Lithium supplementing current collector and preparation method thereof, lithium supplementing pole piece and lithium battery

A current collector and lithium replenishment technology, which is applied in lithium batteries, secondary batteries, battery electrodes, etc., can solve the problems of poor safety and unstable lithium replenishment technology, and achieves enhanced adhesion, enhanced overall electrochemical performance, and improved Effect of Lithium Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

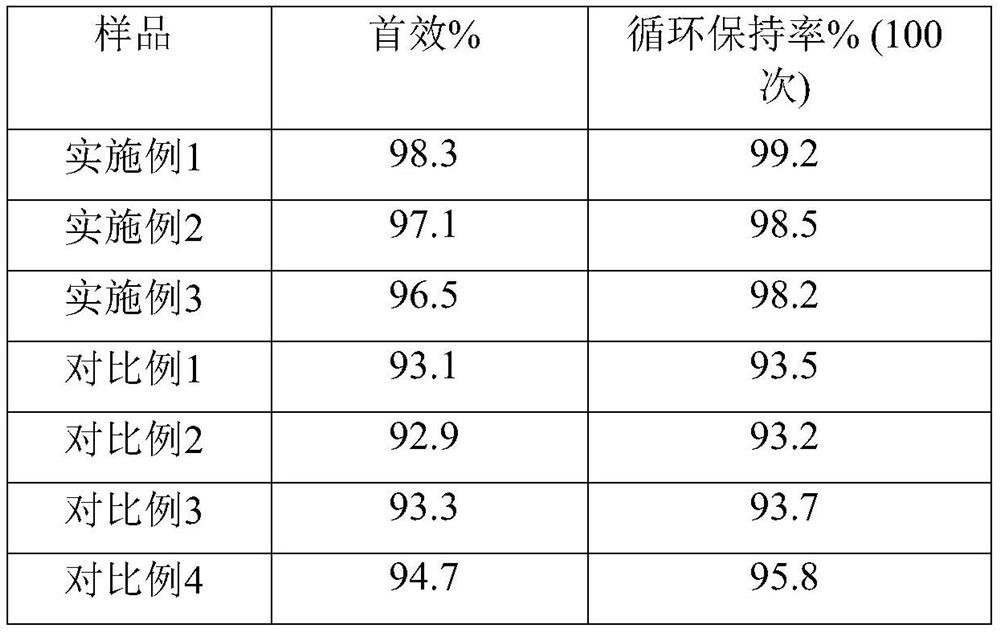

Examples

preparation example Construction

[0037] The embodiment of the present invention also provides a preparation method of the lithium supplement current collector, comprising the following steps:

[0038] placing the lithium-replenishing slurry between preheated rollers of a roller press for rolling to obtain a self-supporting lithium-replenishing coating, and the preheating temperature of the rollers is 50°C to 150°C;

[0039] The self-supporting lithium-supplementing coating is placed on the metal foil 1, and hot-compression lamination is carried out between the preheated rollers.

[0040] In this embodiment, by preheating the rollers of the roller press to an appropriate temperature, adjusting the gap between the two rollers of the roller press, taking an appropriate amount of powder and placing it on the rollers of the roller press, at a certain rolling speed Rolling is carried out to prepare a self-supporting lithium-replenishing coating with a certain thickness. During this process, the first polymer will ...

Embodiment 1

[0062] Use conductive carbon 3 acetylene black (70% by mass) and passivated lithium metal powder (10% by mass) to fully mix the two by ultrasonic dispersion, ultrasonic mixing time 10min, power 20K; then add polyacrylic acid successively (15% by mass) and polytetrafluoroethylene (5% by mass) were sheared and mixed at a speed of 15000rpm with a high-speed ball mill for 20min (pulse-type mixing was used, that is, mixing for 2min, followed by the next 2min after a 1min pause). Mixing), so that different materials are fully dispersed and uniform and produce a certain bonding effect; further transfer the powder to the airflow mill, and perform high-speed airflow shearing to achieve full fibrillation of PTFE and obtain a certain viscosity. Group powder.

[0063] Preheat the rollers of the vertical roller press to 100°C, adjust the gap between the two rollers of the roller press to 4um, take an appropriate amount of powder and place it between the two rollers of the roller press at a...

Embodiment 2

[0068] Conductive carbon 3 Ketjen black (accounting for 80% by mass) and passivated lithium metal powder (accounting for 5% by mass) are fully mixed by mechanical stirring, the stirring rate is 20000rpm, and the stirring time is 10min; Vinylidene fluoride (12% by mass) and polytetrafluoroethylene (3% by mass) were sheared and mixed at a speed of 12000 rpm for 15 minutes in a high-speed ball mill (pulse mixing was used, that is, mixing for 2 minutes, and then proceeded to the next step after 1 minute of rest. One 2min mixing), so that the different materials are fully dispersed and uniform and produce a certain bonding effect; further transfer the powder to the airflow mill, and perform high-speed airflow shearing to achieve full fibrillation of PTFE and obtain a certain viscous agglomerated powder;

[0069] Preheat the rollers of the vertical roller press to 115°C, adjust the gap between the two rollers of the roller press to 3um, take an appropriate amount of powder and place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com