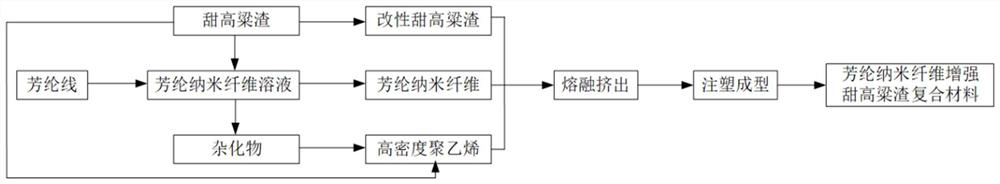

Preparation method of aramid nanofiber reinforced sweet sorghum residue composite material

A technology of nanofibers and composite materials, applied in the field of new composite materials, can solve the problems of low mechanical strength, improve mechanical properties, realize high-value utilization, and increase the use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Crush the sweet sorghum slag to 140 mesh, put it in a 60°C oven and dry it for 24 hours to reduce the moisture content to 2%;

[0043] 2) Treat sweet sorghum slag with dimethyl sulfoxide / potassium hydroxide system, the mass volume ratio of fiber and solution is 1:10, stir at room temperature for 24 hours, wash the mixture until neutral, and obtain modified sweet sorghum slag after drying .

[0044] 3) Weighing raw materials according to parts by weight: 40 parts of modified sweet sorghum slag, 60 parts of high-density polyethylene, and 5 parts of polyethylene wax, and fully mixed to obtain a uniform mixture.

[0045] 4) Put the well-mixed materials into a conical twin-screw extruder for melt blending, and extrude them into a barrel. The extruder speed is 60r / min, and the extrusion temperature and barrel temperature are both 175°C.

[0046] 5) The mixture is put into a micro-injection molding machine through a barrel for injection molding to obtain the required mater...

Embodiment 2

[0048] 1) Crush the sweet sorghum slag to 140 mesh, put it in a 60°C oven and dry it for 24 hours to reduce the moisture content to 2%;

[0049] 2) Wash the aramid thread three times with ethanol to remove surface impurities, and dry it in a 60°C oven for 24 hours;

[0050] 3) Prepare a 2 mg / ml aramid nanofiber solution using dimethyl sulfoxide / potassium hydroxide system, stir at room temperature for 24 hours, and then freeze-dry the obtained homogeneous mixture at -80°C for a freezing time of 24h, obtain freeze-dried aramid fiber nanofiber;

[0051]4) Weigh raw materials by weight: 40 parts of unmodified sweet sorghum slag, 50 parts of high-density polyethylene, 10 parts of freeze-dried aramid nanofibers, and 5 parts of polyethylene wax, and fully mix to obtain a uniform mixture.

[0052] 5) Put the well-mixed materials into a conical twin-screw extruder for melt blending, and extrude into the barrel, the speed of the extruder is 60r / min, and the extrusion temperature and ba...

Embodiment 3

[0055] 1) Screen 140-mesh sweet sorghum slag and put it in a 60°C oven to dry for 24 hours to reduce the moisture content to 2%;

[0056] 2) Wash the aramid thread three times with ethanol to remove surface impurities, and dry it in a 60°C oven;

[0057] 3) A 2 mg / ml aramid nanofiber solution was prepared using a dimethyl sulfoxide / potassium hydroxide system, and stirred at room temperature for 24 hours.

[0058] 4) Put 7 g of sweet sorghum slag in 500 ml of aramid nanofiber solution, stir at room temperature for 72 hours, so that sweet sorghum slag is evenly dispersed in the aramid nanofiber solution, the mixture is washed with water until neutral, and dried in an oven at 60°C. The sweet sorghum slag aramid fiber nanofiber hybrid is obtained.

[0059] 5) Weigh raw materials by weight: 50 parts of sweet sorghum slag and nanofiber hybrid; 50 parts of high-density polyethylene; 5 parts of polyethylene wax, fully mixed at room temperature to obtain a uniform mixture.

[0060] 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com