Matt glaze powder suitable for electrostatic spraying, and preparation method thereof

A technology of electrostatic spraying and matte glaze, applied in the field of ceramic glazes, can solve problems affecting product quality and yield, easy to block equipment spray guns, poor electrostatic performance, etc., to achieve good electrostatic spraying performance, silky and delicate feel, The effect of uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

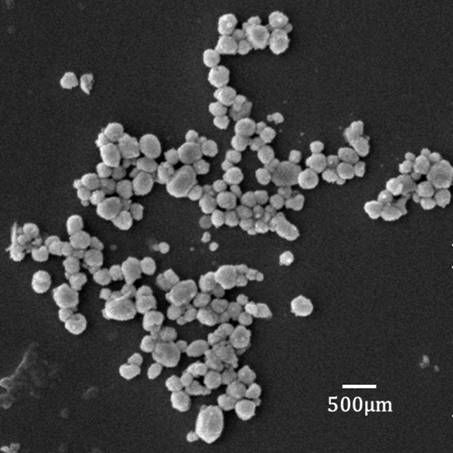

Image

Examples

preparation example Construction

[0054] The present invention also provides a method for preparing matte glaze powder suitable for electrostatic spraying, specifically comprising: 70-75 parts of matte glaze powder raw materials, 15-20 parts of resin, 3-5 parts of curing agent, electrostatic 2~5 parts of additives, 0.1~0.5 parts of wetting agent, 0.1~0.5 parts of leveling agent, 1~3 parts of modified wax powder, grind and mix evenly.

[0055] Preferably, the preparation method of the matte glaze powder suitable for electrostatic spraying mainly comprises the following steps:

[0056] A. Add the resin, curing agent, electrostatic additive, wetting agent, leveling agent, and modified wax powder into the dispersion solvent according to the proportion, and continue stirring until completely dissolved to obtain the first mixed solution;

[0057] B. Add the matte glaze powder raw materials into the first mixed solution according to the proportion, and continue to stir until they are evenly dispersed to obtain the se...

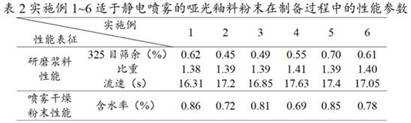

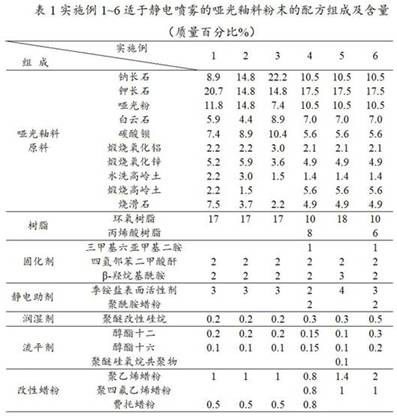

Embodiment 1-6

[0066] The formula of the matte glaze powder that is suitable for electrostatic spraying of embodiment 1~6 consists of:

[0067] Matte glaze powder raw materials, resin, curing agent, static additive, wetting agent, leveling agent, modified wax powder. The matte glaze powder raw materials include: albite, potassium feldspar, matte powder, dolomite, barium carbonate, calcined alumina, calcined zinc oxide, washed kaolin, calcined kaolin, and calcined talc. The resin is one or more of epoxy resin and acrylic resin; the curing agent is one of trimethylhexamethylenediamine, tetrahydrophthalic anhydride, and β-hydroxyalkylamide one or more; the electrostatic auxiliary agent is one or more of quaternary ammonium salt surfactants, polyamide wax powder; the wetting agent is a polyether modified siloxane product; the leveling The agent is one or more of alcohol ester twelve, alcohol ester sixteen, polyether siloxane copolymer; modified wax powder is polyethylene wax powder, polytetrafl...

Embodiment 7

[0075] Firstly, the raw materials are prepared according to the composition and content ratio of Example 1 in Table 1, then all the raw materials are mixed evenly and then ground, and the finished product is obtained after being sieved through a sieve, and the mesh number of the sieve is 120 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com