Hierarchical structure ZSM-5 molecular sieve containing lanthanum and nickel or/and zinc , and preparation method and application thereof

A ZSM-5, molecular sieve technology, applied in the field of catalytic materials and catalytic chemistry, can solve the problems of increasing gel concentration, difficulty in synthesis, great challenges, etc., and achieves the effects of good test repeatability, simple operation and pollution reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

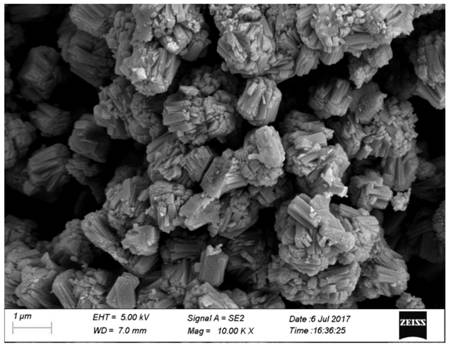

[0063] Example 1: Preparation of ZSM-5 zeolite molecular sieve with zinc and lanthanum hierarchical structure

[0064](1) Treatment of silicon source:

[0065] Take 2g of tetrapropylammonium bromide (0.0075mol, equivalent to 0.06 times that of coarse-pored silica gel) at 25°C, add it to 10g of water (0.556mol, equivalent to 4.444 times that of coarse-pored silica gel), stir evenly, and then add 7.5g Coarse-porous silica gel (0.125 mol), and continue to stir for about 30 minutes to obtain a silicon source solution.

[0066] (2) Treatment of aluminum source, zinc source and lanthanum source:

[0067] At 25°C, add 0.57g of sodium metaaluminate (0.0025mol, equivalent to 0.02 times that of coarse-pored silica gel) into 8.75g of water (0.486mol, equivalent to 3.889 times that of coarse-pored silica gel), stir for 5 minutes and then add 1.47g Zinc nitrate hexahydrate (0.0049mol, equivalent to 0.04 times of coarse-pore silica gel), add 0.57g lanthanum chloride (0.0014mol, equivalent...

Embodiment 2

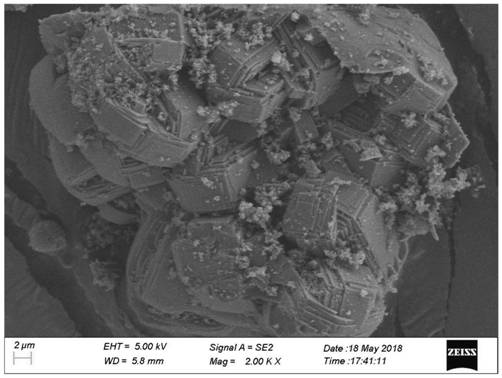

[0072] Embodiment 2: the preparation of nickel, lanthanum multi-level structure ZSM-5 zeolite molecular sieve

[0073] (1) Treatment of silicon source and nickel source:

[0074] At 25°C, take 3g of tetrapropylammonium bromide (0.0113mol, equivalent to 0.09 times of white carbon black) and add it to 10g of water (0.556mol, equivalent to 4.444 times of white carbon black) and stir evenly, then add 7.5g White carbon black (0.125mol) and 0.93g nickel nitrate hexahydrate (0.0032mol, equivalent to 0.026 times of white carbon black), continue stirring for about 30min to obtain silicon source and nickel source solutions, and then aged at 50°C for 10 hours to obtain a uniform solution.

[0075] (2) Treatment of aluminum source and lanthanum source:

[0076] At 25°C, add 1.02g of aluminum isopropoxide (0.0025mol, equivalent to 0.02 times of white carbon black) to 8.75g of water (0.486mol, equivalent to 3.889 times of white carbon black), add 0.29g of lanthanum chloride (0.0007mol, e...

Embodiment 3

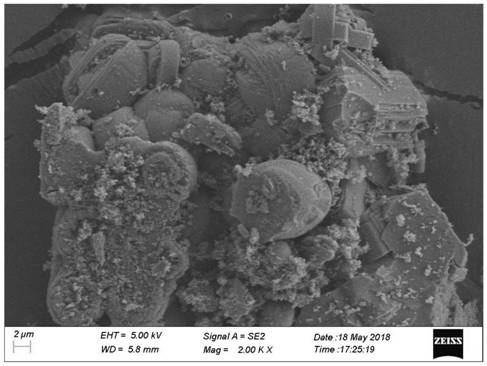

[0081] Example 3: Preparation of ZSM-5 Zeolite Molecular Sieve with Zinc, Nickel, Lanthanum and Low Silicon Hierarchical Structure

[0082] (1) Treatment of silicon source and nickel source:

[0083] Take 3g of tetrapropylammonium bromide (0.0188mol, equivalent to 0.15 times of coarse-pore silica gel) at 30°C and add them to 10g of water (0.556mol, equivalent to 4.444 times of coarse-pore silica gel) and stir evenly, then add 7.5g Coarse porous silica gel (0.125mol) and 0.41g nickel nitrate hexahydrate (0.0014mol, equivalent to 0.011 times of coarse porous silica gel), continue to stir for about 30min to obtain silicon source and nickel source solutions, and then aged at 90°C for 2 hours to obtain a uniform solution.

[0084] (2) Treatment of aluminum source, zinc source and lanthanum source:

[0085] Add 1.02g of aluminum isopropoxide (0.0025mol, equivalent to 0.02 times that of coarse-pored silica gel) at 30°C to 8.75g of water (0.486mol, equivalent to 3.889 times that of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com