Method for preparing MOF/carbon composite material under assistance of atomic layer deposition, obtained product and application

A technology of carbon composite materials and atomic layer deposition, applied in the direction of heat exchange materials, chemical instruments and methods, metal material coating technology, etc., can solve the problems of MOF particle agglomeration, keep the structure unchanged, and the preparation process is simple and easy The effect of improving the electromagnetic wave absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

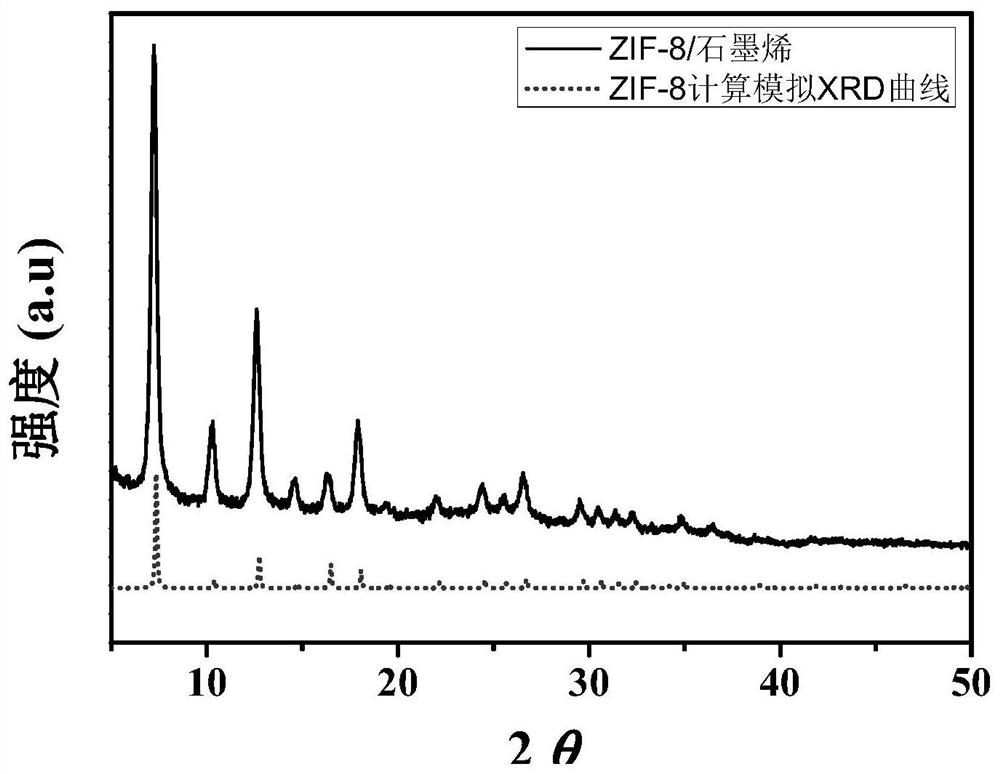

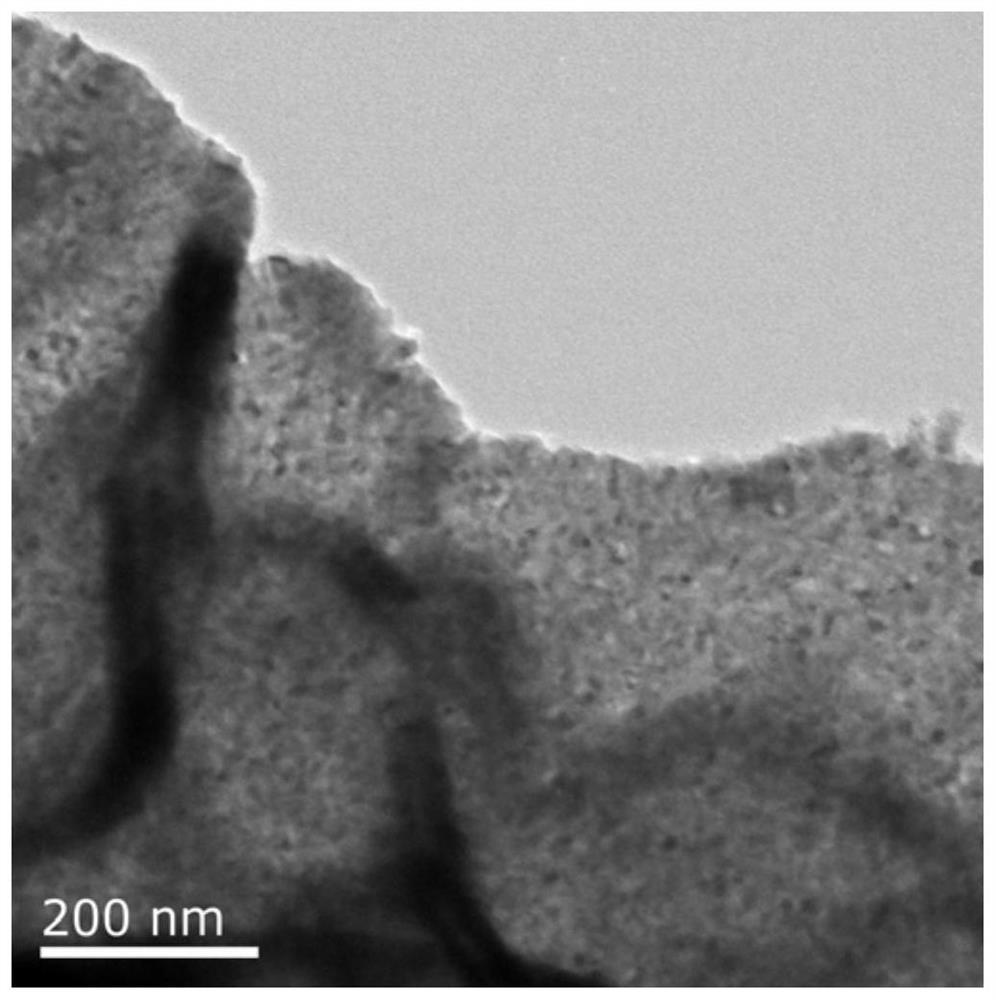

[0038] The preparation of different thickness ZIF-8 / graphene nanocomposites, the method is as follows:

