Non-fullerene electron acceptor material and organic photovoltaic cell

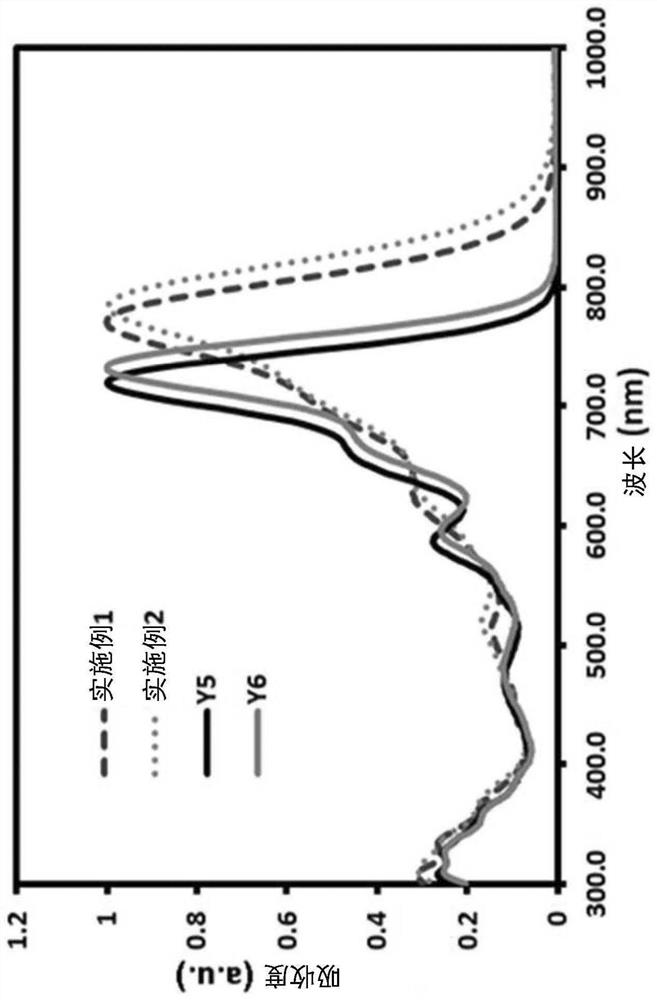

An electron acceptor material, non-fullerene technology, applied in photovoltaic power generation, organic chemistry, electric solid-state devices, etc., can solve problems such as red shift of absorption range, toxicity of raw materials and pollution of production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

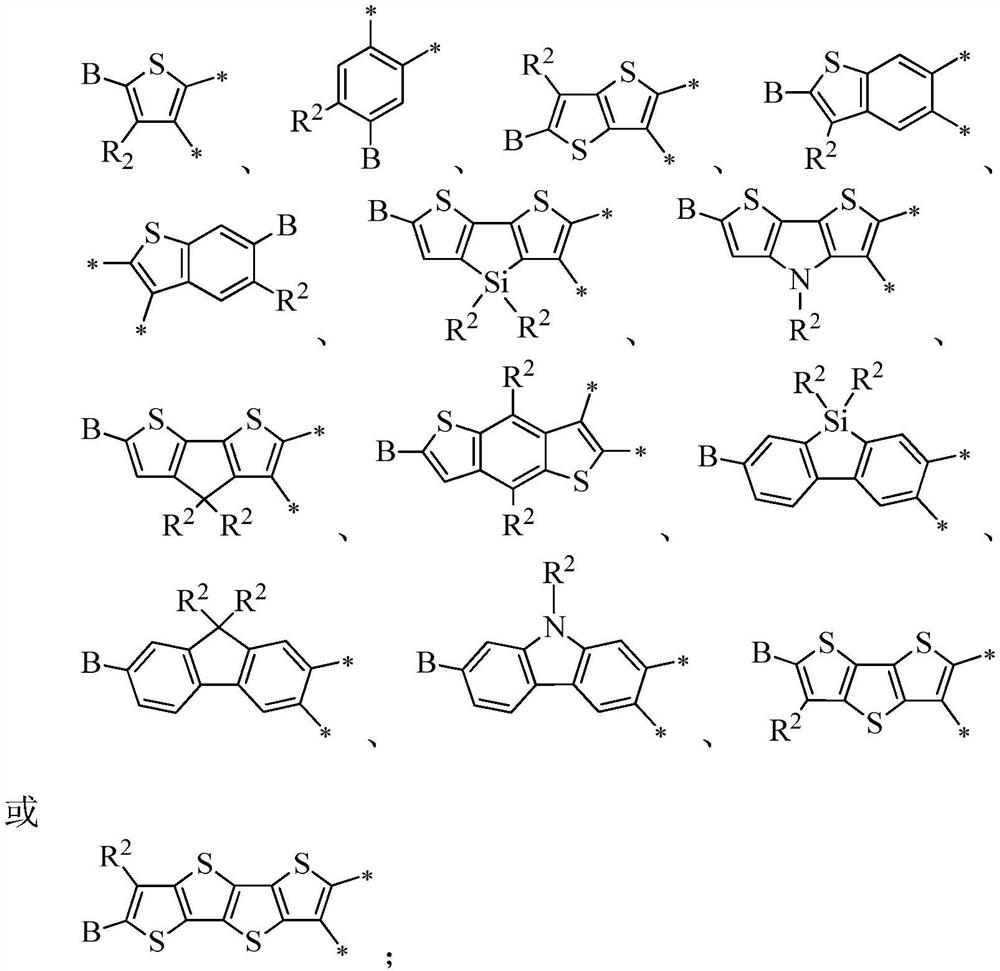

Method used

Image

Examples

Embodiment 1 and 2

[0077] Preparation of non-fullerene electron acceptor materials

Embodiment 1

[0078] The preparation process of the non-fullerene electron acceptor materials in Examples 1 and 2 is shown in the following reaction formula I (Example 1) and reaction formula II (Example 2).

[0079] [Reaction Formula I]

[0080]

[0081] [Reaction II]

[0082]

[0083] Compound 1

[0084]

[0085] The preparation method of compound 1:

[0086] 4,7-dibromo-benzothiadiazole (20 g, 68.034 mmol) was dissolved in ethanol (EtOH) (200 mL), and sodium borohydride (NaBH 4 ) (10.3 g, 272.14 mmol) and heated to reflux for 4 hours. Cool after the reaction, and extract with dichloromethane, water, and alkaline water. The organic layer was dried over anhydrous magnesium sulfate, filtered, and concentrated to dryness with a cyclone concentrator to obtain compound 1 (12.5 g, yield: 69%) as a light yellow solid.

[0087] Compound 2

[0088]

[0089] The preparation method of compound 2:

[0090] Compound 1 (2g, 7.52mmol) was dissolved in ethanol (20mL) and charged into a...

Embodiment 2

[0116]

[0117] The preparation method of embodiment 2:

[0118] Add compound 8 (0.3g, 0.28mmol) and 2F-IC (compound 10) (0.32g, 1.40mmol) into a 100mL round bottom bottle, then add 30mL of chloroform to dissolve, slowly drop into 1mL of pyridine, and heat to reflux under nitrogen protection for 2 Hours, after the reaction was completed, it was cooled, concentrated and sucked to dryness with a cyclone concentrator. Then, the solid was precipitated with methanol, and then purified by silica gel column chromatography (petroleum ether / chloroform). After vacuum drying, a dark blue solid was obtained which was Example 2 (0.3 g, yield: 73%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com