Preparation method of ternary oxide ozone catalyst for advanced treatment of wastewater

A ternary oxide, advanced treatment technology, applied in the field of environmental catalysis and water treatment, can solve the problems of low utilization rate of substrate pores and easy agglomeration of active components, so as to improve the utilization rate of ozone, increase the depth of immersion, and reduce deactivation. effect of phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method for a ternary oxide ozone catalyst for advanced treatment of wastewater, the steps of which are as follows:

[0030] Gamma-Al with a particle size of 2-5mm and a weight of 100g 2 o 3 The carrier is soaked with 10% dilute nitric acid solution by weight to ensure that the liquid fully infiltrates the carrier. The soaking time is 12 hours. After soaking, it is cleaned with deionized water until the pH is basically unchanged, then transferred to the oven for drying, and set aside;

[0031]Use ethylenediaminetetraacetic acid as a metal ion accelerator, add it to a certain volume of deionized water, and after it is fully dissolved, add ferric nitrate, copper nitrate and lanthanum nitrate to the above solution in sequence, and then prepare the impregnation reserve liquid. Wherein, the weight of each component of the impregnation stock solution: ethylenediaminetetraacetic acid, iron nitrate, manganese nitrate and deionized water are respectively 5g, 15g, ...

Embodiment 2

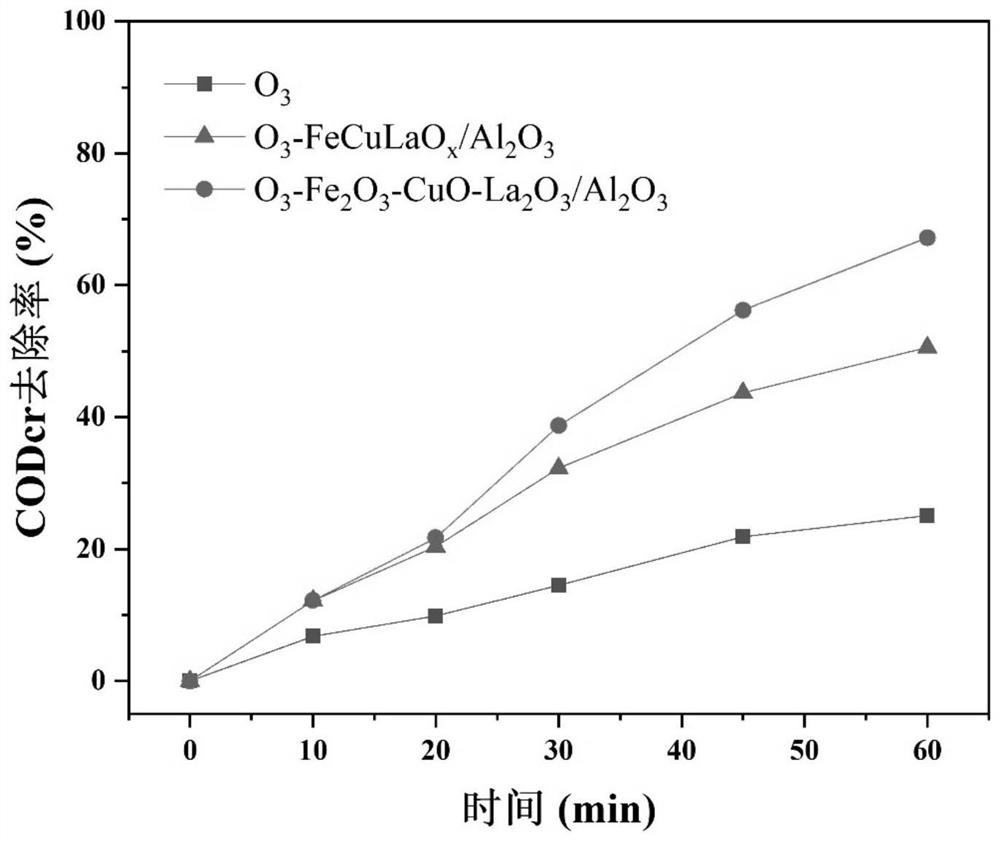

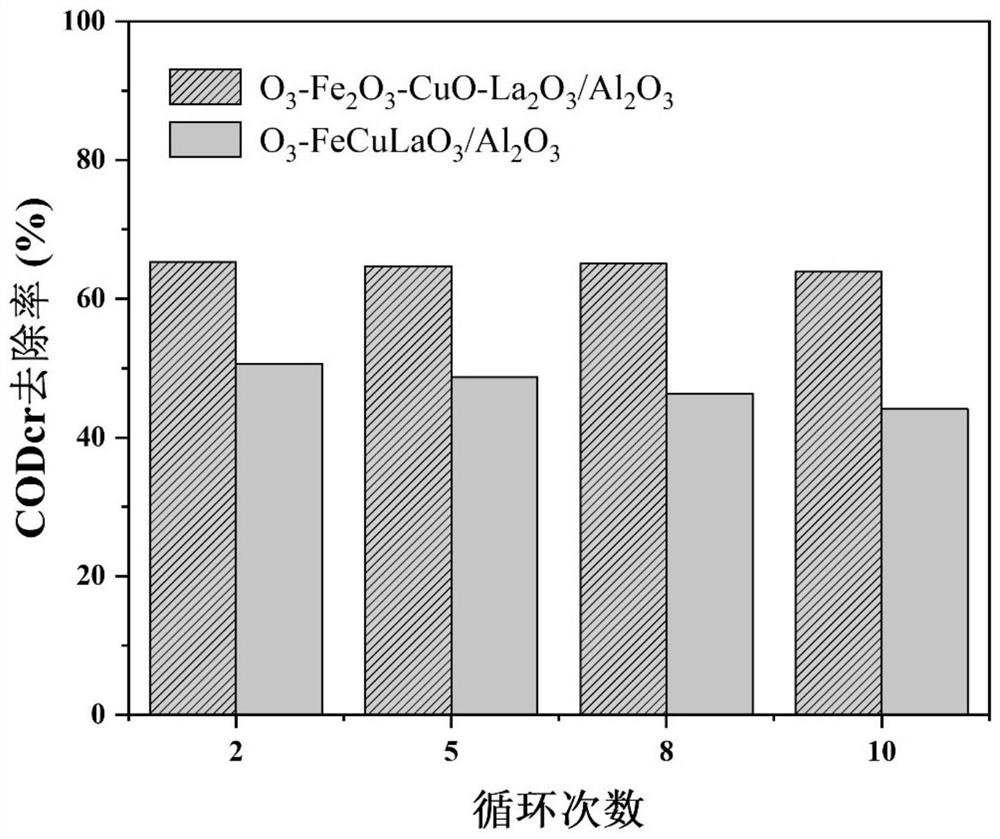

