Continuous production method of potato fermented beverage and potato residue powder and products prepared by continuous production method

A technology for fermented beverages and potatoes, applied in the directions of bacteria, bifidobacteria, food science, etc. used in food preparation, to achieve the effects of increasing immunity and nutrient absorption capacity, increasing content, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

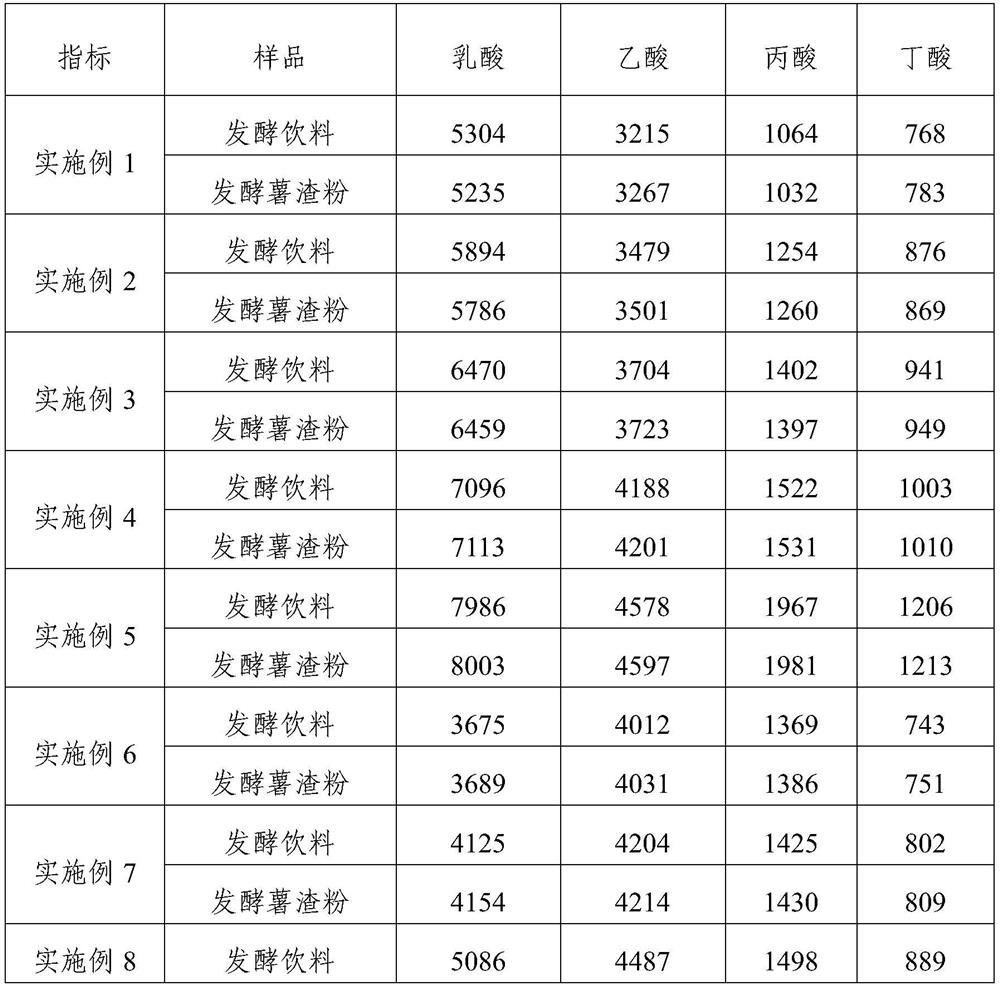

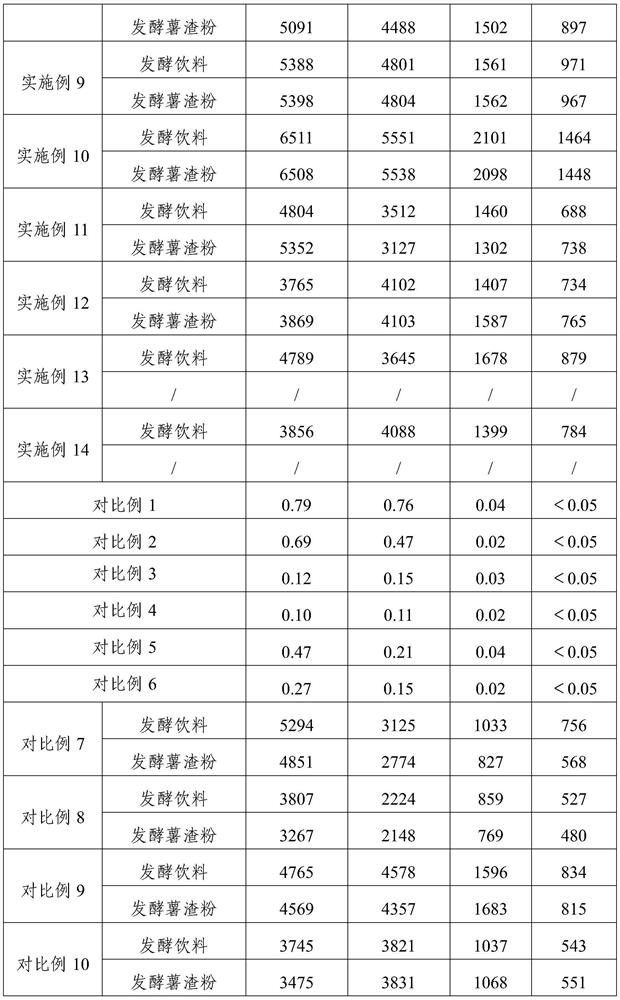

Examples

Embodiment 1

[0049] This embodiment provides a method for continuous production of potato fermented beverage and potato residue powder and the product prepared therefrom. The preparation method comprises the following steps:

[0050] 1) Mix 55 parts of whole sweet potato and water evenly at a mass ratio of 5:10, then heat up to 95°C, add amylase at 250 U / g of whole sweet potato, and incubate for 60 minutes;

[0051] 2) After the temperature of the mixture in step 1) is lowered to 55°C, add alkaline protease at 150 U / g whole sweet potato and incubate for 90 minutes;

[0052] 3) Heat the mixture obtained in step 2) at 110°C for 28 minutes, and set aside;

[0053] 4) Use the heated mixed solution obtained in step 3) as raw material, and when the temperature drops to 37°C, inoculate 2 parts of Pediococcus pentosaceae bacterial suspension, the concentration of viable bacteria in the bacterial suspension is 10 8 cfu / mL, cultured at 37°C for 48h;

[0054] 5) Take the fermentation product of Ped...

Embodiment 2

[0056] This embodiment provides a method for continuous production of potato fermented beverage and potato residue powder and the product prepared therefrom. The preparation method comprises the following steps:

