Platinum-based catalyst taking hexagonal boron-carbon-nitrogen as carrier and preparation method of platinum-based catalyst

A platinum-based catalyst and boron carbon nitrogen technology, which is applied in the field of low-carbon alkane dehydrogenation catalyst preparation, can solve the problems of catalyst coking, sintering and high reaction temperature, and achieve the effect of high activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0032] Preparation of catalyst of the present invention and performance evaluation of propane dehydrogenation

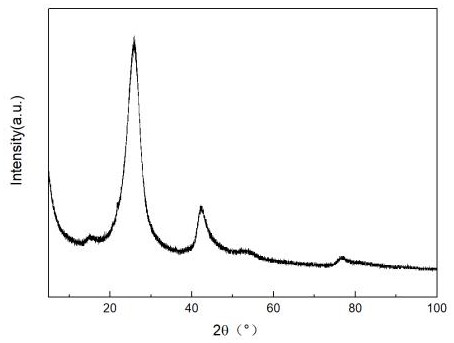

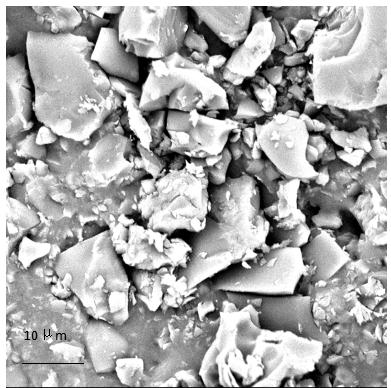

[0033] (1) Preparation of catalyst

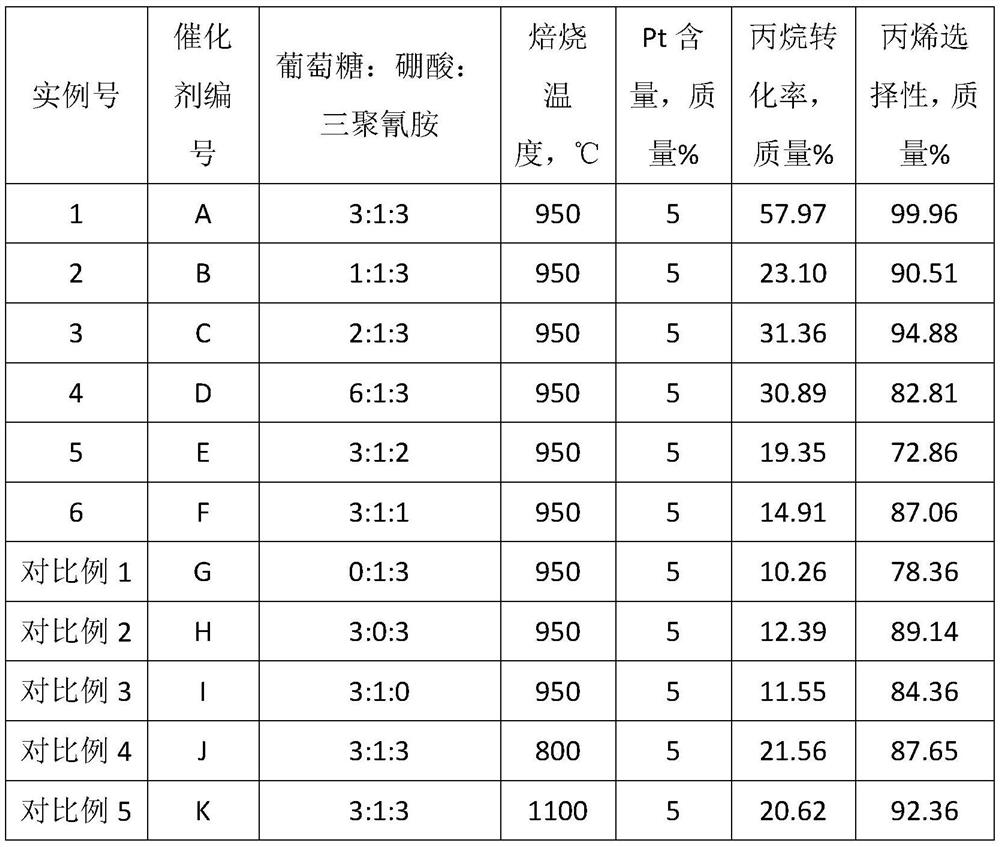

[0034]1 g of boric acid, 3 g of melamine and 3 g of glucose were thoroughly ground with an agate mortar. The mixed precursors are then put into a horizontal tube furnace. Before heating, exhaust all the oxygen in the tube for about 30 minutes, calcinate at 950°C for 6 hours, and wash the obtained product with 0.1M HCl in hot water to obtain a hexagonal boron carbon nitrogen carrier. Take 0.5 g of hexagonal borocarbon nitrogen carrier, put it into 5 mL of chloroplatinic acid solution with a Pt content of 5 mg / mL and 5 mL of ethanol. Stir at 25°C for 3h, sonicate for 3h, stir for another 3h, completely evaporate the ethanol in the system to dryness at 80°C, and then dry at 80°C overnight. put it in N 2 Calcined at 500°C for 2h in the atmosphere to obtain catalyst A. The content of platinum element in catalyst A, the ratio of bo...

example 2

[0038] Prepare catalyst and carry out propane dehydrogenation reaction by the method for example 1, difference is (1) the quality of glucose in the step is 1g, the platinum element content in the catalyst B of making, used boric acid, melamine and glucose ratio and propane dehydrogenation The reaction results are shown in Table 1. The results of the 10-hour reaction are shown in Table 3.

example 3

[0040] Prepare catalyst by the method for example 1 and carry out propane dehydrogenation reaction, difference is (1) the quality of glucose in the step is 2g, the platinum element content in the catalyst C of making, used boric acid, melamine and glucose ratio and propane dehydrogenation The reaction results are shown in Table 1. The results of the 10-hour reaction are shown in Table 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com