Process for producing calcium chloride from iron black filtrate and fluidized bed drying device for production of calcium chloride

A drying device and calcium chloride technology, applied in the direction of drying gas arrangement, drying solid materials, calcium/strontium/barium chloride, etc., can solve the problems of reducing production efficiency, reducing product quality, and exceeding the standard particle size of calcium chloride particles , to achieve the effect of improving drying efficiency, avoiding material agglomeration, and solving difficult-to-handle problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

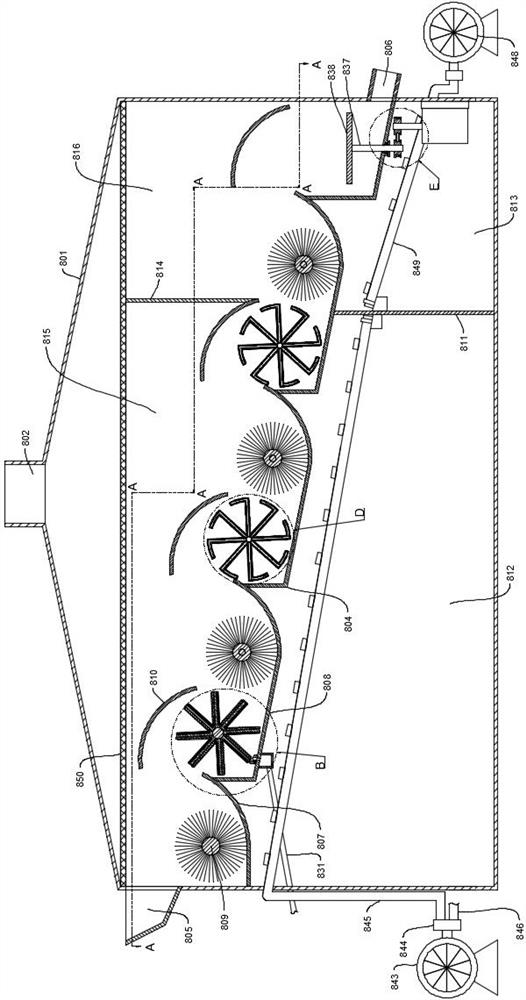

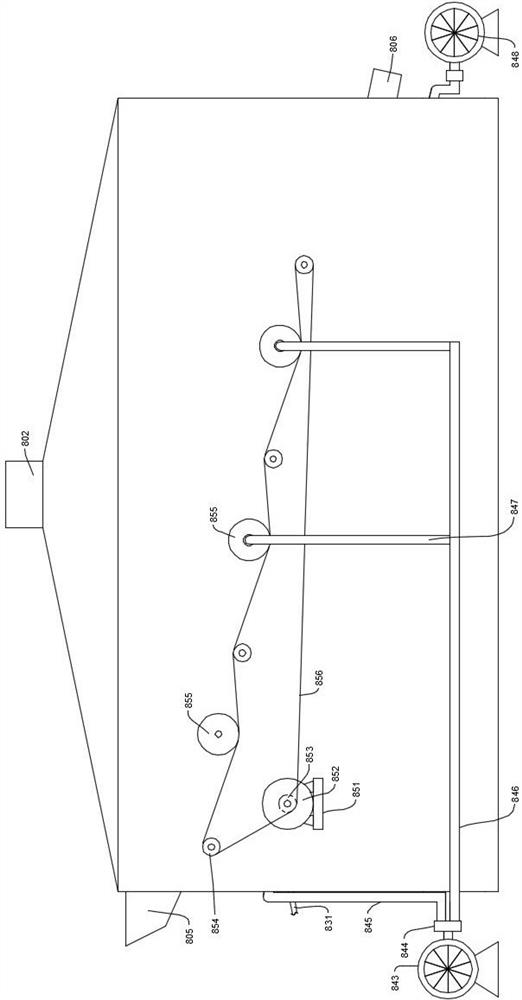

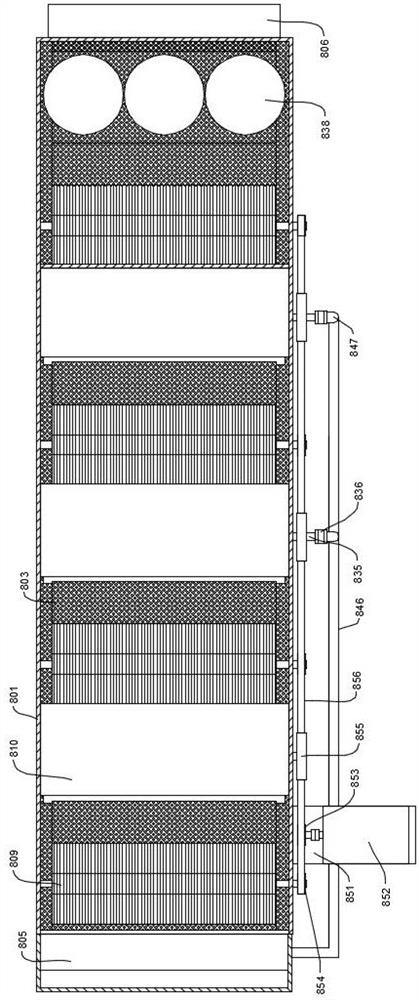

[0046] The present invention will be specifically described below with reference to the drawings. Figure 13 As shown: A iron black filtrate has a calcium chloride process, including the following steps:

[0047] 1, from the iron black filtrate regulating pool 1 to the reactive pool 2 into the A square iron black filtrate;

[0048] 2, adding a B-square concentration of 32% to the primary concentration of 32%, stirring the reaction, and the pH of the liquid in the reaction tank 2 is 8.6, wherein A = 20, b = 6, A: b = 5 : 3.

[0049] 3, add C kg charcoal to the reaction tank 2, stir well, where C = 40, A: C = 1: 4;

[0050] 4. Filtration of the liquid filter 2 is filtered through the plate frame filter machine 4, and the calcium chloride contains iron sludge is filtered, and the liquid is filtered to the secondary treatment of the reaction tank 3;

[0051] 5. Add D kilograms of hydrogen peroxide to the secondary treatment reaction tank 3, and then add E kg activated carbon again, sti...

Embodiment 2

[0072] The present embodiment is substantially the same as that of Example 1, there is a difference in that the black filtrate has a calcium chloride process comprising the steps of:

