Preparation method of fumaric acid pour point depressant for crude oil

A pour point depressant, the technology of Fuma, which is used in mechanical equipment, processing of hydrocarbon oil, petroleum industry, etc., can solve problems such as poor salt resistance, and achieve the effect of easy storage, good pour point and viscosity reduction effect, and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

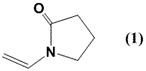

[0058] (1) Dissolve 400.0g of vinyl acetate, 75.0g of N-vinylpyrrolidone and 25.0g of 2-(N-acryloyloxy)ethylpyrrolidone into 495.0g of ethanol respectively, blow in nitrogen, and then heat up to 65°C. Add 5.0 g of azobisisobutyronitrile, stir evenly and react for 3 hours to obtain the first prepolymer;

[0059] (2) Weigh 480.0g of fumaric acid, 0.9g of allyl polyoxyethylene acetate and 19.1g of allyl alcohol polyoxyethylene ether into 100.0g of dimethyl sulfoxide and 395.0g of deionized water, and pass through Nitrogen, then warm up to 55°C, add 5.0g of potassium persulfate, stir evenly and react for 4h to obtain the second prepolymer;

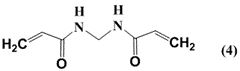

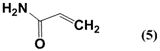

[0060] (3) Weigh 500.0g of the second prepolymer, heat up to 85°C, add 62.5g of tetradecyl alcohol, 12.5g of cetyl alcohol, 37.5g of stearyl alcohol, 37.5g of eicosanol and 2.5g of phosphoric acid, and stir for 1 hour. ; Then add 100.0g of the first prepolymer, 90.0g of acrylamide, 10.0g of N-(hydroxymethyl)acrylamide and 0.3 g of sodium meth...

Embodiment 2

[0062] (1) Dissolve 300.0g of vinyl acetate, 15.0g of N-vinylpyrrolidone and 15.0g of 2-(N-acryloyloxy)ethylpyrrolidone into 668.0g of ethanol respectively, blow in nitrogen, and then heat up to 60°C. Add 2.0 g of azobisisobutyronitrile, stir evenly and react for 5 hours to obtain the first prepolymer;

[0063] Steps (2) (3) are the same as in Example 1 to prepare pour point depressant 2#.

Embodiment 3

[0065] (1) Weigh 350.0g of vinyl acetate, 300.0g of N-vinylpyrrolidone, and 50.0g of 2-(N-acryloyloxy)ethylpyrrolidone and dissolve them in 290.0g of ethanol, blow in nitrogen, and then heat up to 75°C. Add 10.0 g of azobisisobutyronitrile, stir evenly and react for 1 hour to obtain the first prepolymer;

[0066] Steps (2) and (3) are the same as in Example 1 to prepare pour point depressant 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com