Preparation method and application of ammonia borane hydrolysis hydrogen production catalyst

A technology for hydrogen production and catalysts by hydrolysis, applied in chemical instruments and methods, physical/chemical process catalysts, hydrogen production, etc., can solve problems such as danger and high cost, and achieve easy operation, high porosity, and abundant mesopores structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

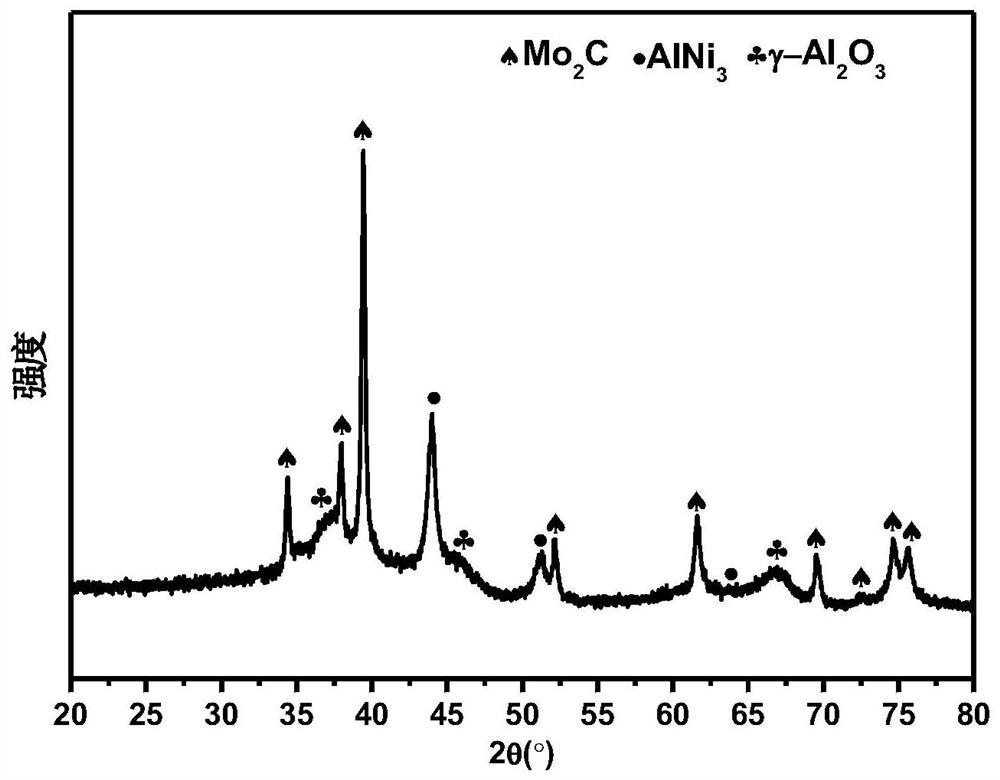

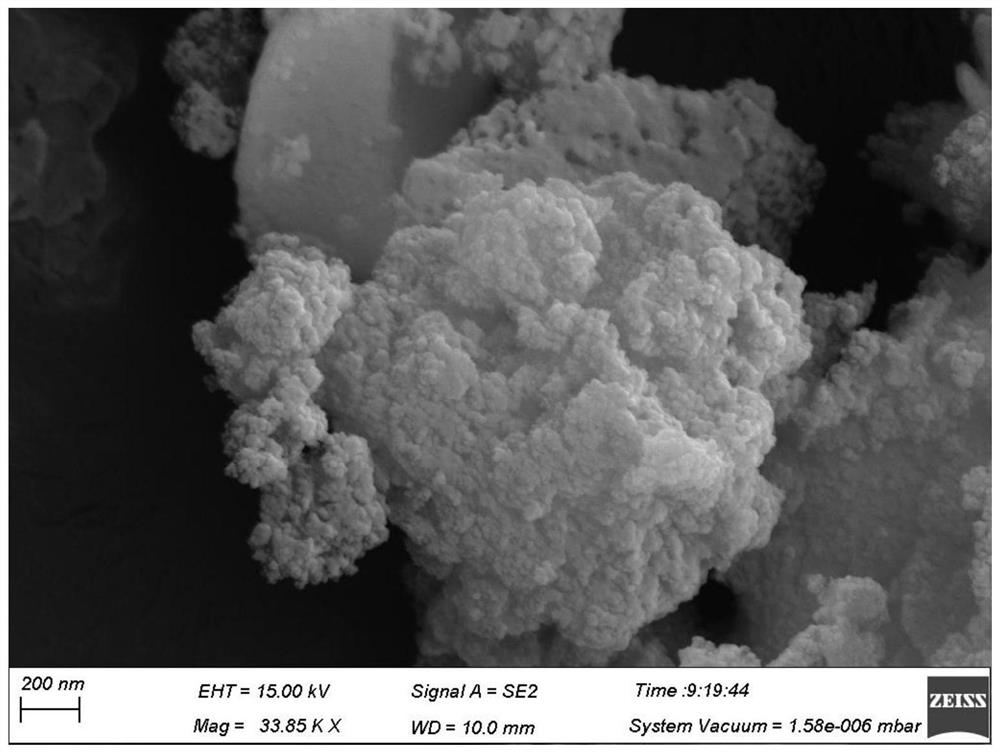

[0034] Example 1: Ni-Mo 2 C / γ-Al 2 O 3 Catalyst preparation and passivation

[0035] (1) Weigh 0.2598g of ammonium paramolybdate, 0.2120g of nickel acetate, and 0.1547g of glucose with an electronic balance, put them in a 10mL small beaker, measure 1.5mL of ammonia water with a measuring cylinder, add it to the beaker, and stir until it is completely dissolved to form a uniform mixture;

[0036] (2) Weigh 0.3g γ-Al 2 O 3 , into a 25mL small beaker. Then drop the blue mixture obtained in step (1) into γ-Al 2 O 3 In the small beaker, stir evenly with a glass rod, then seal the small beaker with plastic wrap, place it in a sonicator for sonication for 20 min, and then let the mixture stand for 12 h. Subsequently, the mixed solution after standing was placed in an