[0073] 1, from the iron black filtrate regulating pool 1 to the reactive pool 2 into the A square iron black filtrate;

[0074] 2, adding a B-square concentration of 32% to the primary treatment tank 2, stirring the reaction, and the pH of the liquid in the reaction tank 2 is 8.8, wherein A = 20, b = 6.2, A: b = 10 : 3.1.

[0075] 3, add C kg charcoal to the reaction tank 2, stir well, where C = 40, A: C = 1: 4;

[0076] 4. Filtration of the liquid filter 2 is filtered through the plate frame filter machine 4, and the calcium chloride contains iron sludge is filtered, and the liquid is filtered to the secondary treatment of the reaction tank 3;

[0077] 5. Add D kilograms of hydrogen peroxide to the secondary treatment reaction tank 3, and then add E kg activated carbon again, stir well, wherein D =...

Embodiment 3

[0082] The present embodiment is substantially the same as that of Example 1, there is a difference in that the black filtrate has a calcium chloride process comprising the steps of:

[0083] 1, from the iron black filtrate regulating pool 1 to the reactive pool 2 into the A square iron black filtrate;

[0084] 2, adding a B-square concentration of 32% to a primary concentration of 32% to a stirring reaction, and the pH of the liquid in the reactive tank 2 is 8.9, wherein A = 20, B = 6.4, A: b = 10 : 3.2.

[0085] 3, add C kg charcoal to the reaction tank 2, stir well, where C = 40, A: C = 1: 4;

[0086] 4. Filtration of the liquid filter 2 is filtered through the plate frame filter machine 4, and the calcium chloride contains iron sludge is filtered, and the liquid is filtered to the secondary treatment of the reaction tank 3;

[0087] 5. Add D kilograms of hydrogen peroxide to the secondary treatment reaction tank 3, and then add E kg activated carbon again, stir well, wherein D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com