Treatment method of nitrochlorobenzene wastewater

A technology for nitrochlorobenzene and a treatment method, which is applied in water/sewage treatment, special compound water treatment, biological water/sewage treatment, etc., can solve the problems of poor process continuity, high cost of hazardous waste treatment, and low sodium sulfate content. , to achieve the effect of reducing evaporation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

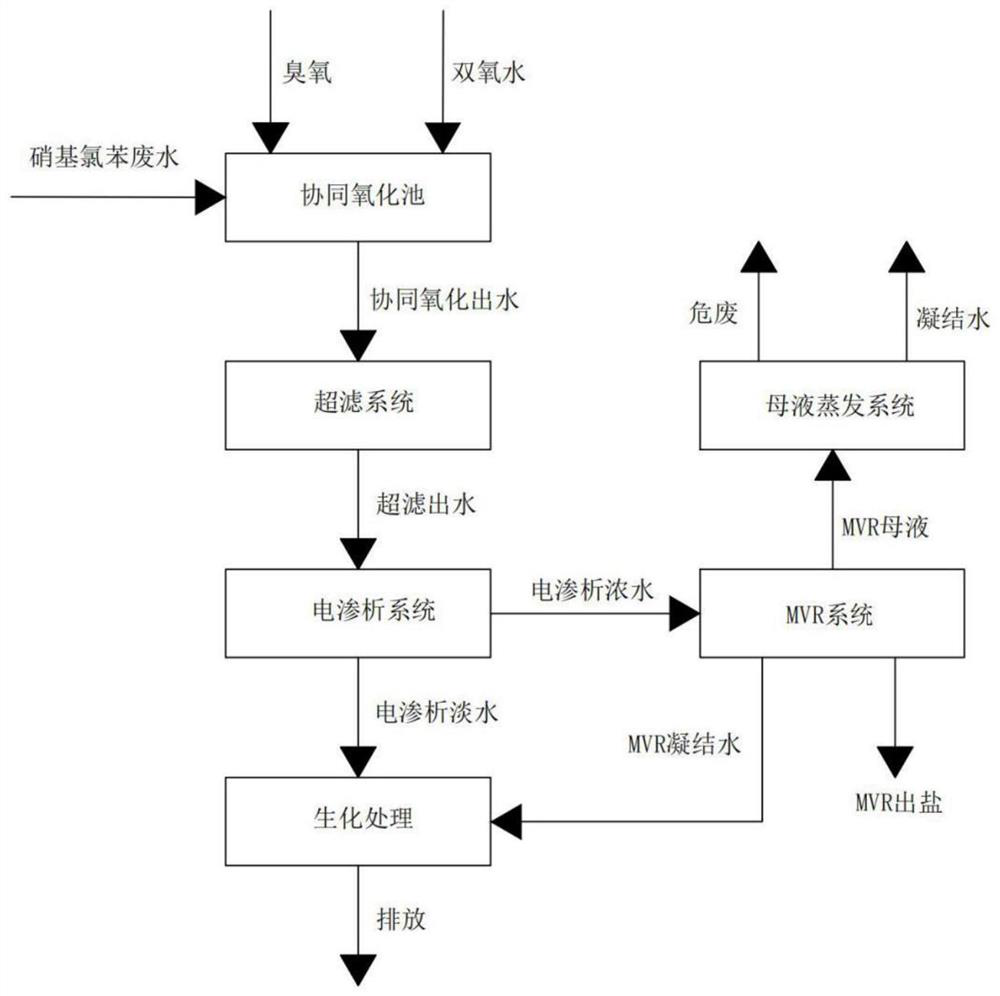

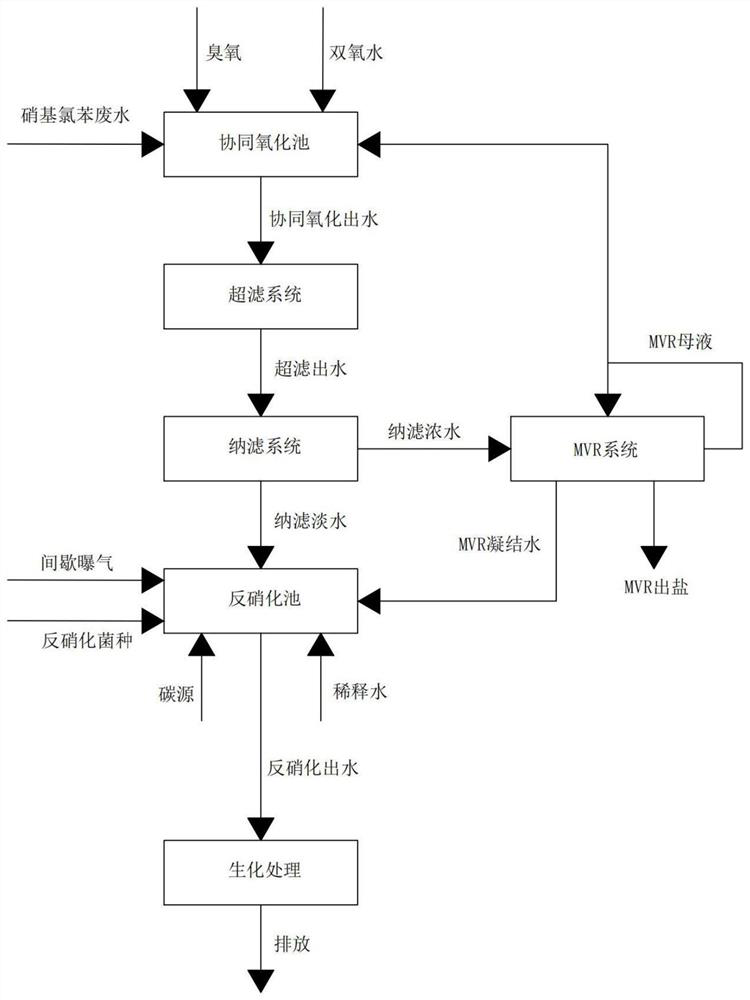

[0028] Such as figure 2 Shown, the invention provides a kind of treatment method of nitrochlorobenzene waste water, comprises the following steps:

[0029] S1: Continuously put nitrochlorobenzene wastewater into the synergistic oxidation tank, and at the same time pass ozone into the wastewater, and add hydrogen peroxide to obtain synergistic oxidation effluent;

[0030] S2: Introduce the synergistic oxidation effluent into the sludge tank for sedimentation to obtain clear wastewater and a small amount of sludge;

[0031] S3: Introduce the clean wastewater into the ultrafiltration system, filter out solid insolubles, and obtain ultrafiltration effluent;

[0032] S4: introduce the ultrafiltration effluent into the nanofiltration system to obtain nanofiltration concentrated water and nanofiltration fresh water;

[0033] S5: Introduce the concentrated nanofiltration water into the MVR system for evaporation to obtain MVR salt, MVR condensate and MVR mother liquor;

