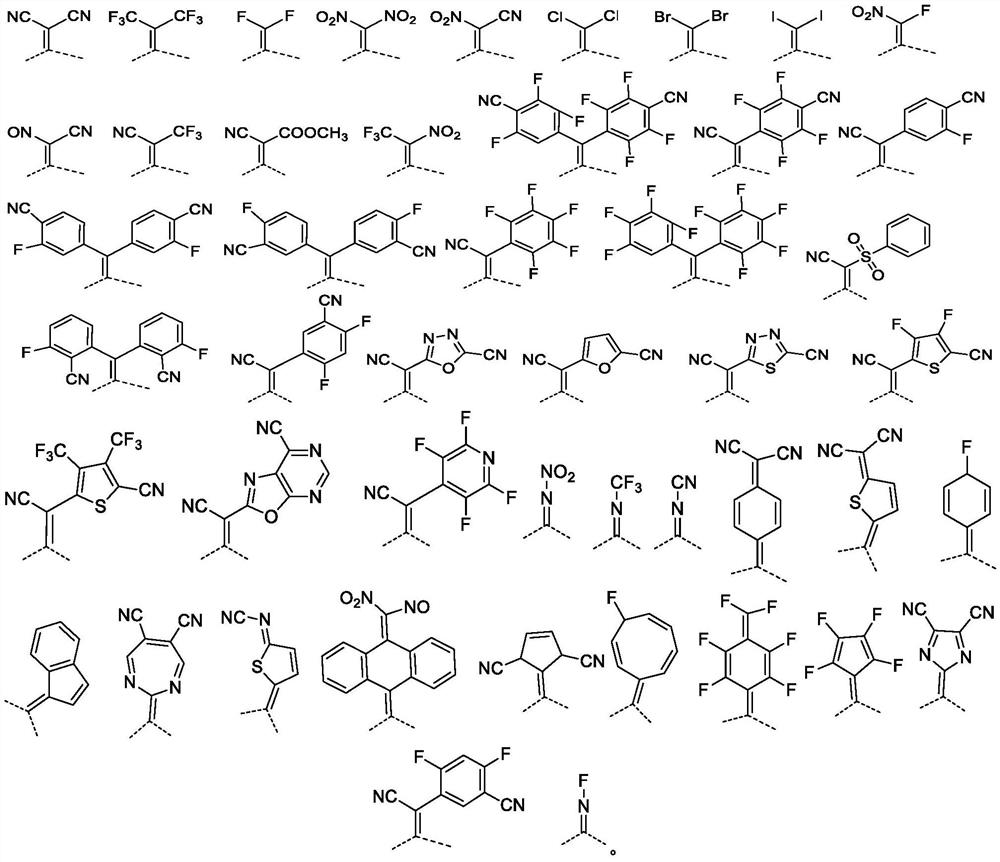

An organic compound, a selected technology, applied in the fields of compositions, mixtures, and organic compounds, can solve problems such as insufficient stability, reduced lifetime of organic light-emitting diodes, and reduced lifetime, and achieve excellent hole transport properties and stability, and improve electrical conductivity. Luminescence efficiency and the effect of prolonging the life of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0147] Embodiment 1, the synthetic reaction of compound P-1

[0148]

[0149] Synthesis of compound A2:

[0150] Compound A1 (2.02g, 10mmol), sodium periodate (NaIO 4 17.6g, 81.8mmol), ruthenium trichloride (RuCl 3. XH 2 (0, 0.25g, 1.2mmol), acetonitrile 40ml, dichloromethane 40ml, and distilled water 50ml stirred overnight at 30-40 degrees Celsius, the reaction product was cooled to room temperature, and 200ml distilled water was added, then the precipitate formed by filtration under reduced pressure, Extract the filtrate with dichloromethane, and add anhydrous magnesium sulfate to it to remove moisture, then remove the solvent under reduced pressure, use dichloromethane as the eluent to make the residue pass through a silica gel column to obtain the product, and then remove the solvent under reduced pressure solvent and dry the product in vacuo to prepare the desired solid compound A2 (0.80 g, 31%), MS: [M+H] + =263.

[0151] Synthesis of compound P-1:

[0152] Tit...

Embodiment 2

[0153] Embodiment 2, the synthetic reaction of compound P-2

[0154]

[0155] Synthesis of compound A3:

[0156] Compound A2 (2.62g, 10mmol) prepared in Example 1 was dissolved in 80ml DMF, 7.4g (41.6mmol) NBS was dissolved in 73ml DMF solvent, and then the NBS solution was dripped into the bottom at a rate of 3-5 drops per second. solution, stir. At room temperature, after the dropwise addition, the reaction stopped, and 30ml of water was added dropwise to the reaction solution, recrystallized, and suction filtered to obtain product A3 (3.54g, 85%), MS: [M+H] + =418.

[0157] Synthesis of compound A4:

[0158] Titanium tetrachloride (9.34g, 50mmol), malononitrile (2.64g, 40mmol), compound A3 (4.18g, 10mmol) were refluxed and stirred in nitrogen-dried pyridine / dichloromethane for 24 hours, and then washed with cold concentrated hydrochloric acid Quenched, dichloromethane concentrated, then dried with anhydrous sodium sulfate, vacuum distillation, the residue was recryst...

Embodiment 3

[0161] Embodiment 3, the synthetic reaction of compound P-3

[0162]

[0163] Synthesis of Compound A2: Refer to Example 1.

[0164] Synthesis of Compound P-3:

[0165] Titanium tetrachloride (9.34g, 50mmol), compound A5 (4.36g, 40mmol), and compound A2 (2.63g, 10mmol) were stirred under reflux for 24 hours using dried pyridine / dichloromethane as a solvent under a nitrogen atmosphere, Then it was quenched with cold concentrated hydrochloric acid, concentrated in dichloromethane, then dried with anhydrous sodium sulfate, distilled under reduced pressure, and the residue was recrystallized with DCM / MeOH to obtain compound P-3 (2.57g, 41%), MS:[ M+H] + =627.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com