Process for preparing tea polyphenol

A technology of tea polyphenols and technology, which is applied in the field of tea polyphenols preparation technology, can solve the problems of expensive column packing materials, sealing components that cannot be used repeatedly, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

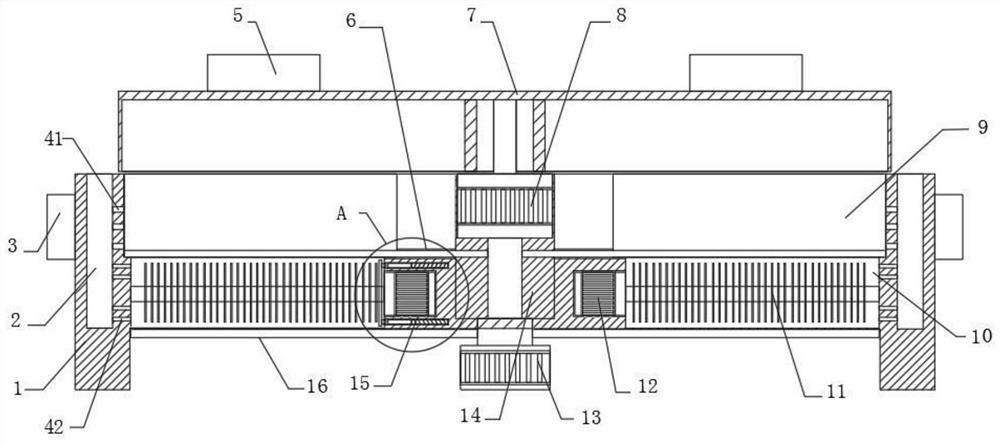

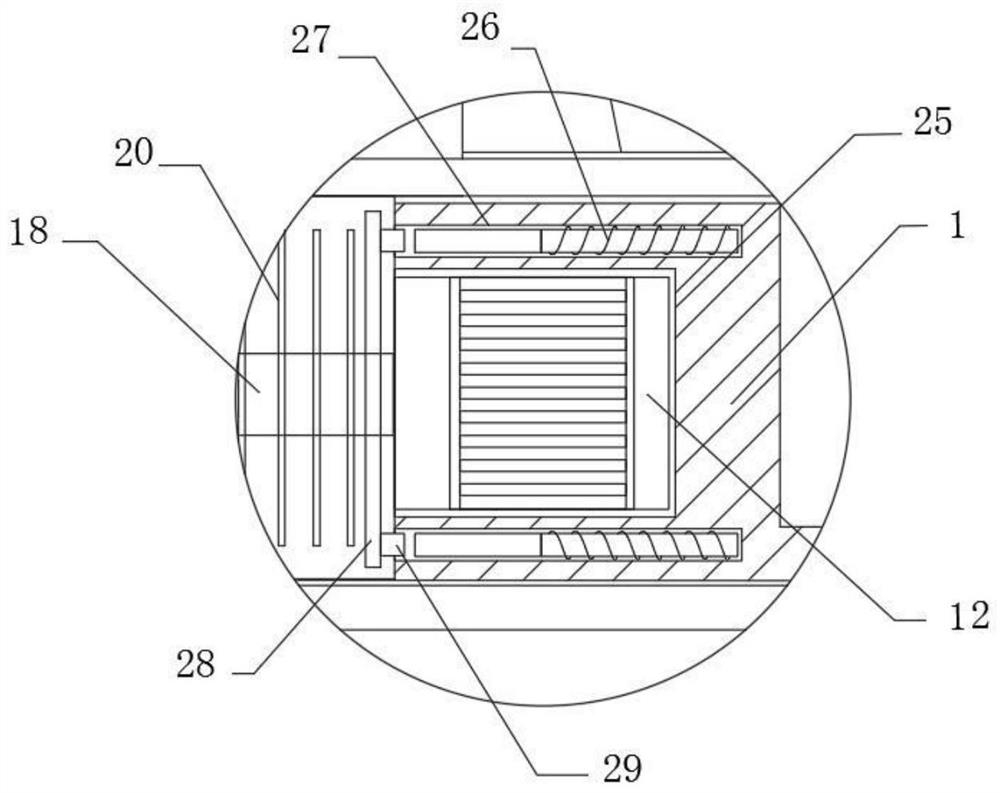

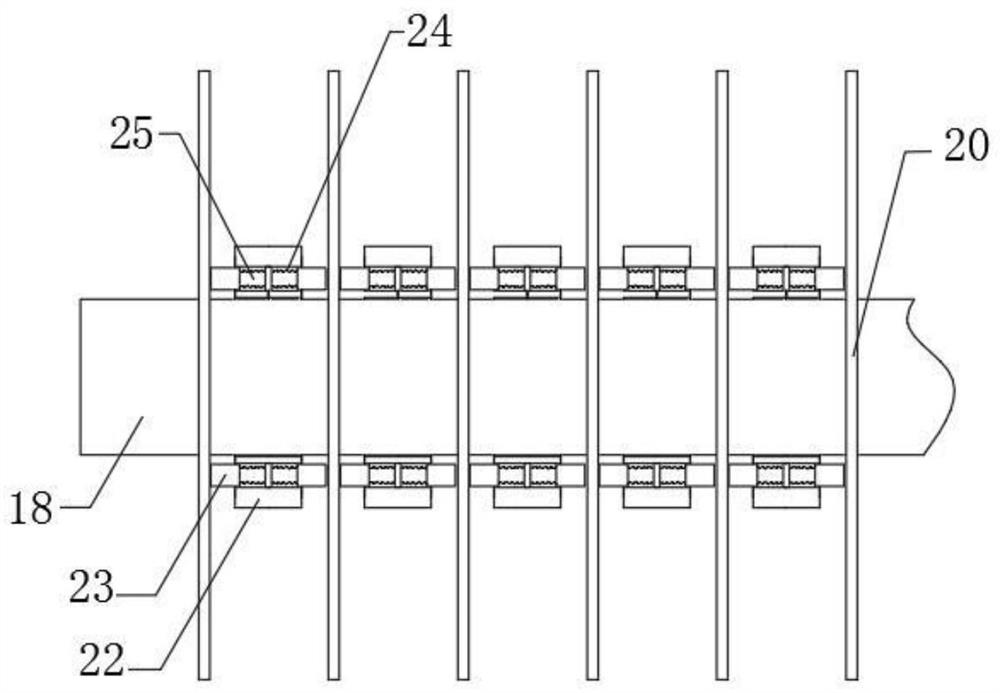

Image

Examples

Embodiment

[0044] A process for preparing tea polyphenols, comprising the following steps:

[0045] (1) Tea pretreatment: Pick fresh tea leaves and spread them out to dry, and then use the greening and crushing equipment to dry the tea industry under microwave until the water content reaches 70-75%, and then crush the spare tea leaves in a grinder to prepare tea powder. spare;

[0046] (2) Wall breaking: mix the spare tea powder and citric acid aqueous solution according to 1 tea powder kg: 20-40L, microwave leaching first, then add lignocellulosic hydrolase superfine powder for enzymolysis; then add pectinase superfine powder and Enzymatic hydrolysis with xylanase superfine powder, then boiled;

[0047] (3) Extraction: extract the enzymolysis solution obtained in step (2) in the reaction kettle at a pressure of 0.5-0.8MPa and a temperature of 90-100°C for 10-15min, then extract at an ultrasonic power of 80-100W for 5-8min, and filter Remove the slag, then centrifuge the filtrate, coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com