Method for preparing high-performance beryllium-copper alloy through mechanical vibration treatment and high-performance beryllium-copper alloy

A technology of mechanical vibration and beryllium copper alloy, which is applied in the field of metal material processing, can solve the problems of difficulty in effectively improving the performance of beryllium copper alloy, long solid solution time, and coarsening, so as to be suitable for large-scale production and avoid grain coarsening , the effect of uniform dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The beryllium-copper alloy suitable for the preparation method provided by the invention is preferably a beryllium-copper alloy comprising the following mass percentage components: Co 0.6-1.2%, Ni 1.5-2.0%, Be 0.4-0.7% and the remainder of Cu; more preferably It is: Co 0.7-1.0%, Ni 1.8-2.0%, Be 0.45-0.65%, and the balance Cu.

[0028] In the invention, alloy raw materials are smelted to obtain a melt.

[0029] In the present invention, the alloy raw materials preferably include 0.6-1.2% of pure cobalt sheet, 1.5-2.0% of pure nickel wire, 11.6%-20.3% of beryllium-copper master alloy and the balance of electrolytic Copper; more preferably including 0.7-1.2% of pure cobalt sheet, 1.5-2.0% of pure nickel wire, 13%-18% of beryllium-copper master alloy and the balance of electrolytic copper. The present invention can make the ratio of each element in the beryllium-copper alloy more conducive to improving the performance of the beryllium-copper alloy by regulating the additio...

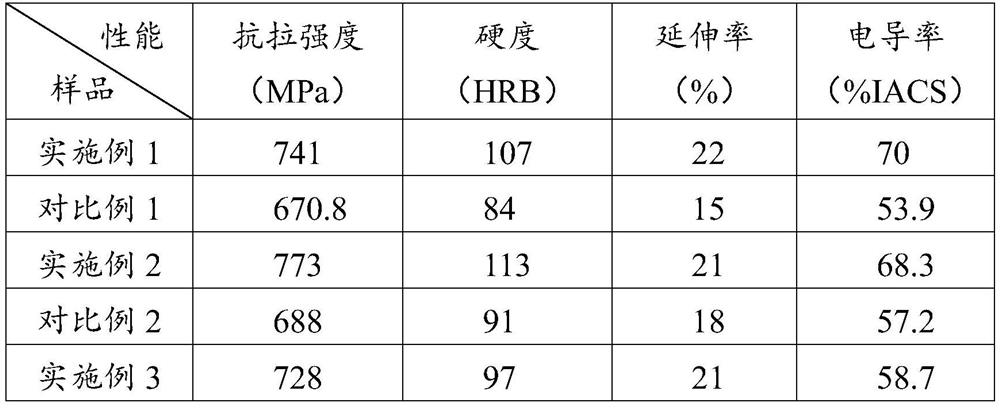

Embodiment 1

[0053] The method for preparing high-performance beryllium-copper alloy by mechanical vibration treatment in this embodiment is specifically as follows:

[0054] (1) In terms of mass percentage, add 83% electrolytic copper (99.99% purity) into the crucible in the smelting furnace, melt it completely at 1300°C, and then add 0.8 % pure cobalt sheet (purity is 99.99%) and 1.7% pure nickel wire (purity is 99.99%), then add 14.5% Cu-3.8Be master alloy, smelting for 60s, continuously add charcoal powder in the smelting process to prevent Oxidation, to obtain a melt;