[0043] The ozone catalyst used for water treatment in Example 1 and Comparative Example 1 was collected, washed, dried and transferred to a muffle furnace at 300 ° C for 2 hours and calcined, then cooled and taken out and used for the treatment of simulated dye wastewater, and the degradation test was maintained. The conditions are the same as in Example 1. The above two catalysts were subjected to 10 repeated degradation tests, and the test results were as follows Figure 4 The results show that compared with the traditional impregnation process, which easily leads to the agglomeration of catalytic species on the surface of the carrier, the introduction of metal ion promoters in the catalyst preparation process helps to improve the uniform dispersion of active species, increase the number of catalytic ozone active sites, and accelerate ozone. Catalytic oxidation efficiency, even after 10 repeated tests, the ozone catalyst prepared by the invention still has the performance of...

Embodiment 3

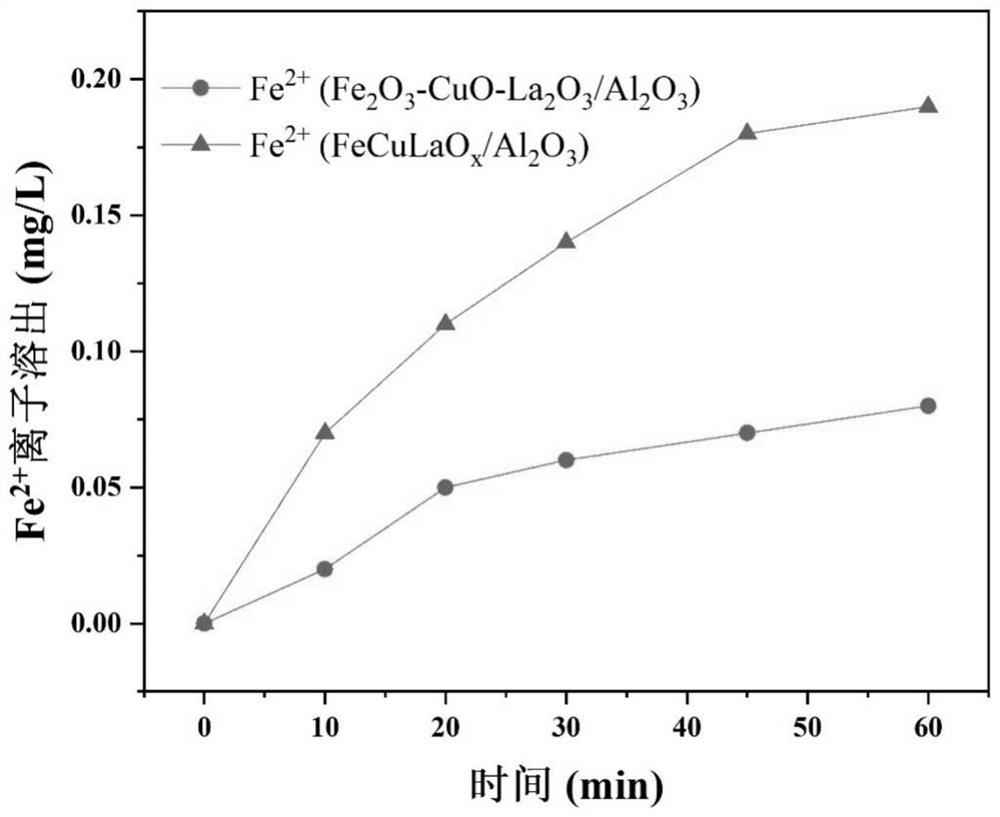

[0045] Based on the cyclic test carried out in Example 2, the third cyclic degradation experiment was selected, after taking out 5 mL of the reaction solution at different time periods, respectively, transferred to a 10 mL colorimetric tube, and successively added 1 mL of hydroxylamine hydrochloride with a concentration of 1 g / L, 2 mL of acetic acid with a concentration of 1 mol / L and 2 mL of a solution of o-phenanthroline with a concentration of 1 g / L were allowed to stand for 15 min, and the total iron content dissolved in the reaction solution was measured by spectrophotometry at a wavelength of 510 nm. The experimental results are as image 3 As shown, after 60 min of degradation experiment, FeCuLaOx / Al 2 O 3 The total dissolved iron ion in the catalytic system reaches 0.19mg / L, which is much higher than Fe 2 O 3 -CuO-La 2 O 3 / Al 2 O 3 0.08mg / L in the catalytic system. FeCuLaOx / Al 2 O 3 The loss of excess active components in the catalytic system confirms a redu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com