[0039] 1. Graphene pretreatment

[0040]Take 20 mg of graphene with a sheet diameter of about 2 microns and a thickness of about 2 nanometers, dissolve it in a transparent vial of 15 ml of absolute ethanol, and ultrasonicate it for 15 minutes until there is no agglomeration, and use a rubber dropper to judge whether it is dispersed Evenly, a graphene dispersion is obtained.

[0041] 2. Preparation of ZnO / graphene composites with different thicknesses

[0042] Use a rubber dropper to evenly drop the graphene dispersion on the glass sheet. The thickness of the dispersion is about 2 mm. After natural drying, start the closed hot-wall reactor to deposit zinc oxide. Set the reaction temperature to 120 °C , turn on the water source, ozone, diethyl zinc source and inert gas pipeline, after setting the number of pulse cycles, run the program to deposit zinc oxide, after the growt...

Embodiment 2

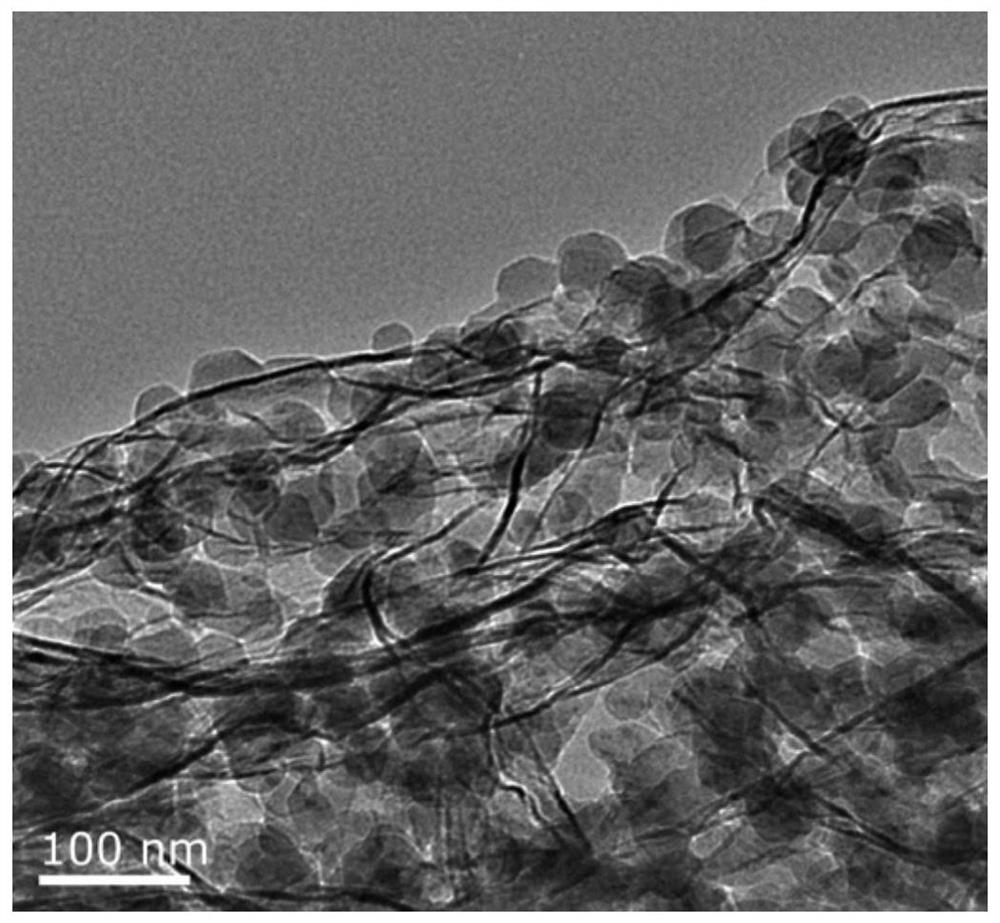

[0056] 1. Carbon nanotube pretreatment

[0057] Take 20 mg of carbon nanotubes with a diameter of 3-15 and a nanotube length of 15-30 microns, and dissolve them in a transparent vial of 15 ml of absolute ethanol. The tubes are judged to be uniformly dispersed to obtain a carbon nanotube dispersion.

[0058] 2. Preparation of zinc oxide / carbon nanotube composites

[0059] Zinc oxide was deposited on the surface of carbon nanotubes according to the method in Example 1, and the deposition cycle was 50 cycles.

[0060] 3. Preparation of particle size ZIF-8 / carbon nanotube composites

[0061] Take 100 mg of ZnO / carbon nanotube composite material, disperse it in 15 mL of methanol, then drop the resulting dispersion into 15 mL of 8mol / L dimethylimidazole solution (methanol is the solvent), stir at room temperature for 2 h, and then centrifuge to obtain The product was washed 3 times with methanol, and then placed in a vacuum oven at 60 °C for 10 h to obtain a ZIF-8 / carbon nanotube...

Embodiment 3

[0063] The carbon nanotubes in Example 2 were replaced with carbon fibers to prepare a ZIF-8 / carbon fiber composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com