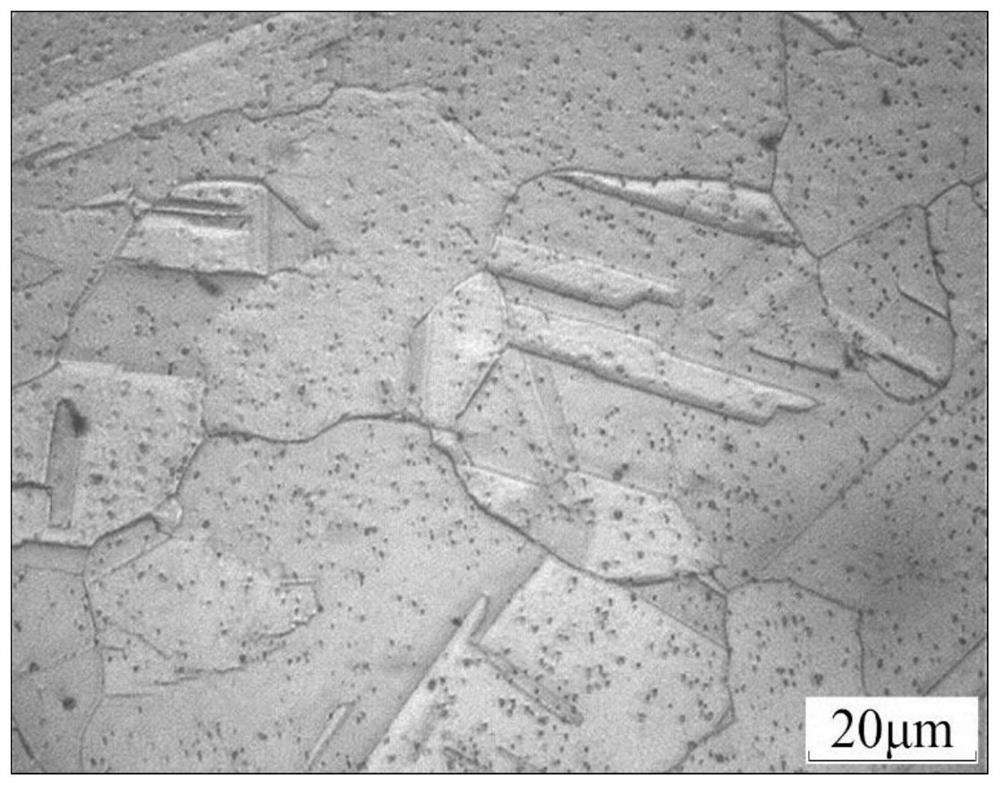

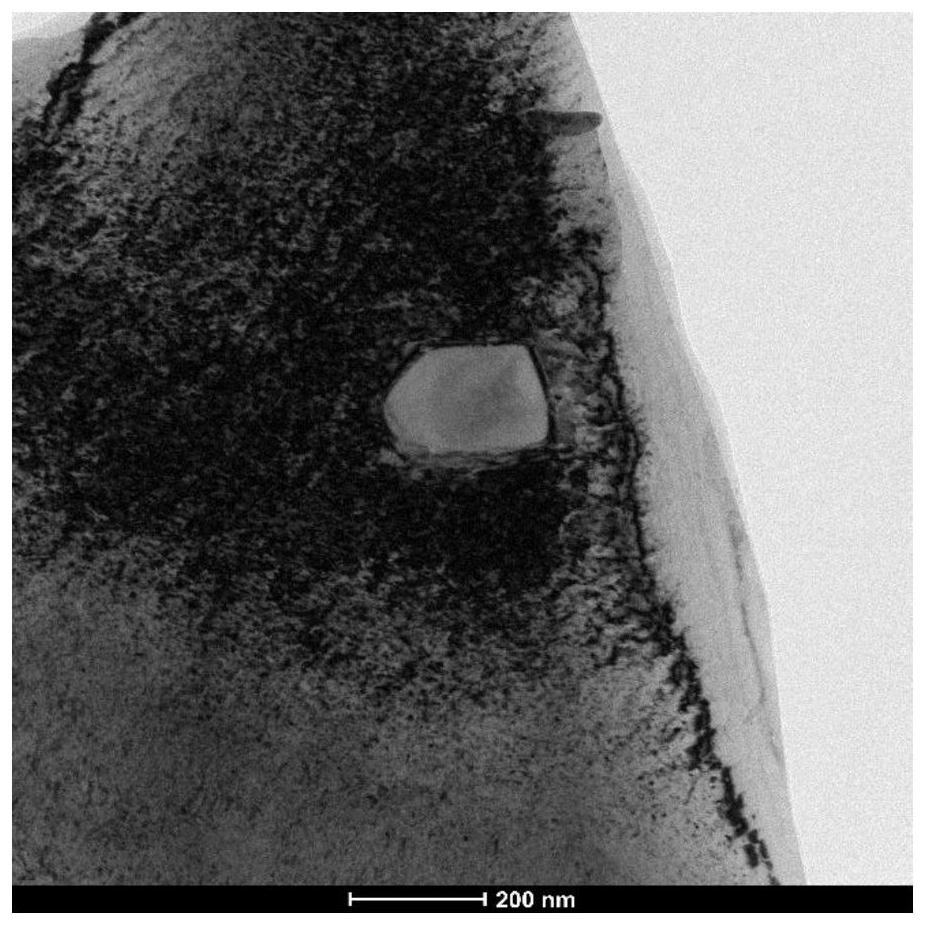

[0055] (2) Adjust the temperature of the melt obtained in the step (1) to 1250°C for casting. During the casting, the melt is tilted and paused for 1 second, so that the low-density charcoal powder floats on the surface of the melt and the melt naturally sinks close to the gate. Finally, cast the pure melt into a stainless steel mold under mechanical vibration, and keep the mechanical vibration until the melt is compl...

Embodiment 2

[0061] The method for preparing high-performance beryllium-copper alloy by mechanical vibration treatment in this embodiment is specifically as follows:

[0062] (1) In terms of mass percentage, add 80.1% electrolytic copper (purity: 99.99%) into the crucible in the smelting furnace, melt it completely at 1300°C, and then add 0.8 % pure cobalt sheet (purity is 99.99%) and 1.7% pure nickel wire (purity is 99.99%), then add 17.4% Cu-3.8Be master alloy, smelting for 60s, continuously add charcoal powder in the smelting process to prevent Oxidation, to obtain a melt;

[0063] (2) Adjust the temperature of the melt obtained in the step (1) to 1250°C for casting. During casting, the melt is tilted and paused for 1 second, so that the low-density charcoal powder floats on the surface of the melt and the melt naturally sinks close to the pouring After the mouth, the pure melt is cast into a stainless steel mold under mechanical vibration, and the mechanical vibration is maintained un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com