Double-transition-metal-based composite liquid crystal material and preparation method thereof

A transition metal, liquid crystal material technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve problems such as agglomeration, graphene is expensive, and the preparation process is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

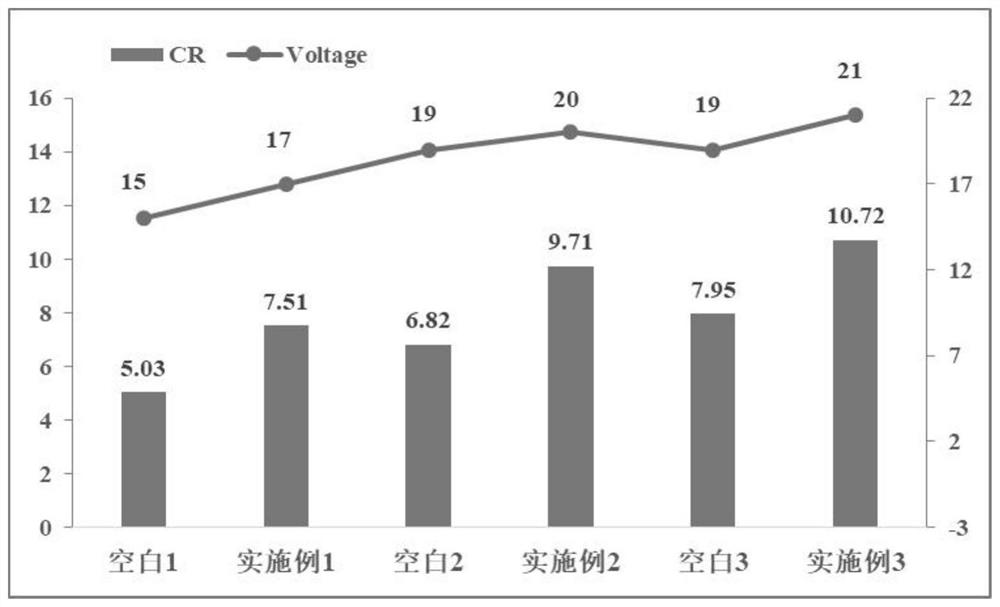

Embodiment 1

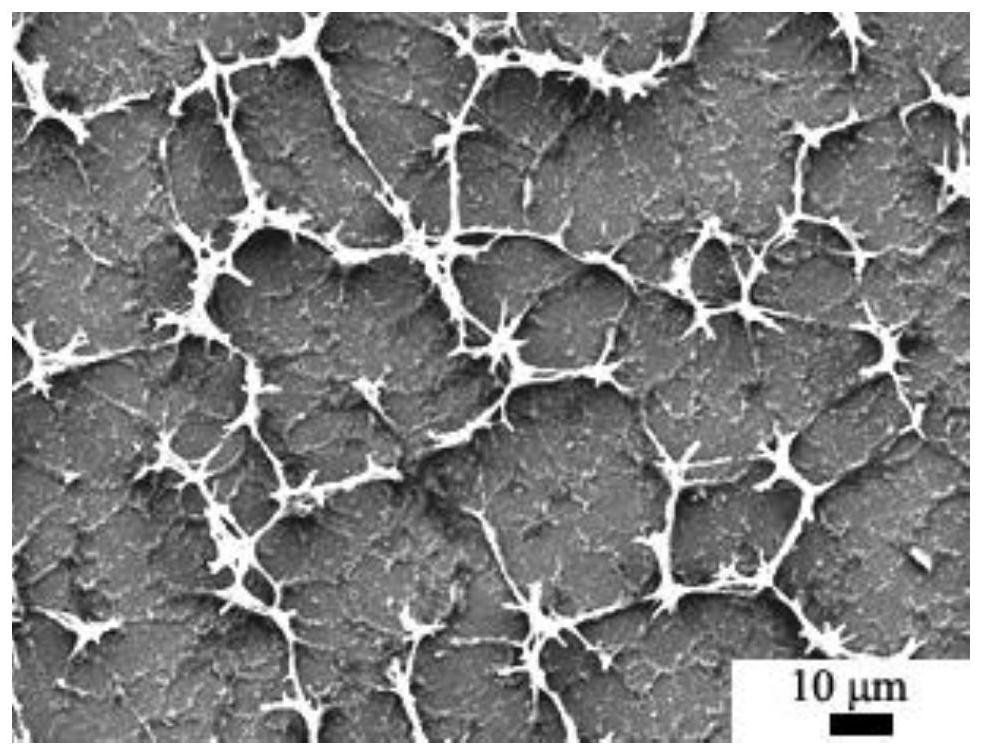

[0024] Weigh 180 parts of copper nitrate, 60 parts of titanium tetrachloride and 35 parts of 2-aminoterephthalic acid in a three-necked flask, then add 120 parts of dimethyl sulfoxide and 30 parts of n-butanol , continuously stirred for 15 minutes until completely dissolved, reacted at 45°C for 24 hours; centrifuged and filtered the mixed solution, washed the collected product three times with acetone, and freeze-dried for 48 hours to obtain Cu-Ti double-transition metal-based three-dimensional network nanoparticles;

[0025] Disperse the Cu-Ti double-transition metal-based three-dimensional network nanoparticles prepared above in acetone to prepare a mixed solution with a mass fraction of 0.5 wt%, transfer 5.2 parts to a three-necked flask, and perform ultrasonic dispersion for 30 minutes to obtain a mixture I stand by.

