Preparation method of spherical crystal calcined bone

A calcined bone, spherical technology, applied in medical science, prosthesis, tissue regeneration, etc., can solve the problems of poor permeability, damage to extracellular matrix, high price, etc., to achieve improved biocompatibility, high biocompatibility, The effect of material strength enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

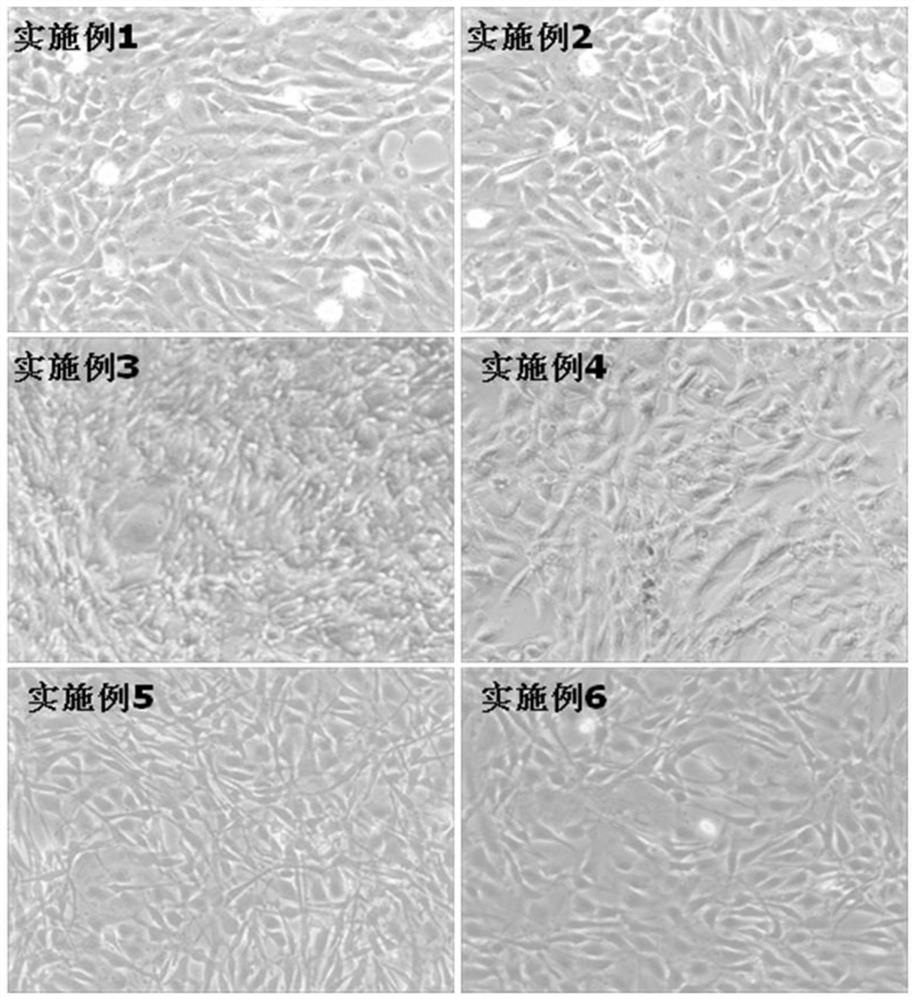

Embodiment 1

[0029] A method of preparing a spherical crystal calciner, comprising the steps of:

[0030] (1) Take the soft tissue, rough cut, boil 15 min, cool down to room temperature; then rocking at 1.0 mol / l NaOH solution 25 min, purified water Ultrasound 15min, repeating the above cleaning step 2;

[0031] (2) at 1.2% h 2 O 2 The aqueous solution was cleaned for 25 min, then washed with purified water for 20 min, repeating the above cleaning step 2 times;

[0032] (3) The use of the allogeneic bone prepared by step (2) is dried, placed in a muffle furnace, raised to 650 ° C, maintaining 6 h, cooled with the furnace;

[0033] (4) Immersion of the calcined bone is immersed in a mixed solution of sodium triophosphate and hydrogen phosphate, soaked in a water bath of 70 ° C for 70 h; in the mixed solution of sodium trimophosphate and hydrogen phosphate, three The concentration of sodium polyphosphate is 0.10 mol / L, the concentration of hydrogen phosphate is 0.25 mol / L, and the solution...

Embodiment 2

[0036] A method of preparing a spherical crystal calciner, comprising the steps of:

[0037] (1) Take the soft tissue, coarse cut, boiled for 12min, cool down to room temperature; then rocking at 0.7 mol / l NaOH solution, purified water ultrasound washed 18 min, repeating the above cleaning step 3 times;

[0038] (2) at 0.9% h 2 O 2 The aqueous solution was cleaned for 28 min and then washed with purified water for 18 min, repeating the above cleaning step 3 times;

[0039] (3) The use of the allogeneic bone prepared by step (2) is dried, placed in a muffle furnace, raised to 610 ° C, maintaining 8 h, cooled with the chain;

[0040] (4) Immersion of the calcined bone is immersed in a mixed solution of sodium trimophosphate and hydrogen phosphate, soaking 80 h in a water bath at 60 ° C; a mixed solution of sodium tripolyphosphate and a mixed solution of hydrogen phosphate, three The concentration of sodium polyphosphate is 0.05 mol / L, and the concentration of hydrogen phosphate ...

Embodiment 3

[0043] A method of preparing a spherical crystal calciner, comprising the steps of:

[0044] (1) Take the soft tissue, coarse cut, boiled for 18 min, cool down to room temperature; then rocking at 1.2 mol / l NaOH solution 20 min, purified water ultrasound 20min, repeating the above cleaning step;

[0045] (2) at 1.4% h 2 O 2 The aqueous solution was cleaned for 20 min, then washed with purified water for 25 minutes, repeating the above cleaning step 1;

[0046] (3) The use of the allogeneic bone prepared by step (2) is dried, placed in a muffle furnace, raised to 700 ° C, maintaining 5 h, cooled with the furnace;

[0047](4) Immersing the calcined bone strip in a mixed solution of tripolyphosphate and hydrogen phosphate dodium, soaked in a water bath of 78 ° C for 65 h; in the mixed solution of sodium trimophosphate and hydrogen phosphate, three The concentration of sodium polyphosphate is 0.13 mol / L, the concentration of hydrogen phosphate is 0.33 mol / L, and the solution pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com