Two-dimensional layered composite film and preparation method and application thereof

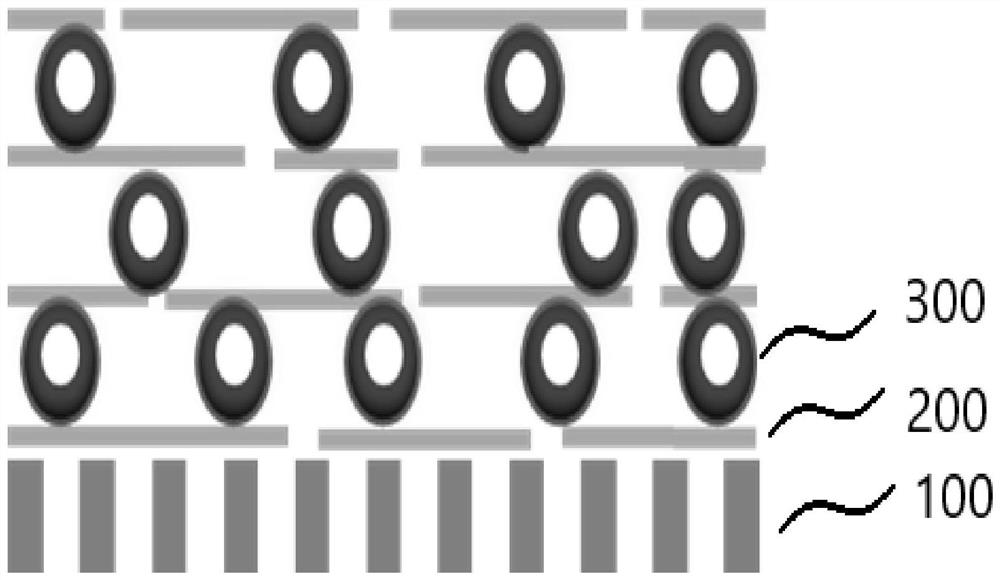

A two-dimensional layered, composite membrane technology, applied in the field of separation membranes, can solve the problems of reduced layered passage, attenuation of water flux, blockage of membrane pores, etc., to enhance strength and stability, reduce energy consumption, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

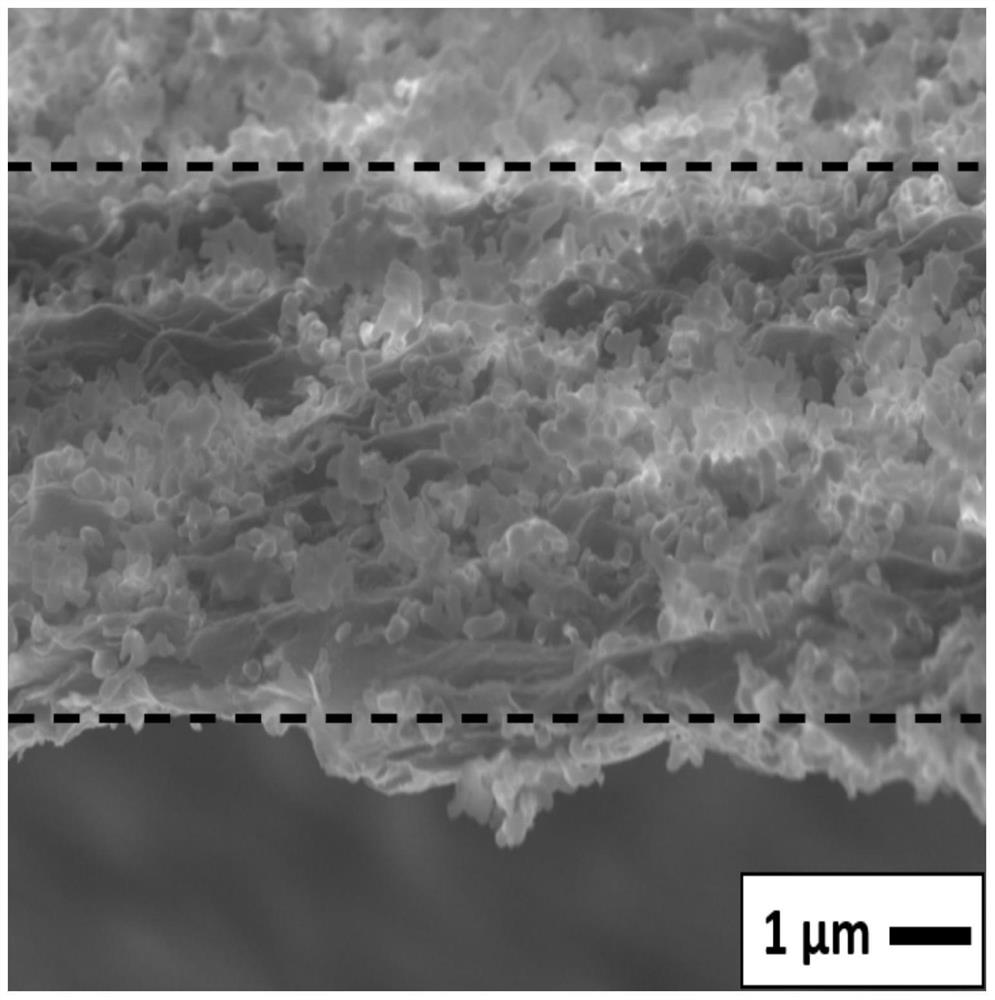

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, a two-dimensional layered composite film is prepared, and the specific process is as follows:

[0048] (1) Etching the two-dimensional nanosheets with an etching solution of concentrated hydrochloric acid and lithium fluoride, ultrasonically dispersing, and centrifuging to obtain a solution with a concentration of 100 ppm.