[0057] 1) Mix 55 parts of whole sweet potato and water evenly at a mass ratio of 5:10, then heat up to 95°C, add amylase at 250 U / g of whole sweet potato, and incubate for 60 minutes;

[0058] 2) After the temperature of the mixture in step 1) is lowered to 55°C, add alkaline protease at 150 U / g whole sweet potato and incubate for 90 minutes;

[0059] 3) Heat the mixture obtained in step 2) at 115°C for 30 minutes, and set aside;

[0060] 4) Use the heated mixed solution obtained in step 3) as the raw material, and when the temperature drops to 37°C, inoculate 2 parts of Lactobacillus rhamnosus suspension, the concentration of viable bacteria in the suspension is 10 8 cfu / mL, cultured at 37°C for 48h;

[0061] 5) Take the Lactobacillus rhamnosus fermentation produc...

Embodiment 3

[0063] This embodiment provides a method for continuous production of potato fermented beverage and potato residue powder and the product prepared therefrom. The preparation method comprises the following steps:

[0064] 1) Mix 55 parts of whole sweet potato and water evenly at a mass ratio of 5:10, then heat up to 95°C, add amylase at 250 U / g of whole sweet potato, and incubate for 60 minutes;

[0065] 2) After the temperature of the mixture in step 1) is lowered to 55°C, add alkaline protease at 150 U / g whole sweet potato and incubate for 90 minutes;

[0066] 3) Heat the mixture obtained in step 2) at 105°C for 40 minutes, and set aside;

[0067] 4) Use the heated mixed solution obtained in step 3) as raw material, and when the temperature drops to 37°C, inoculate 2.5 parts of Leuconostoc enterococci bacterial suspension, the concentration of viable bacteria in the bacterial suspension is 10 8 cfu / mL, cultured at 37°C for 48h;

[0068] 5) Take the Leuconostoc enterococci f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com