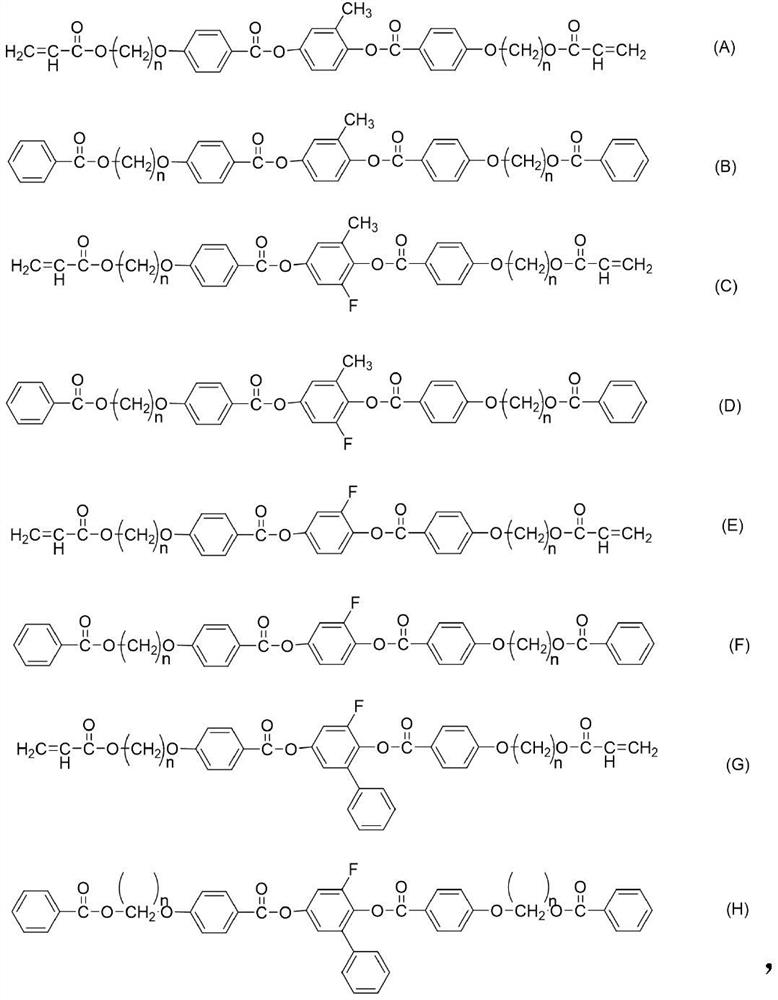

[0026] Subsequently, the liquid crystal polymer monomers A (n=2) and F (n=6), R5011, IRG369, EOEOEA, perylene, etc. are mixed according to the mass ratio of...

Embodiment 2

[0029] Weigh 220 parts of copper sulfate, 110 parts of silver nitrate and 165 parts of 2,5-diaminoterephthalic acid in a three-necked flask, then add 100 parts of N,N-dimethylformamide and 10 A portion of n-butanol was continuously stirred for 30 minutes until completely dissolved, and reacted at 80°C for 12 hours; the mixture was centrifuged and filtered, and the collected product was washed 3 times with acetone, and freeze-dried for 72 hours to obtain a Cu-Ag double-transition metal-based three-dimensional mesh nanoparticles;

[0030] Disperse the Cu-Ag double-transition metal-based three-dimensional network nanoparticles prepared above in acetone to prepare a mixed solution with a mass fraction of 0.5 wt%, and take 5.1 parts of it in a three-necked flask for ultrasonic dispersion for 50 minutes to obtain a mixture I stand by.

[0031] Subsequently, the liquid crystal polymer monomer A (n=6), R2011, IRG2959, IDA, perylene, etc. are fully mixed according to the ratio of 45 p...

Embodiment 3

[0034] Weigh respectively 260 parts of copper sulfate, 190 parts of chromium chloride and 51 parts of 4-(4-pyridyl) benzoic acid in a three-necked flask, then add 190 parts of N,N-dimethylformamide and 20 parts of n-butanol, continuously stirred for 60 minutes until completely dissolved, and reacted at 180°C for 48 hours; centrifuged and filtered the mixed solution, washed the collected product three times with acetone, and freeze-dried for 72 hours to obtain Cu-Cr double transition metal base Three-dimensional network nanoparticles;

[0035] Disperse the Cu-Cr double-transition metal-based three-dimensional network nanoparticles prepared above in acetone to prepare a mixed solution with a mass fraction of 5.5 wt%. Take 1.3 parts in a three-necked flask and perform ultrasonic dispersion for 20 minutes to obtain a mixture I stand-by.

[0036] Subsequently, the liquid crystal polymer monomers B (n=6) and E (n=2), R1011, IRG907, PETA, Rhodamine 123, etc. were ratioed as 10 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com