3D printing method for preparing metal artificial bone on basis of slurry direct writing

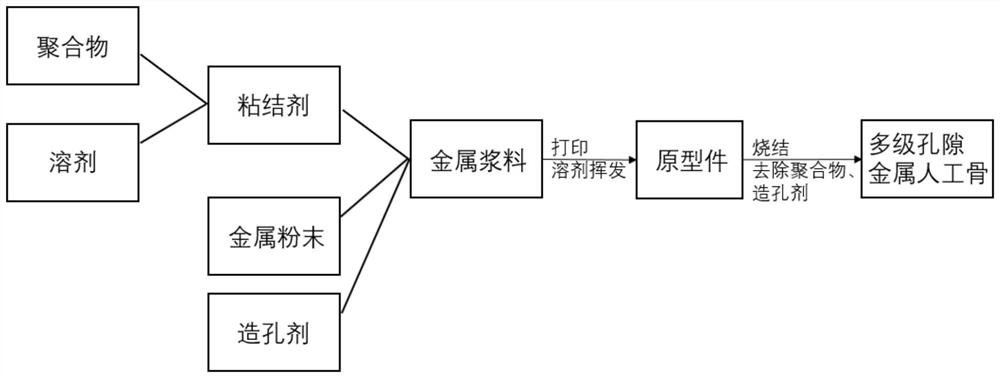

A 3D printing and artificial bone technology, which is applied in metal processing equipment, additive manufacturing, additive processing, etc., can solve the problems of matching and the inability of the metal artificial bone bracket to adjust the structural porosity and mechanical properties at the same time, so as to promote the elastic modulus Reduce and improve the effect of stress shielding and avoid melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

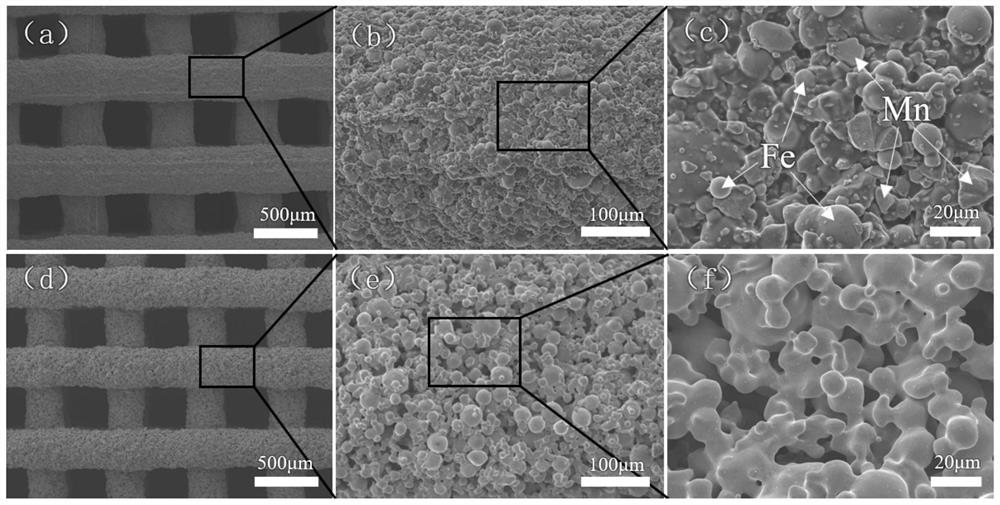

[0030] Example 1 The metal powder for printing is iron powder, the binder solvent is dichloromethane DCM, and the polymer is polylactic acid PLA;

[0031] Include the following steps:

[0032] (1) Before mixing the metal slurry, weigh the mass ratio of the polymer to the solvent to be 1:4, dissolve the polymer and the solvent in a sealed container for 6 hours, and prepare a uniform, flowable, and certain viscosity slurry binder;

[0033] (2) Weigh the printing metal powder with a diameter of 5-45 microns and the manganese powder with an irregular particle size of about 5-8 microns as a pore-forming agent according to the volume ratio of 1:0.1, and according to the viscosity of the slurry The mass ratio of the binder to the total metal powder is 1:5, put it into a ball mill and mix it for 30 minutes at a speed of 500r / min to obtain a uniformly mixed metal slurry;

