Online hydrogen purity detection instrument as well as use method and application thereof

A hydrogen purity and detection instrument technology, which is applied in the field of gas detection and optical sensing, can solve the problems of inability to realize online detection, insufficient analysis of impurity content, and long time-consuming gas detection, so as to reduce the influence of external light intensity, save equipment volume, The effect of reducing cross-interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

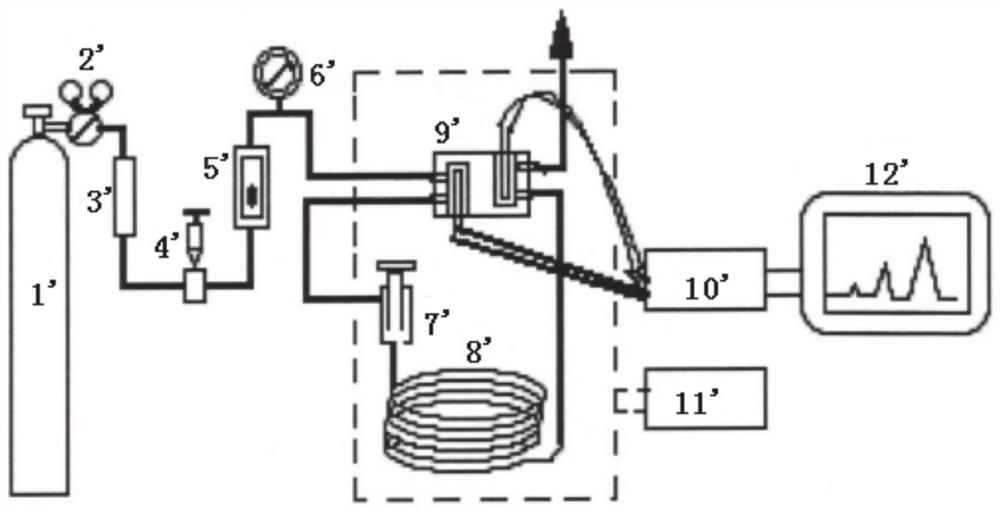

Method used

Image

Examples

Embodiment 1

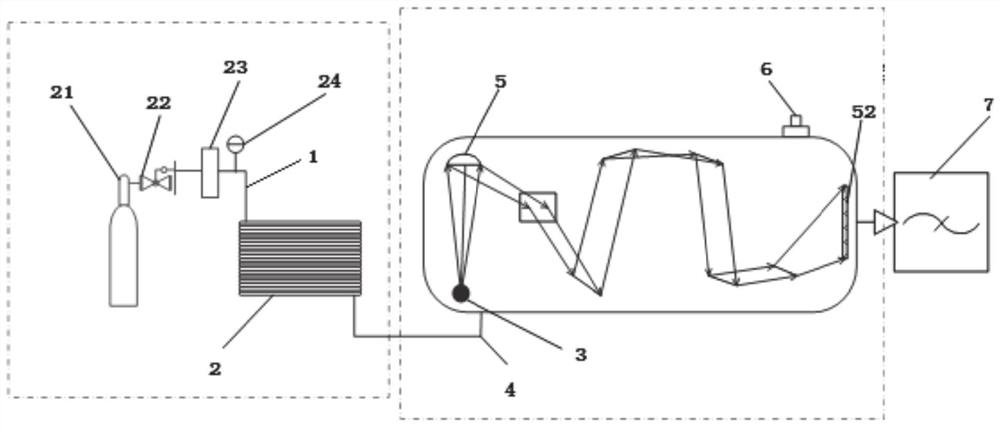

[0062] Such as figure 2 As shown, this embodiment provides an online hydrogen purity detection instrument, including a carrier gas 21, a pressure reducing valve 22, a micro gas chromatography column, a light source 3, a detection gas chamber, a signal processing unit 7 and software modules.

[0063] The micro-gas chromatographic column uses He gas as the carrier gas, and the carrier gas is turned on before the infrared equipment is started to clean the equipment pipeline and gas chamber. The detector is on a single silicon chip, using a 3-meter S-type gas column, and controlling the micro-gas chromatography column to separate the detected gas at a specific time.

[0064] The light source 3 is a tunable semiconductor laser beam, which has the functions of current adjustment and temperature adjustment. The line width of the emitted beam is much smaller than the line width of the single absorption spectrum of the measured gas and the spectral line width of traditional infrared l...

Embodiment 2

[0070] This embodiment provides the method for using the online hydrogen purity detection instrument described in Embodiment 1, which includes the following steps: after the components of the gas to be measured are separated by a gas separation module; the light output by the light source 3 is captured by the optical intensity modulator Amplitude modulation is performed on a specific wavelength range; after the optical path passes through the detection gas chamber, it is collected by an infrared detector and converted into an electrical signal, which is processed by the signal processing unit 7 and repeated detection to obtain the spectral data of each gas at each time period; cooperate with the analysis software to obtain Measure gas composition data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com