Anti-bioerosion wear-resistant recycled aggregate pervious concrete and preparation method thereof

A technology of permeable concrete and recycled aggregate, applied in ceramic products, solid waste management, other household appliances, etc., can solve the problems of resistance to biological erosion and wear resistance, and achieve the effects of low cost, extended service life and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

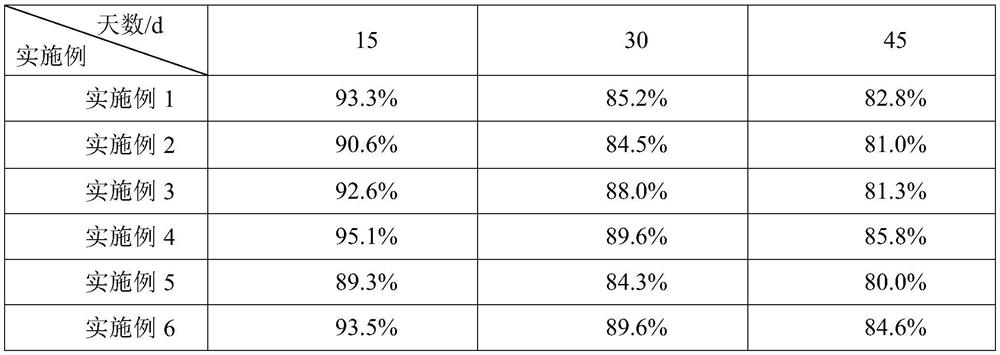

Examples

Embodiment 1

[0030] An anti-biological erosion wear-resistant recycled aggregate permeable concrete, comprising the following components in parts by weight: 1350 parts of recycled aggregate, 350 parts of cement, 30 parts of ultrafine slag powder, 26 parts of copper slag, 115 parts of water, and 0.20 parts of water agent, 25 parts of redispersible latex powder, 0.16 parts of cellulose ether, 2 parts of magnesium fluorosilicate, 3 parts of sodium silicate, and 0.5 part of copper sulfate.

Embodiment 2

[0032] An anti-biological erosion wear-resistant recycled aggregate permeable concrete, comprising the following components in parts by weight: 1350 parts of recycled aggregate, 360 parts of cement, 40 parts of ultrafine slag powder, 35 parts of copper slag, 105 parts of water, 0.17 parts of water agent, 25 parts of redispersible latex powder, 0.20 parts of cellulose ether, 4 parts of magnesium fluorosilicate, 3 parts of sodium silicate, and 3 parts of copper sulfate.

Embodiment 3

[0034] An anti-biological erosion wear-resistant recycled aggregate permeable concrete, comprising the following components in parts by weight: 1350 parts of recycled aggregate, 320 parts of cement, 25 parts of ultrafine slag powder, 45 parts of copper slag, 100 parts of water, 0.21 parts of water agent, 20 parts of redispersible latex powder, 0.18 parts of cellulose ether, 2.5 parts of magnesium fluorosilicate, 1-5 parts of sodium silicate, and 2.5 parts of copper sulfate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com