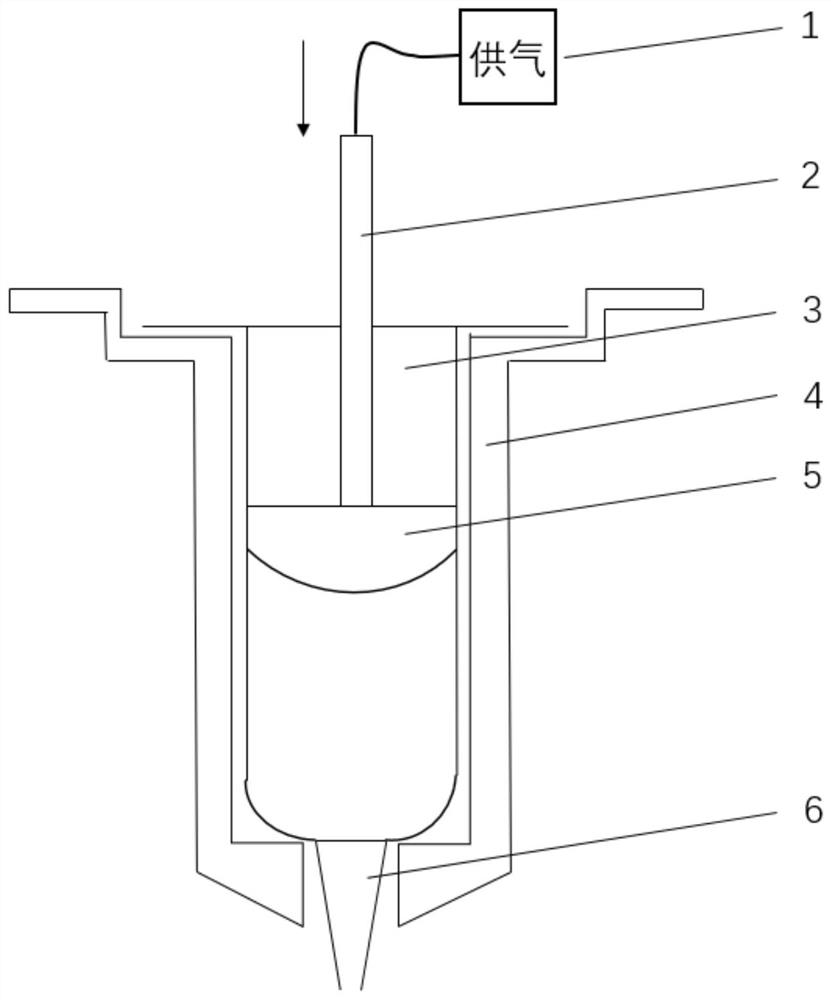

[0034] (3) Put the metal slurry into the barrel 3, and after being clamped by the clamp 4, a stable air pressure...

Embodiment 2

[0042] Example 2 The metal powder for printing is titanium alloy powder, the binder solvent is dichloromethane DCM, and the polymer is polystyrene PS;

[0043] Include the following steps:

[0044] (1) Before mixing the metal slurry, weigh the mass ratio of the polymer to the solvent to be 1:3, dissolve the polymer and the solvent in a sealed container for 12 hours, and prepare a uniform, flowable, and certain viscosity slurry binder;

[0045] (2) Weigh the printing metal powder with a diameter of 30-70 microns and the irregular manganese powder with a particle size of 9-12 microns as a pore-forming agent according to the volume ratio of 1:1, and bond them according to the slurry The mass ratio of agent to total metal powder is 1:4, put it into a ball mill and mix it for 45 minutes at a speed of 800r / min to obtain a uniformly mixed metal slurry;

[0046] (3) Put the metal slurry into the barrel 3, and after being clamped by the clamp 4, a stable air pressure is introduced, a...

Embodiment 3

[0054] Embodiment 3 The printing metal powder is made of stainless steel, the binder solvent is made of water, and the polymer is made of polyvinyl alcohol PVA and polyethylene glycol PEG.

[0055] Include the following steps:

[0056] (1) Before mixing the metal slurry, weigh the mass ratio of the polymer PVA to PEG to be 2:1, and the mass ratio of the polymer to the solvent to be 1:5, and dissolve the polymer and the solvent in a sealed container for 9 hours to prepare Uniform, flowable, and viscous slurry binder;

[0057] (2) Weigh the printing metal powder with a diameter of 70-100 microns and the manganese powder with an irregular particle size of about 12-15 microns as a pore-forming agent according to the volume ratio of 1:2.4, and weigh them according to the slurry The mass ratio of the binder to the total metal powder is 1:3, put it into a ball mill and mix it for 60 minutes at a speed of 200r / min to obtain a uniformly mixed metal slurry;

[0058] (3) Put the metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com