Amino cellulose and preparation method thereof

A cellulose and amino technology, applied in the field of amino cellulose and its preparation, can solve the problems of complex production process, harsh reaction conditions, long time consumption, etc., and achieve the effects of expanding the scope of application, improving added value and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

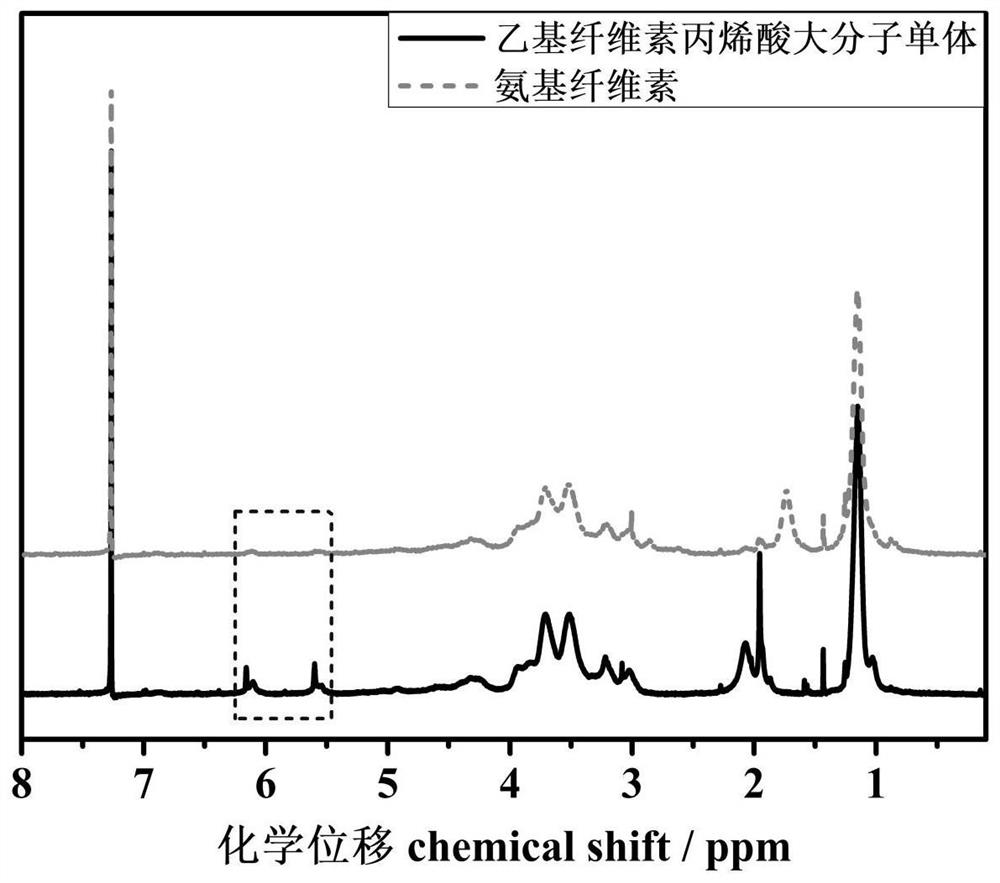

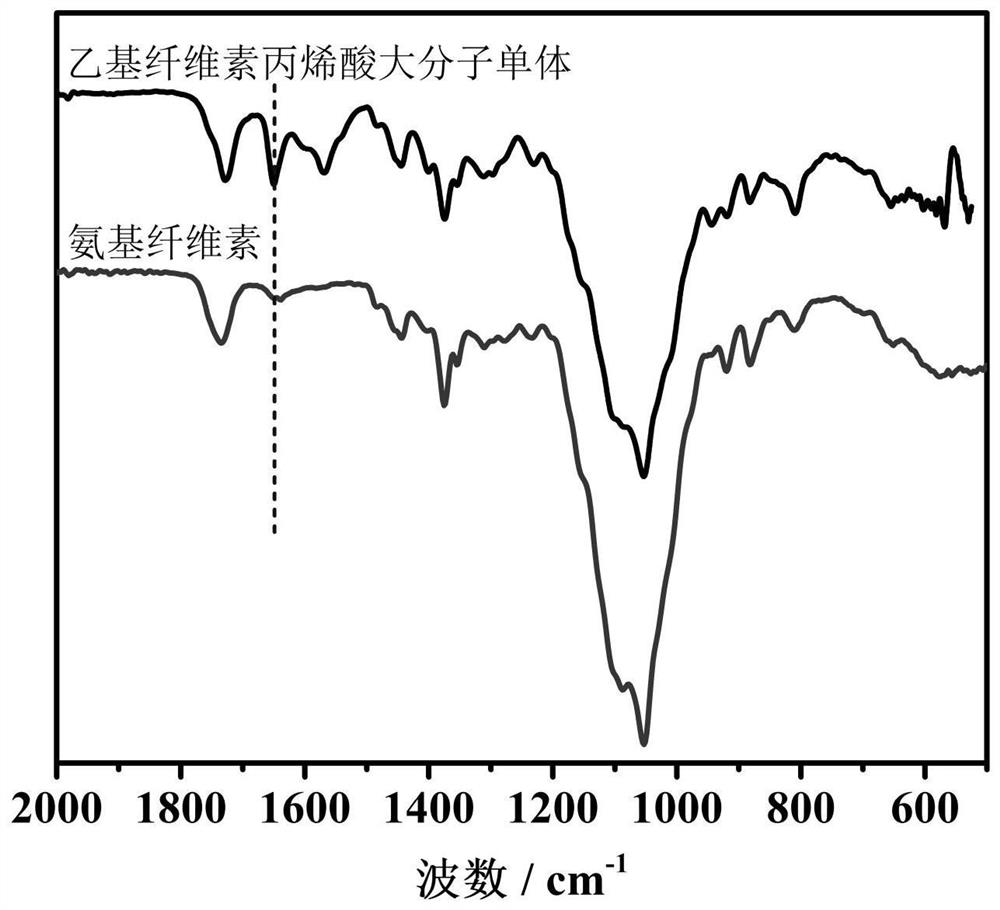

[0026] Embodiment 1: Utilize ethyl cellulose to prepare amino cellulose

[0027] The first step: ethyl cellulose, methacrylic anhydride, 4-dimethylaminopyridine in molar ratio [ethyl cellulose]: [methacrylic anhydride]: [4-dimethylaminopyridine] = 1: 1.2 : 0.3 was dissolved in tetrahydrofuran and reacted for 5 hours at 50°C to prepare ethyl cellulose acrylic acid macromer;

[0028] The second step: mix ethyl cellulose acrylic macromer, mercaptoethylamine, and azobisisobutyronitrile in molar ratio [ethyl cellulose acrylic macromer]: [mercaptoethylamine]: [azobis Isobutyronitrile]=1:1:0.03 was dissolved in ethanol, and after heating and reacting at 75°C for 5 hours, the product was precipitated in deionized water, filtered and dried to obtain aminocellulose with a yield of 90.4%.

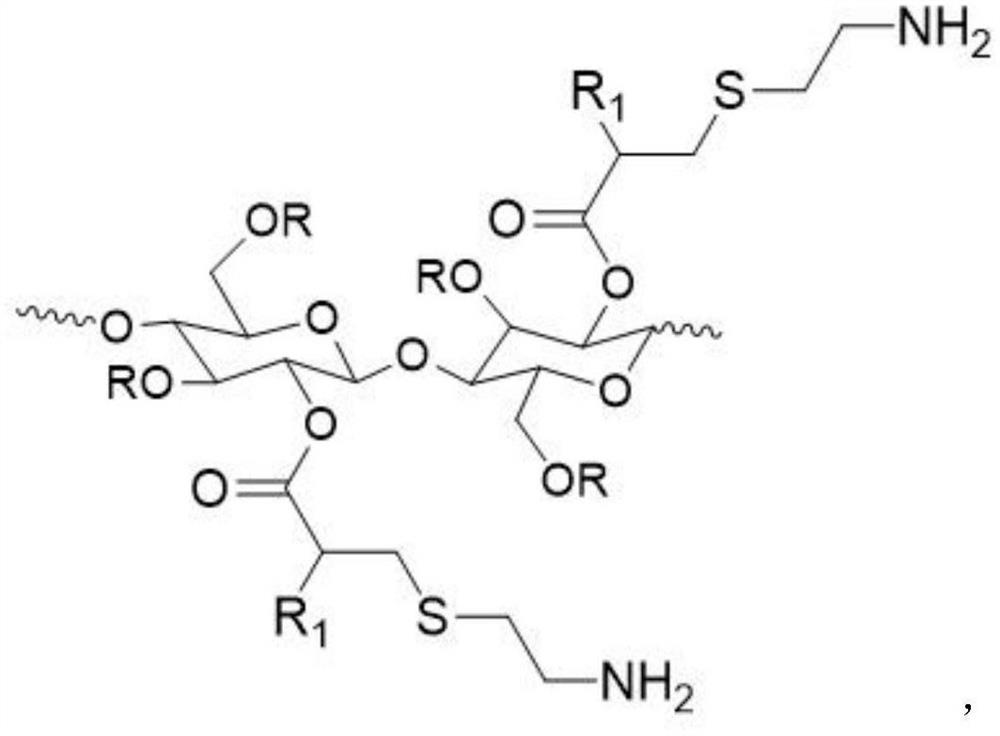

[0029] The preparation process reaction formula of the present embodiment is as follows:

[0030] first step

[0031]

[0032] Wherein, R is the characteristic functional group of the cellulose ...

Embodiment 2

