Preparation method of base film for ceramic capacitor release film

A technology of ceramic capacitors and release films, applied in the direction of chemical instruments and methods, applications, flat products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

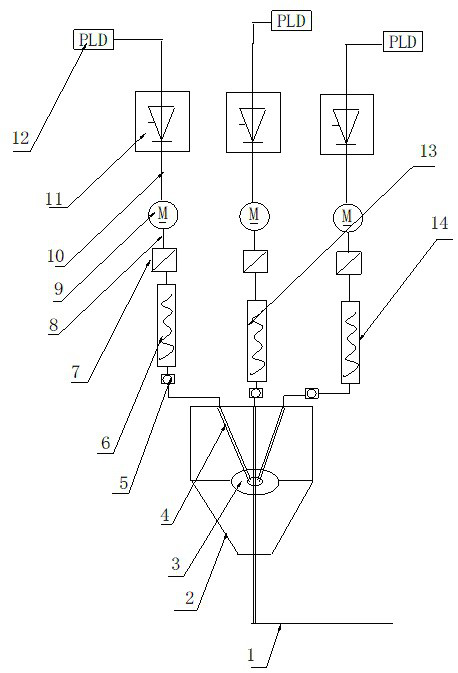

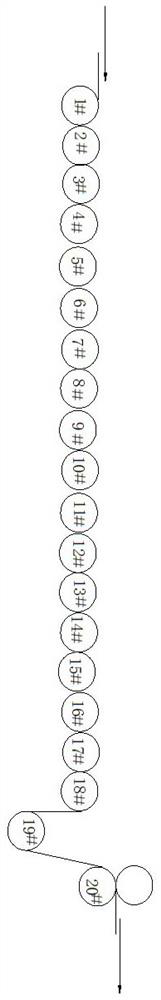

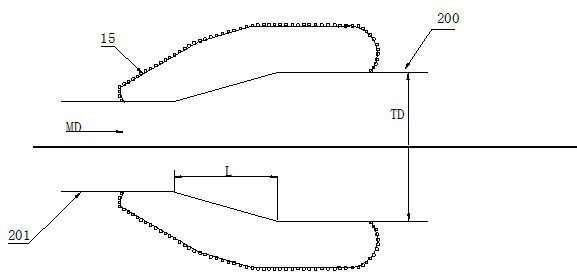

[0037] refer to Figure 1-5 , a method for preparing a base film for a ceramic capacitor release film, comprising a cast sheet pipeline 1, a die head 2, a co-extrusion system 3, a melt pipeline 4, a filter 5, a first extruder 6, a metering pump 7, a wire 8. DC motor 9, data wire 10, electronic component 11, control system 12, second extruder 13, third extruder 14, clamp 15, horizontal stretch width 200, film width 201; A method for preparing a base film for a ceramic capacitor release film, wherein a co-extrusion system 3 and a melt pipeline 4 are installed inside a die head 2; a metering pump 7 is connected to a DC motor 9 through a wire 8; a DC motor 9, electronic components 11, and a control system 12 is connected with a data wire 10; the casting pipeline 1 is installed at the lower end of the die head 2; the base film for the release film of the ceramic capacitor has three layers in structure, that is, ABA or ABC type, and the A layer solves the separation and opening prop...

Embodiment 2

[0048] Detection of DEG content in polyester chips:

[0049] In the production process of polyester, ethylene glycol undergoes its own synthesis reaction under high temperature conditions to form diethylene glycol. Diethylene glycol has the properties of part of ethylene glycol and enters the polyester chain in a manner similar to ethylene glycol. There are also ether bonds. Due to the replacement of some lipid bonds by ether bonds, the relatively regular chemical structure and relatively regular geometric structure of PET are destroyed, the conformation of PET molecules increases, and the flexibility of molecular chains increases, resulting in a decrease in melting point. The problem of poor light resistance and heat resistance, so it is very necessary to accurately determine PET.

[0050] Experimental equipment and experimental methods: gas chromatograph, chromatographic column; raw materials: ethanolamine, isopropanol, benzyl alcohol, diethylene glycol;

[0051] Accurately...

Embodiment 4

[0055] Experimental test of shrinkage rate of heat shrinkable film: The state adjustment of the sample should be carried out according to the regulations of GB / T2918-1998, the humidity is ℃, the adjustment time is not less than 0.5h, and the test is carried out under this condition: Experimental equipment: constant temperature bath, frame , steel ruler, blade, used to hold the liquid heat transfer medium, the volume should meet the test requirements; liquid heat transfer medium: choose heat transfer oil as the heat transfer medium, and the principle is to have no effect on the sample; frame: two metal mesh embedded The frame of the metal mesh is larger than the sample by more than 10mm; the distance between the two metal meshes is 1mm-3mm, which should not affect the free shrinkage of the sample; sample cutting: use a steel ruler with an accuracy of 0.5mm, a blade or a special tool , cut 3 samples of 100mm×100mm, mark the vertical and horizontal directions of the film; test pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com