oven at 110° C. for drying for 24 h to obtain a tan solid. Grind the obtained solid into fine powder with an agate mortar, put it into a porcelain boat, place it in a tube furnace under the atmosphere of Ar (100...

Embodiment 2

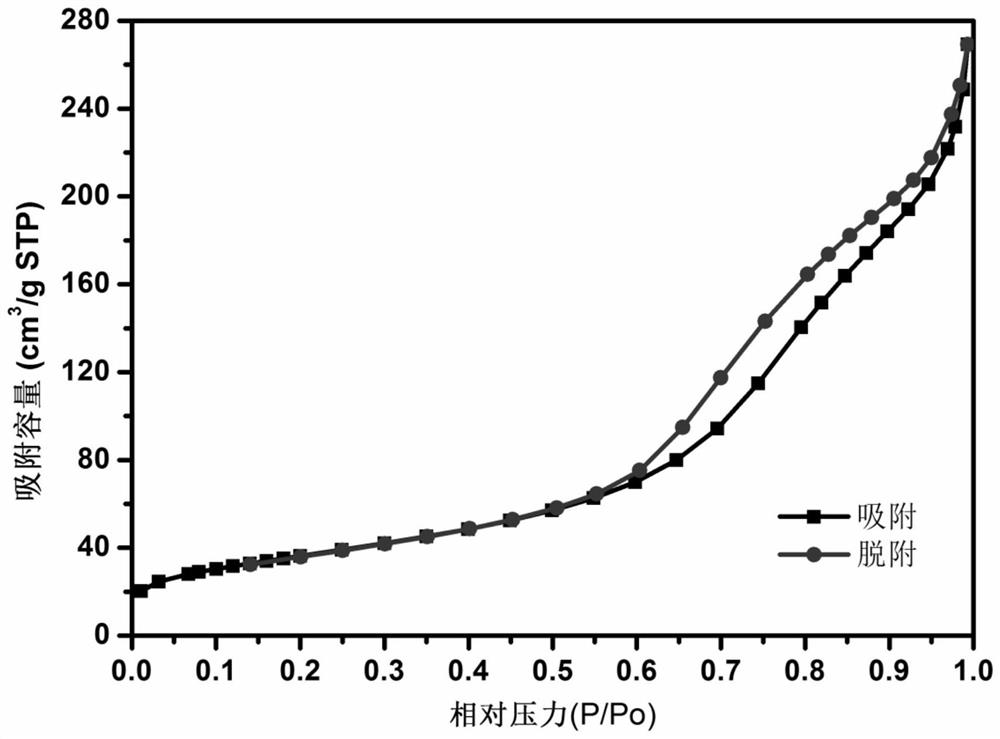

[0040] with N 2 Isothermal adsorption-desorption analysis of specific surface area and pore size distribution. For specific results, see image 3 and 4 . Example 2: Ni-Mo of the present invention 2 C / γ-Al 2 O 3 Performance test as ammonia borane hydrogen production catalyst:

[0041] (1) Preparation of catalyst:

[0042] 10mg of Ni-Mo prepared by the present invention 2 C / γ-Al 2 O 3 The catalyst was placed in a 50mL single-neck round-bottomed flask, 2.5mL of distilled water was measured with a graduated cylinder, and poured into the round-bottom flask containing the catalyst. The round-bottom flask was placed in a sonicator for sonication for 2 min, and then placed at a constant temperature of 30 °C. Ready to use in bathtub.

[0043] (2) Configuration of ammonia borane aqueous solution:

[0044] Accurately weigh 0.2 g of NaOH and place it in a 25 mL beaker, add 2.5 mL of water, ultrasonicate for 30 s to dissolve it completely, then add 45 mg of ammonia borane to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com