Preparation method of two-dimensional transition metal chalcogenide

A technology of transition metal chalcogenides and transition metals, which is applied in the preparation of two-dimensional transition metal chalcogenides with large size, high quality and uniform layers, and the preparation of two-dimensional transition metal chalcogenides, which can solve the problem of small size and two-dimensional TMDs Problems such as uncontrollable number of material layers and poor product quality achieve the effects of reducing preparation costs, easy large-area preparation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

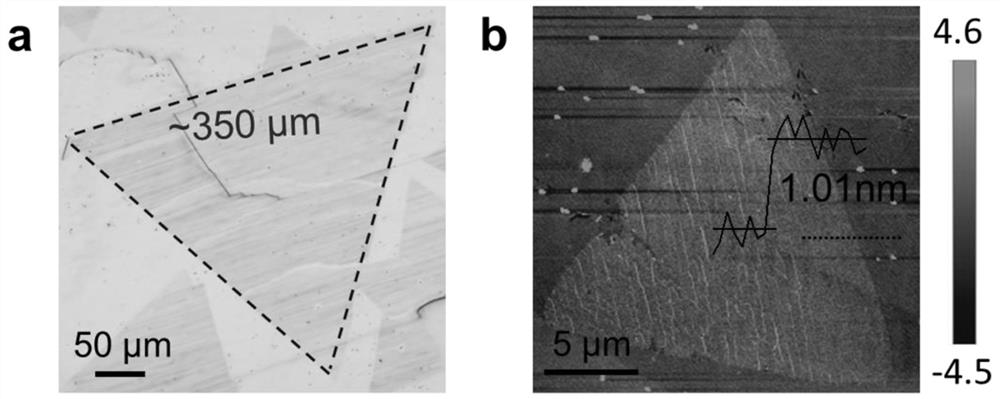

[0029] 1. Preparation of uniform monolayer molybdenum diselenide single crystal

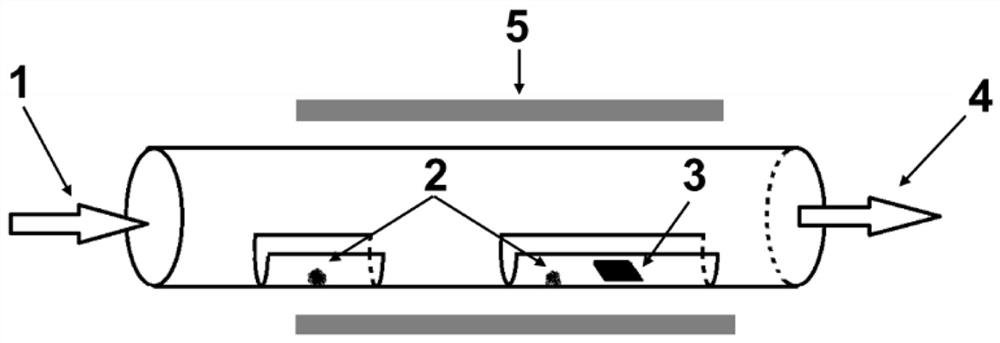

[0030] Such as figure 1 As shown, a large-size, high-quality, uniform single-layer two-dimensional molybdenum diselenide single crystal is grown in a horizontal reactor. The two ends of the horizontal reactor are respectively provided with a gas inlet 1 and a gas outlet 4. The gold substrate is placed in a horizontal reactor. In the high-temperature zone of the furnace, gold foil (10 mm × 10 mm × 100 microns, with a purity of 99.99 wt%) is placed in the central area of a horizontal reaction furnace (the diameter of the furnace tube is 25 mm, and the length of the reaction zone is 5 cm); molybdenum trioxide powder (purity 99.999%) 21.3 mg was placed at 3 cm from the front of the gold foil; 120 mg of selenium powder (purity 99.99%) was placed at 350°C in a horizontal reactor, and the reactor was heated to 900°C in an argon atmosphere ( The flow rate of argon gas is 100 ml / min, and the average te...

Embodiment 2

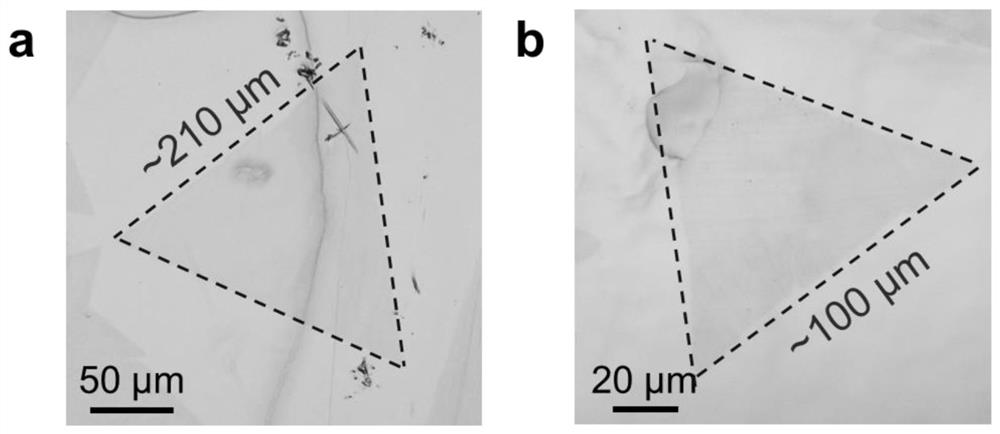

[0035] 1. Preparation of uniform monolayer molybdenum diselenide single crystal

[0036] Such as figure 1 As shown, a large-size, high-quality, uniform single-layer two-dimensional molybdenum diselenide single crystal is grown in a horizontal reactor. The two ends of the horizontal reactor are respectively provided with a gas inlet 1 and a gas outlet 4. The gold substrate is placed in a horizontal reactor. In the high-temperature zone of the furnace, gold foil (10 mm × 10 mm × 100 microns, with a purity of 99.99 wt%) is placed in the central area of a horizontal reaction furnace (the diameter of the furnace tube is 25 mm, and the length of the reaction zone is 5 cm); molybdenum trioxide powder (purity 99.999%) 35.6 mg was placed at 3 cm from the front of the gold foil; 150 mg of selenium powder (purity 99.99%) was placed at 350°C in a horizontal reactor, and the reactor was heated to 920°C in an argon atmosphere ( The flow rate of argon gas is 120 ml / min, and the average temp...

Embodiment 3

[0041] 1. Preparation of uniform monolayer molybdenum diselenide single crystal

[0042] Such as figure 1 As shown, a large-size, high-quality, uniform single-layer two-dimensional molybdenum diselenide single crystal is grown in a horizontal reactor. The two ends of the horizontal reactor are respectively provided with a gas inlet 1 and a gas outlet 4. The gold substrate is placed in a horizontal reactor. In the high-temperature zone of the furnace, gold foil (10 mm × 10 mm × 100 microns, with a purity of 99.99 wt%) is placed in the central area of a horizontal reaction furnace (the diameter of the furnace tube is 25 mm, and the length of the reaction zone is 5 cm); molybdenum trioxide powder (purity 99.999%) 13.3 mg was placed at 5 cm from the front of the gold foil; 60 mg of selenium powder (purity 99.99%) was placed at 350°C in a horizontal reactor, and the reactor was heated to 880°C in an argon atmosphere ( The flow rate of argon gas is 100 ml / min, and the average tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com