Method for promoting Fenton oxidation, system for promoting Fenton oxidation reaction and application

A Fenton oxidation and reaction system technology, applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc. , the effect of improving the reaction speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

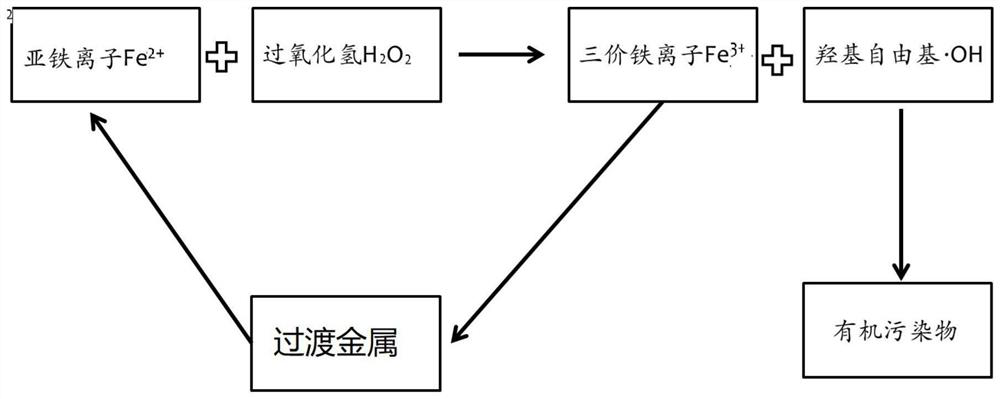

AI Technical Summary

Problems solved by technology

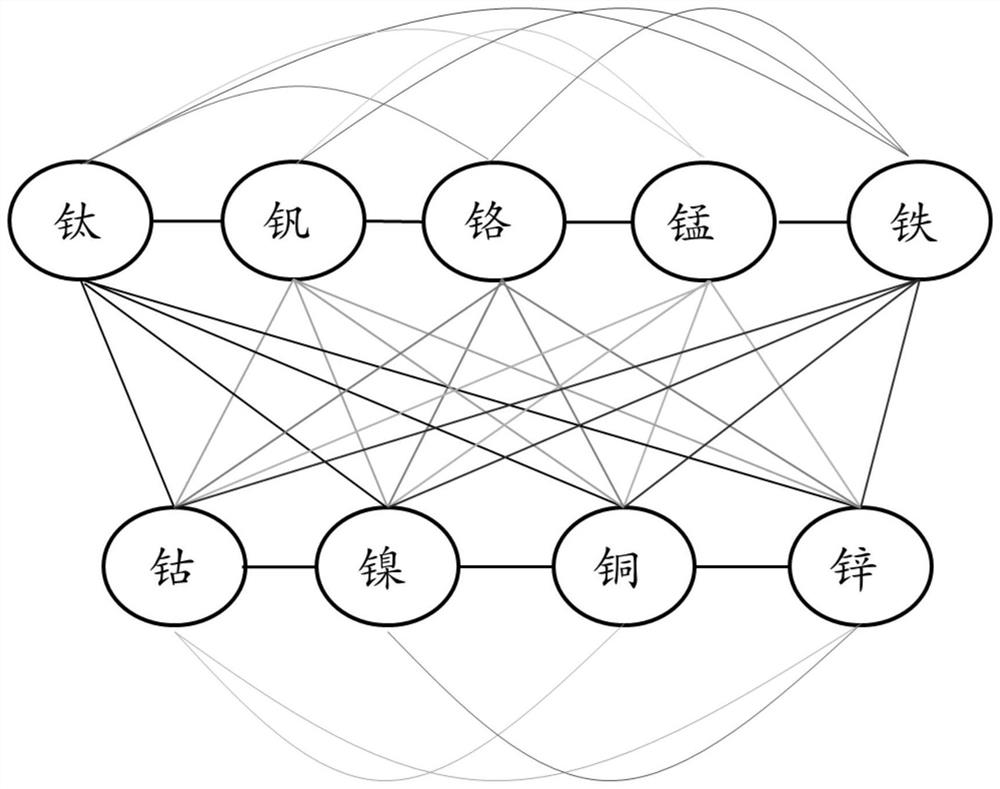

Method used

Image

Examples

Embodiment 1

[0042] In a coking plant CODcr = 325mg\L coking waste water was added a suitable proportion of Fenton reagent (the molar ratio of ferrous ion and hydrogen peroxide was 1:8), the pH value was controlled at 3.5, and it was divided into 8 identical groups Groups 1 to 4 introduce a single substance of one of the transition metals to promote the oxidation of Fenton’s agent, taking simple iron as an example; Groups 5 to 8 do not introduce any simple substance of transition metals, transition metal alloys, transition metal compounds, etc., The reaction time is all controlled at a certain value between 30 minutes and 180 minutes. After the reaction was completed, the COD value was tested by the national standard method. The COD values of the 1 to 4 groups were: 27.8mg\L, 23.1mg\L, 21.7mg\L and 24.8mg\L. The COD values of groups 5 to 8 were 117.3mg\L, 125.4mg\L, 120.1mg\L and 127.5mg\L respectively, and the wastewater was degraded stably from COD≥300mg\L to below 30mg\L. The avera...

Embodiment 2

[0044] Taking copper and iron alloys as an example, the two can be alloyed in any proportion. Taking the alloy made at a ratio of 1:20 as an example, an appropriate ratio of Fenton’s agent (the molar ratio of ferrous ion and hydrogen peroxide is 1:8) was added to the coking wastewater of a coking plant with CODcr=325mg\L, and the pH The value is controlled at 3.5, divided into 4 identical groups, and copper-iron 1:20 alloy is added to promote the oxidation of Fenton's agent, and the reaction time is controlled between 30 minutes and 180 minutes. After the reaction was completed, the COD value was tested by the national standard method. The COD values of the four groups were: 24.5mg\L, 22.5mg\L, 25.3mg\L and 22.6mg\L. All from COD ≥ 300mg\L to 30mg\L or less. The consumption of a simple substance of one of the transition metals averaged 0.049% per hour.

Embodiment 3

[0046] Taking elemental copper as an example, add a suitable proportion of Fenton's reagent (the molar ratio of ferrous ion to hydrogen peroxide is 1:8, the pH value is controlled at 3.5, divided into complete For the same 4 groups, elemental copper was added to promote the oxidation of Fenton’s agent, and the reaction time was controlled between 30 minutes and 180 minutes. After the reaction was completed, the COD value was tested by the national standard method, and the COD values of the 4 groups were: 21.9 mg\L, 26.7mg\L, 22.3mg\L and 19.8mg\L. They all degrade stably from COD ≥ 300mg\L to below 30mg\L. The average consumption of the transition metal is 0.027% per hour.

[0047] From the above description, it can be seen that the above-mentioned embodiments of the present invention have achieved the following technical effects:

[0048] At present, domestic coking wastewater treatment generally adopts biochemical combined advanced treatment process, including the use of F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com