Cyanide removal agent and preparation method thereof

A kaolin and modified technology, which is applied in chemical instruments and methods, water/sludge/sewage treatment, water pollutants, etc., can solve problems such as high cost of treatment methods, shortened settling time, and secondary pollution of the environment, achieving Reduce the cost of water quality treatment, accelerate the speed of sedimentation, and have good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

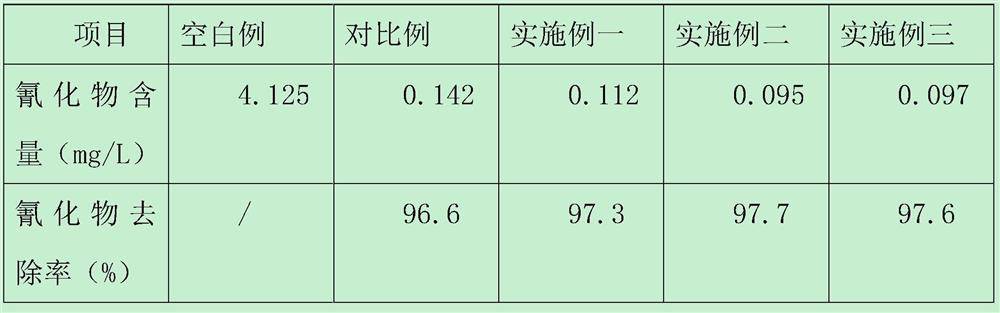

Embodiment 1

[0028] An embodiment of the present invention provides a cyanide removal agent, which includes the following raw materials in parts by weight: 40 parts of modified kaolin, 20 parts of slaked lime, 4 parts of copper sulfate, 6 parts of sodium sulfite, 10 parts of polyaluminum chloride, and 15 parts of bamboo charcoal 2 parts, silicon dioxide 2 parts, sodium alginate 12 parts, ferrous sulfate 10 parts, sodium lignosulfonate 3 parts, carbide slag 5 parts.

[0029] A kind of preparation method of cyanogen removal agent, this preparation method comprises the following steps:

[0030] S1, prepare modified kaolin, its preparation method is as follows:

[0031] 1) Weighing kaolin, sending kaolin into a roasting furnace for roasting, the kaolin roasting temperature is 600-900°C, and the roasting time is 2-5 hours, adding zinc powder, aluminum powder and hydrochloric acid solution to the high-temperature roasted kaolin, Place the above mixture in a sealed container and stir;

[0032] ...

Embodiment 2

[0037] An embodiment of the present invention provides a cyanide removal agent, which includes the following raw materials in parts by weight: 50 parts of modified kaolin, 25 parts of slaked lime, 5 parts of copper sulfate, 8 parts of sodium sulfite, 15 parts of polyaluminum chloride, and 20 parts of bamboo charcoal parts, 3 parts of silicon dioxide, 15 parts of sodium alginate, 15 parts of ferrous sulfate, 4 parts of sodium lignosulfonate, and 6 parts of carbide slag.

[0038] A kind of preparation method of cyanogen removal agent, this preparation method comprises the following steps:

[0039] S1, prepare modified kaolin, its preparation method is as follows:

[0040] 1) Weighing kaolin, sending kaolin into a roasting furnace for roasting, the kaolin roasting temperature is 600-900°C, and the roasting time is 2-5 hours, adding zinc powder, aluminum powder and hydrochloric acid solution to the high-temperature roasted kaolin, Place the above mixture in a sealed container and...

Embodiment 3

[0046] An embodiment of the present invention provides a cyanide removal agent, which includes the following raw materials in parts by weight: 60 parts of modified kaolin, 30 parts of slaked lime, 6 parts of copper sulfate, 10 parts of sodium sulfite, 20 parts of polyaluminum chloride, and 25 parts of bamboo charcoal 4 parts, silicon dioxide 4 parts, sodium alginate 18 parts, ferrous sulfate 20 parts, sodium lignosulfonate 5 parts, carbide slag 7 parts.

[0047] A kind of preparation method of cyanogen removal agent, this preparation method comprises the following steps:

[0048] S1, prepare modified kaolin, its preparation method is as follows:

[0049] 1) Weighing kaolin, sending kaolin into a roasting furnace for roasting, the kaolin roasting temperature is 600-900°C, and the roasting time is 2-5 hours, adding zinc powder, aluminum powder and hydrochloric acid solution to the high-temperature roasted kaolin, Place the above mixture in a sealed container and stir;

[0050]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com