Transparent and high-water-absorption starch cat litter and preparation process thereof

A high water absorption, starch technology, applied in animal houses, botanical equipment and methods, chemicals for biological control, etc., can solve problems such as easy environmental pollution and poor biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The modified water-absorbing resin is prepared by the following steps:

[0044] Add 3.2g of cornstarch into the flask, add 82mL of deionized water, pregelatinize the starch in an oil bath at 90°C, and stir at 180rpm for 30min, then pass nitrogen into the flask, and lower the temperature to 60°C. Add 4.8g polyglutamic acid, 53mg tert-butyl hydroperoxide, 64mg ethylene glycol glycidyl ether, react for 2 hours, add 96mL of 30% sodium hydroxide solution, react for 1 hour, add glacial acetic acid to adjust the pH To 7, add absolute ethanol to precipitate the precipitate, and dry the precipitate at 80° C. to constant weight to obtain a modified water-absorbent resin.

Embodiment 2

[0046] The modified water-absorbing resin is prepared by the following steps:

[0047] Add 3.6g of tapioca starch into the flask, add 96mL of deionized water, pregelatinize the starch in an oil bath at 92°C, and stir at a speed of 200rpm for 45min, then feed nitrogen into the flask, and lower the temperature to 70°C. Add 5.2g polyglutamic acid, 55mg tert-butyl hydroperoxide, 66mg ethylene glycol glycidyl ether, react for 3 hours, add 104mL sodium hydroxide solution with a mass fraction of 30%, react for 1.5 hours, add glacial acetic acid to adjust When the pH reaches 7.2, absolute ethanol is added to precipitate out the precipitate, and the precipitate is dried at 85° C. to constant weight to obtain a modified water-absorbent resin.

Embodiment 3

[0049] Bacteriostats are made by the following steps:

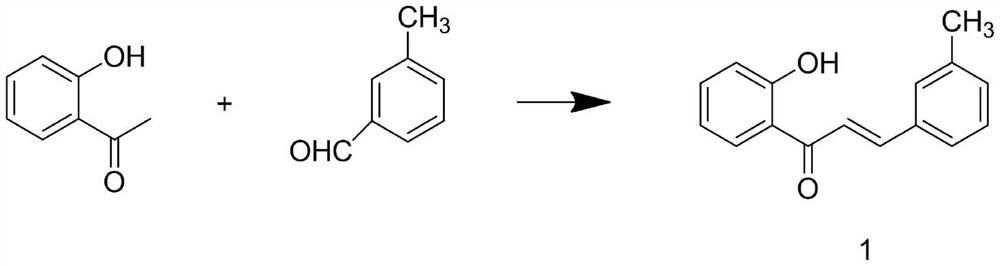

[0050] Step S1, add 1.22mmol o-hydroxyacetophenone, 1.25mmol m-tolualdehyde and 5.3mmol sodium hydroxide into the flask, and add 10mL methanol as a solvent, heat to 100°C and reflux for 2.5h to obtain the intermediate 1;

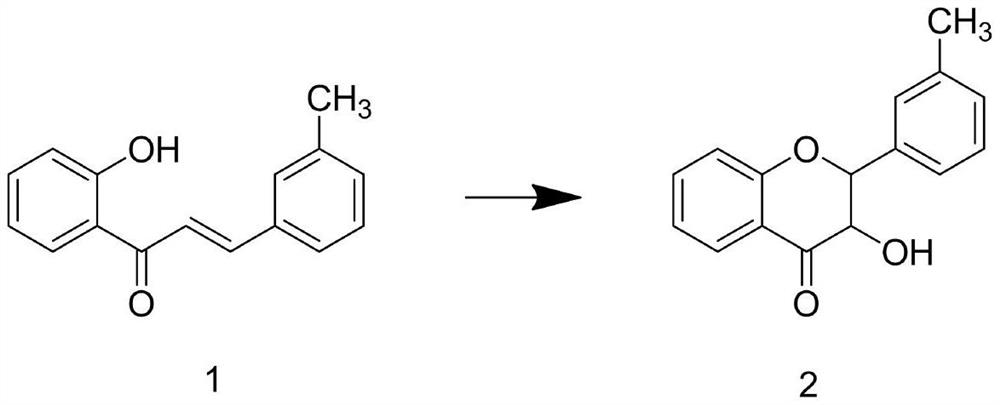

[0051] Step S2, dissolve 1 mmol of intermediate 1 in 40 mL of methanol at 0°C, add 15 mL of 10% sodium hydroxide solution and 10 mL of 30% hydrogen peroxide, stir for 1.5 h, then warm up to room temperature and continue stirring 15h, extracted with ethyl acetate to obtain intermediate 2;

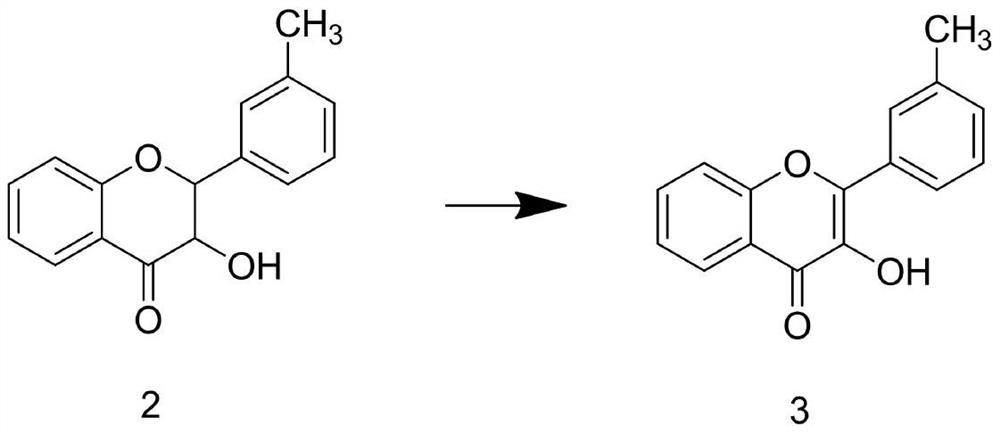

[0052] In step S3, 0.18 mmol of intermediate 2 and 8.45 mmol of anhydrous potassium acetate were dissolved in 7.2 mL of glacial acetic acid at 0° C., 0.36 mmol of iodine was added thereto, and heated to 98° C. for reflux reaction for 4 h. After cooling to room temperature, use Extracted with ethyl acetate to obtain intermediate 3;

[0053] Step S4, add 1 mmol of intermediate 3 and 5 mL of concentrated sulfuric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com