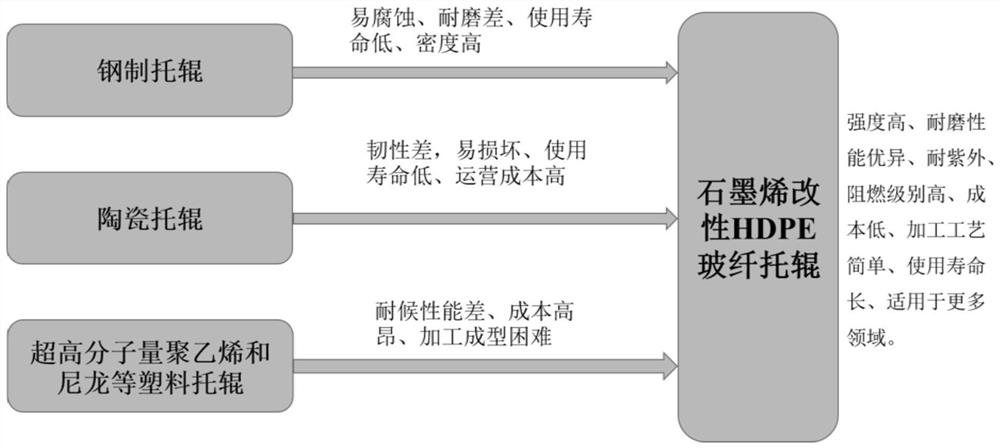

Graphene modified high-density polyethylene composite material for carrier roller and preparation method of graphene modified high-density polyethylene composite material

A high-density polyethylene and graphene modification technology, applied in the field of polymer processing, can solve the problems of difficult to guarantee size, poor high temperature resistance, large volume shrinkage, etc., and achieve toughness that is not easy to break, excellent wear resistance, and production The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

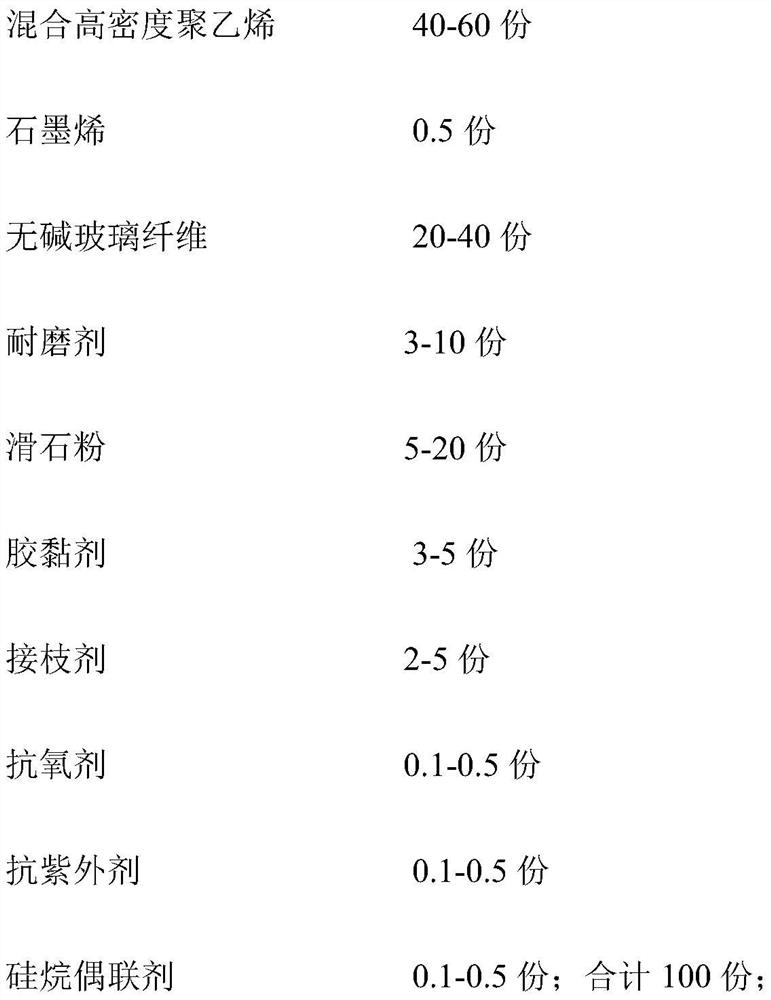

[0066] A graphene-modified high-density polyethylene composite material for an idler roller of the present invention, the raw material components and the proportioning by weight are:

[0067] 50 parts of high-melt index (18g / 10min) high-density polyethylene, 10 parts of low-melt index (0.8g / 10min) high-density polyethylene, 0.5 part of graphene, 22.5 parts of alkali-free glass fiber (13 microns in diameter), graphite powder 5 parts, 5 parts of talcum powder (2000 mesh), 3 parts of adhesive, 3 parts of grafting agent, 0.5 part of antioxidant, 0.1 part of anti-ultraviolet agent, 0.4 part of silane coupling agent.

[0068] Among them, graphene is powder, and its BET is 250m 2 / g, the particle size D50 is 25 μm;

[0069] The adhesive is A490;

[0070] The grafting agent is maleic anhydride grafted PE;

[0071] The antioxidant is antioxidant 1010;

[0072] The anti-ultraviolet agent is UV531;

[0073] The silane coupling agent is KH550.

[0074] A kind of carrier roller of th...

Embodiment 2

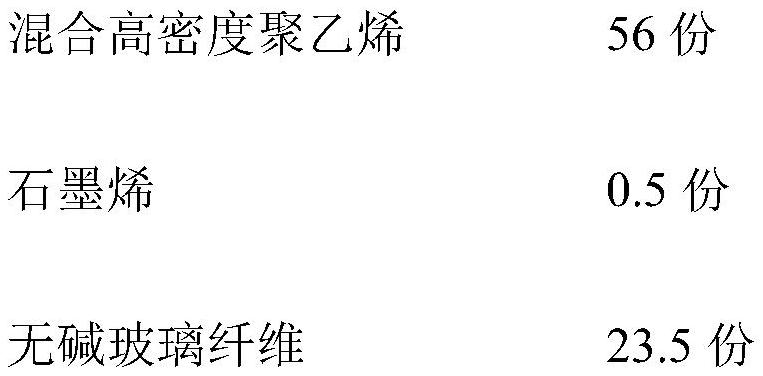

[0079] A graphene-modified high-density polyethylene composite material for an idler roller of the present invention, the raw material components and the proportioning by weight are:

[0080] 30 parts of high-melt index (18g / 10min) high-density polyethylene, 10 parts of low-melt index (0.8g / 10min) high-density polyethylene, 0.5 part of graphene, 22.5 parts of alkali-free glass fiber (13 microns in diameter), disulfide 10 parts of molybdenum, 20 parts of talc powder (2000 mesh), 3 parts of adhesive, 3 parts of grafting agent, 0.1 part of antioxidant, 0.5 part of anti-ultraviolet agent, 0.4 part of silane coupling agent.

[0081] in,

[0082] Graphene is powder, its BET is 250m 2 / g, the particle size D50 is 25 μm;

[0083] The adhesive is A490;

[0084] The grafting agent is maleic anhydride grafted PE;

[0085] The antioxidant is antioxidant 168;

[0086] The anti-ultraviolet agent is UV770;

[0087] The silane coupling agent is KH560.

[0088] A kind of carrier roller ...

Embodiment 3

[0093] A graphene-modified high-density polyethylene composite material for an idler roller of the present invention, the raw material components and the proportioning by weight are:

[0094] 31 parts of high-melt index (18g / 10min) high-density polyethylene, 10 parts of low-melt index (0.8g / 10min) high-density polyethylene, 0.5 parts of graphene, 40 parts of alkali-free glass fiber (13 microns in diameter), 3 parts of PTFE 7.5 parts, 7.5 parts of talcum powder (2000 mesh), 5 parts of adhesive, 2 parts of grafting agent, 0.2 part of antioxidant, 0.3 part of anti-ultraviolet agent, 0.5 part of silane coupling agent.

[0095] Among them, graphene is powder, and its BET is 250m 2 / g, the particle size D50 is 25 μm;

[0096] The adhesive is A490;

[0097] The grafting agent is maleic anhydride grafted PE;

[0098] The antioxidant is antioxidant 1010;

[0099] The anti-ultraviolet agent is UV531;

[0100] The silane coupling agent is KH560.

[0101] A kind of carrier roller of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com