A kind of antibacterial and antifouling polymer brush and its preparation method and application

A polymer brush and antifouling technology, applied in the field of biomedical antibacterial materials, can solve the problems of complicated preparation methods, harsh conditions, and antibacterial activity to be improved, and achieve the effect of easy-to-obtain raw materials, mild synthesis conditions, and good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

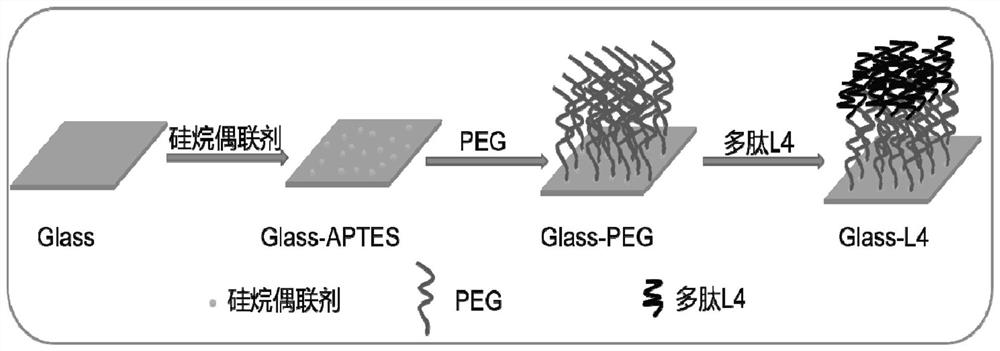

[0052] (1) Surface treatment of solid: Ultrasonic the glass sheet (referred to as Glass) in deionized water and ethanol successively for 60 minutes, N 2 Blow-dry in the air, then treat in the prepared piranha lotion (concentrated sulfuric acid: 30% hydrogen peroxide=7:3) for 6 hours, introduce hydroxyl groups on the solid surface, rinse with a large amount of water, N 2 Blow dry in air;

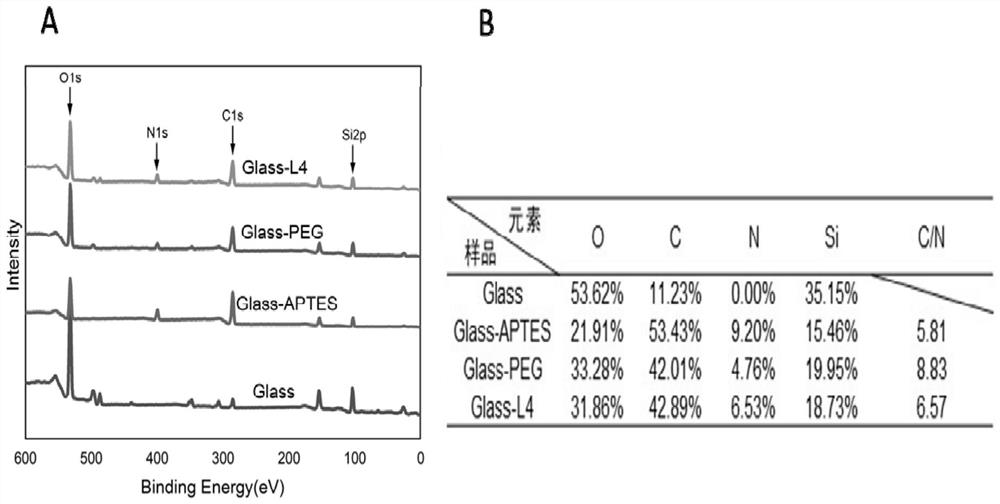

[0053] (2) Grafted silane coupling agent: immerse the solid that introduces the hydroxyl group into a toluene solution of 5% 3-aminopropyl-triethoxysilane (APTES), incubate overnight at 15-25°C, and then Washed three times with toluene, ethanol, deionized water and 2 Blow dry in the atmosphere to obtain the solid modified by silane coupling agent, which is recorded as Glass-APTES (XPS spectrogram such as figure 2 shown);

[0054] (3) Grafted polyethylene glycol: Weigh 10 mg of PEG-1K (molecular weight 1000), 7.7 mg of NHS, and 4.6 mg of EDC, mix them in MES buffer, stir at 15-25 °C for 30...

Embodiment 2

[0059] (1) Surface treatment of solids: Ultrasonic the glass sheet successively in deionized water and ethanol for 60 minutes, N 2 Blow dry in the atmosphere, then use oxygen plasma to treat the cleaned glass sheet for 30 seconds, introduce hydroxyl groups on the surface of the glass sheet, rinse with a large amount of water, N 2 Blow dry in air;

[0060] (2) Grafted silane coupling agent: Submerge the glass slide introduced with hydroxyl group in a toluene solution with a concentration of 2% 3-aminopropyl-triethoxysilane, incubate overnight at 15-25°C, and wash with toluene in turn , ethanol, deionized water three times and in N 2 Blow dry in the air to obtain a glass flake modified by a silane coupling agent;

[0061] (3) Grafting polyethylene glycol: Weigh 10 mg of PEG-1K, 7.7 mg of NHS, and 4.6 mg of EDC, mix them in MES buffer, stir at 15-25°C for 30 minutes, and mix the silane coupling agent modified The glass piece is submerged in the mixed solution, shaken for 24 ho...

Embodiment 3

[0065] (1) Surface treatment of solids: Ultrasonic the glass sheet successively in deionized water and ethanol for 60 minutes, N 2 Blow-dry in the air, then treat in the prepared piranha lotion (concentrated sulfuric acid: 30% hydrogen peroxide=7:3) for 6 hours, introduce hydroxyl groups on the surface of the glass sheet, rinse with a large amount of water, N 2 Blow dry in air;

[0066] (2) Grafted silane coupling agent: Submerge the glass slide introduced with hydroxyl group in a toluene solution with a concentration of 2% 3-aminopropyl-triethoxysilane, incubate overnight at 15-25°C, and wash with toluene in turn , ethanol, deionized water three times and in N 2 Blow dry in the air to obtain a glass flake modified by a silane coupling agent;

[0067] (3) Grafted polyethylene glycol: Weigh 5 mg of PEG (molecular weight 467.5), 7.7 mg of NHS, and 4.6 mg of EDC, mix them in MES buffer, stir for 30 min at 15-25 ° C, and couple the silane The agent-modified glass piece is immer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com