Preparation method of magnetic particle-enriched anticorrosion-antifouling integrated self-repairing microcapsule

A technology of self-healing microcapsules and magnetic particles, which is applied in the direction of microcapsule preparation, microsphere preparation, anti-corrosion coatings, etc., can solve the problems of relatively harsh curing conditions, affecting the overall physical properties of the coating, and increasing the cost of the coating. Improve the release rate and repair effect, enhance the anti-corrosion and anti-fouling performance, and ensure the effect of running stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

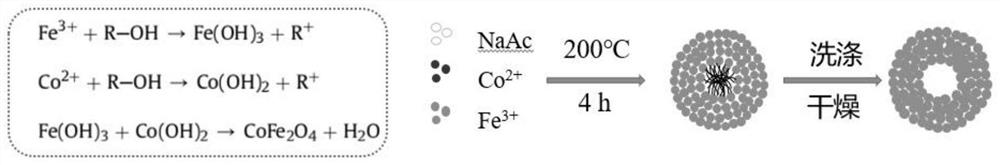

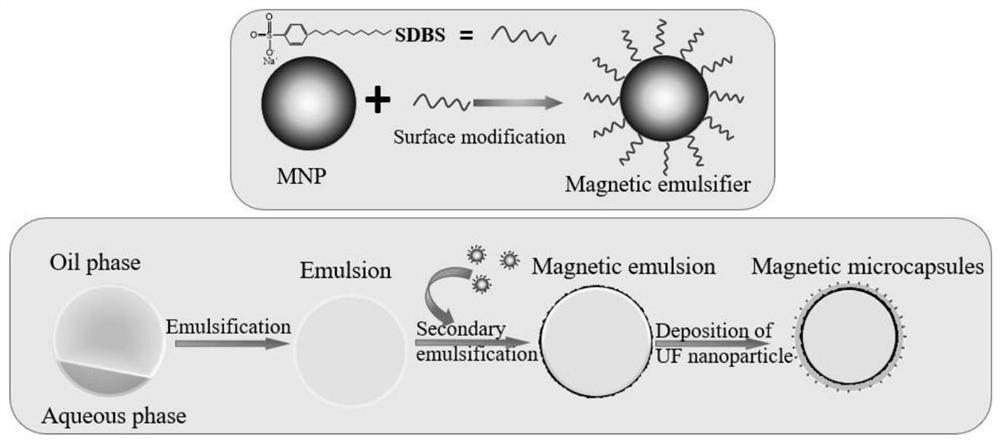

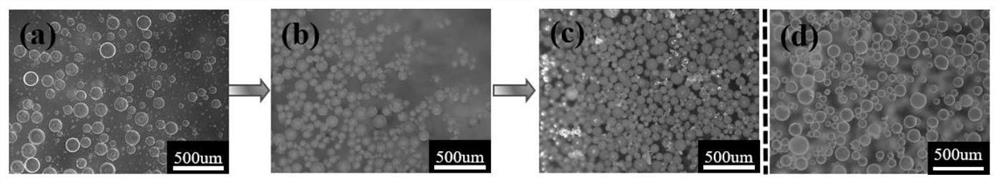

[0036] The process of the magnetic particle enrichment anti-corrosion and anti-fouling integrated self-repairing microcapsule preparation method involved in this embodiment includes two steps: preparing magnetic nanospheres and preparing self-repairing microcapsules:

[0037] (1) Preparation of magnetic nanospheres:

[0038] (1) FeCl 3 ·6H 2 O, CoCl 2 ·6H 2 O and sodium acetate are added successively in the mixed solution that ethylene glycol and diethylene glycol form, stir at room temperature, obtain No. 1 mixed solution;

[0039] (2) Add SDBS (sodium dodecylbenzene sulfonate) into No. 1 mixed solution and stir to obtain No. 2 mixed solution;

[0040] (3) Transfer the No. 2 mixed solution into a 100ml reaction kettle, place it in a vacuum drying oven and react for 6-10h in a vacuum environment at a temperature of 200°C, and then cool to room temperature to obtain the No. 3 mixed solution;

[0041] (4) Carry out magnetic separation to the No. 3 mixed solution with a magn...

Embodiment 2

[0052] The process of the magnetic particle enrichment anti-corrosion and anti-fouling integrated self-repairing microcapsule preparation method involved in this embodiment includes two steps: preparing magnetic nanospheres and preparing self-repairing microcapsules:

[0053] (1) Preparation of magnetic nanospheres: same as in Example 1;

[0054] (2) Preparation of self-healing microcapsules:

[0055] (1) Add 8g of OP-10 and 2g of PVA into 1000ml of ultrapure water, stir until completely dissolved and uniformly dispersed with a stirring disperser to obtain No. 4 mixed solution;

[0056] (2) Add 20g urea, 2g ammonium chloride and 2g resorcinol successively in No. 4 mixed solution, after dissolving, after the dilute hydrochloric acid aqueous solution that is 1% with mass percentage concentration is adjusted to 2.5 after the pH value, carry out acidification, Obtain No. 5 mixed solution;

[0057] (3) Add 20 g of tung oil and 5 g of phenolic amide into the No. 5 mixed solution, ...

Embodiment 3

[0063] The process of the magnetic particle enrichment anti-corrosion and anti-fouling integrated self-repairing microcapsule preparation method involved in this embodiment includes two steps: preparing magnetic nanospheres and preparing self-repairing microcapsules:

[0064] (1) Preparation of magnetic nanospheres: same as in Example 1;

[0065] (2) Preparation of self-healing microcapsules:

[0066] (1) Add 10g of OP-10 and 1g of PVA into 1000ml of ultrapure water, and stir until completely dissolved and uniformly dispersed with a stirring disperser to obtain No. 4 mixed solution;

[0067] (2) Add 20g urea, 2g ammonium chloride and 2g resorcinol successively in No. 4 mixed solution, after dissolving, after the dilute hydrochloric acid aqueous solution that is 1% with mass percent concentration adjusts pH value to 3, carry out acidification, Obtain No. 5 mixed solution;

[0068] (3) Add 40 g of tung oil and 10 g of phenolic amide to the No. 5 mixed solution, stir until the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com