[0034] S6...

Embodiment 2

[0044] Different from Example 1, in Example 2, the ozone consumption is 32kg / h, the hydrogen peroxide consumption is 40kg / h, calculated with COD:TN=6, and the methanol consumption is 42.7kg / h.

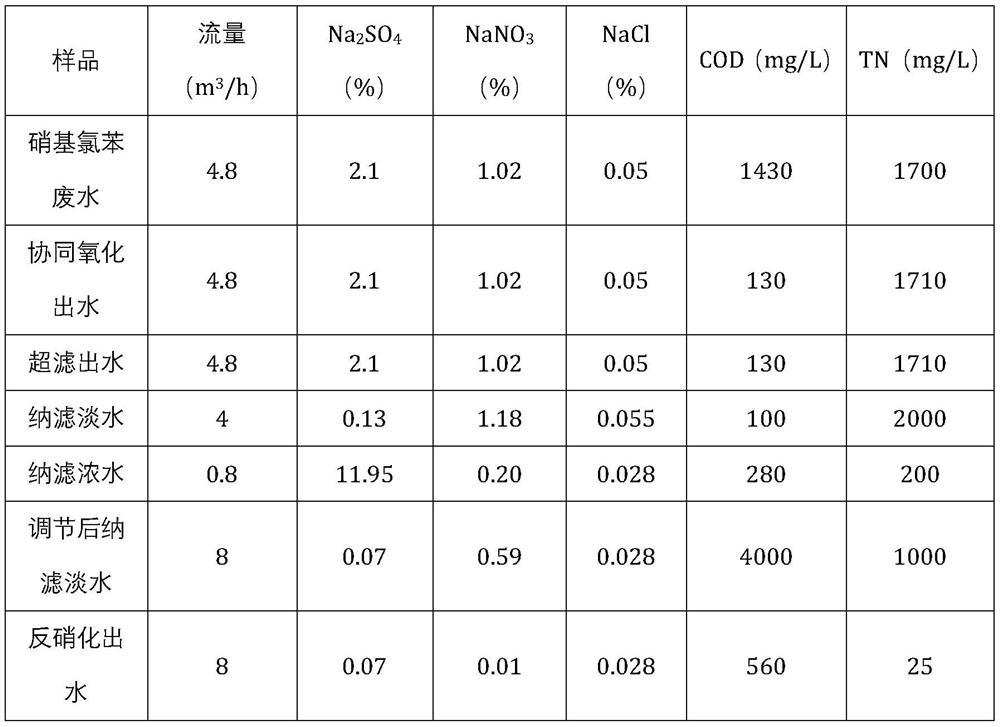

[0045] The relevant data of wastewater treatment are shown in Table 2:

[0046] Table 2

[0047]

Embodiment 3

[0049] Different from Example 1, in Example 3, the ozone consumption is 24kg / h, the hydrogen peroxide consumption is 48kg / h, the carbon source adopts glucose, and the consumption is calculated with COD:TN=6, and the glucose consumption is 48.6kg / h.

[0050] The relevant data of wastewater treatment are shown in Table 3:

[0051] table 3

[0052]

[0053]

[0054] To sum up the above data can be obtained, a kind of treatment method of nitrochlorobenzene wastewater of the present invention can open the benzene ring in the wastewater through the synergistic oxidation of ozone and hydrogen peroxide, which is beneficial to biochemical treatment, and the solid insoluble matter can be filtered by the ultrafiltration system. to prevent clogging of the nanofiltration system; through the nanofiltration membrane of the nanofiltration system, the wastewater is divided into nanofiltration concentrated water and nanofiltration fresh water. The filtration rate of sodium sulfate is as h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com