[0038] Embodiment 2: utilize ethyl cellulose to prepare amino cellulose

[0039] Step 1: Dissolve ethyl cellulose, methacryloyl chloride, and triethylamine in tetrahydrofuran in a molar ratio [ethyl cellulose]: [methacrylic anhydride]: [triethylamine] = 1:1:0.3 React at 10°C for 5 hours to prepare ethyl cellulose acrylic acid macromer;

[0040] The second step: the molar ratio of ethyl cellulose acrylic acid macromer, mercaptoethylamine, and photoinitiator 907 [ethyl cellulose acrylic acid macromer]: [mercaptoethylamine]: [photoinitiator 907] =1:0.5:0.04 dissolved in ethanol at 2mW / cm 2 After being irradiated by an ultraviolet lamp for 12 hours, the product was precipitated in deionized water, filtered and dried to obtain aminocellulose with a yield of 89.2%.

Embodiment 3

[0042] Aminocellulose was prepared from microcrystalline cellulose.

[0043] R in this embodiment is H, -CH 3 any of the.

[0044]Step 1: Dissolve microcrystalline cellulose, methacrylic anhydride and triethylamine in DMAc / Prepare microcrystalline cellulose acrylic acid macromer by reacting at 40°C for 5 hours in LiCl system;

[0045] The second step: microcrystalline cellulose acrylic macromer, mercaptoethylamine, and azobisisobutyronitrile in molar ratio [ethyl cellulose acrylic macromer]: [mercaptoethylamine]: [azobis [isobutyronitrile]=1:2:0.04 was dissolved in DMSO, and after heating at 60°C for 5 hours, the product was precipitated in deionized water, filtered and dried to obtain aminocellulose with a yield of 86.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com