[0049] (2) Mix the nanospheres with deionized water to prepare a solution with a concentration of 100ppm.

[0050] (3) The polymer substance is dissolved in N-methylpyrrolidone to obtain a base film precursor solution with a mass ratio of 15wt%, and the precursor solution is placed on a clean glass plate, and after coating the film with a coating knife with a thickness of 150 microns , to form a uniform liquid film, put the glass plate together in room temperature water immediately, let it stand for 30 minutes, and obtain a vertical strip-shaped microporous base film with a pore size of 0.45 microns after solidification.

[0051...

Embodiment 2

[0054] In this embodiment, a two-dimensional layered composite film is prepared, and the specific process is as follows:

[0055] (1) Titanium carbide was etched with an etching solution of concentrated hydrochloric acid and lithium fluoride, ultrasonically dispersed, and centrifuged to obtain an MXene solution with a concentration of 100 ppm.

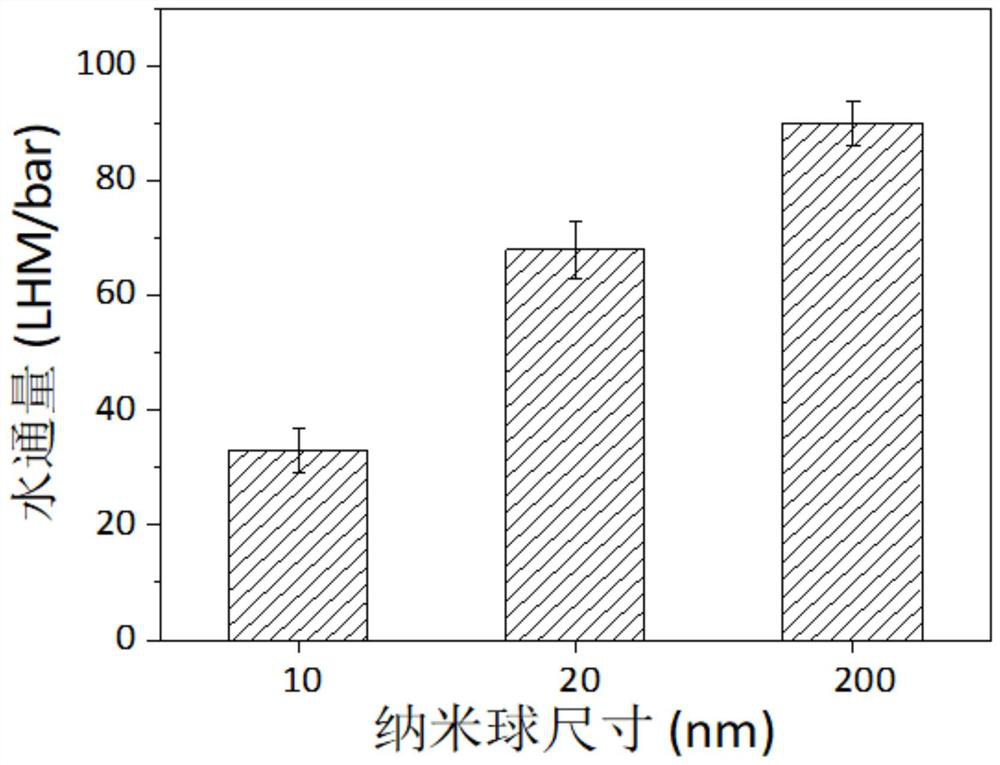

[0056] (2) the size is 200nm nanometer Al 2 o 3 Mix with deionized water to prepare a solution with a concentration of 100ppm.

[0057] (3) Dissolve the polymer substance (powdered polyvinylidene fluoride) in N-methylpyrrolidone to obtain a basement film precursor solution with a mass ratio of 15 wt%, place the precursor solution on a clean glass plate, and use a 150 micron knife edge After coating the film with a thick coating knife, a uniform liquid film is formed, and the glass plate is immediately placed in room temperature water for 30 minutes. After curing, a vertical strip-shaped microporous base film with a pore size of 0.45 ...

Embodiment 3

[0060] In this embodiment, a two-dimensional layered composite film is prepared, and the specific process is as follows:

[0061] (1) Dilute GO (graphene oxide) with deionized water and ultrasonically disperse to obtain a GO solution with a concentration of 100ppm.

[0062] (2) the size is 200nm nanometer Al 2 o 3 Mix with deionized water to prepare a 100ppm solution.

[0063] (3) Dissolve powdered polyvinylidene fluoride in N-methylpyrrolidone at room temperature to obtain a basement film precursor solution with a mass ratio of 15 wt%, and place the precursor solution on a clean glass plate by using a 150-micron knife edge After coating the film with a thick coating knife, a uniform liquid film is formed, and the glass plate is immediately placed in room temperature water for 30 minutes. After curing, a vertical strip-shaped microporous base film with a pore size of 0.45 microns is obtained.

[0064] (4) Combine the GO solution obtained in steps (1) and (2) with nano-Al 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com