Foamed nickel-based erbium-doped nickel-cobalt bimetallic phosphide nano array as well as preparation method and application thereof

A nano-array, nickel foam technology, applied in electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of low catalytic activity, long-term corrosion resistance, unsatisfactory electrocatalytic performance and practical industrial application, etc., and achieve catalytic activity. High, improve the intrinsic catalytic activity, optimize the effect of Gibbs free energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

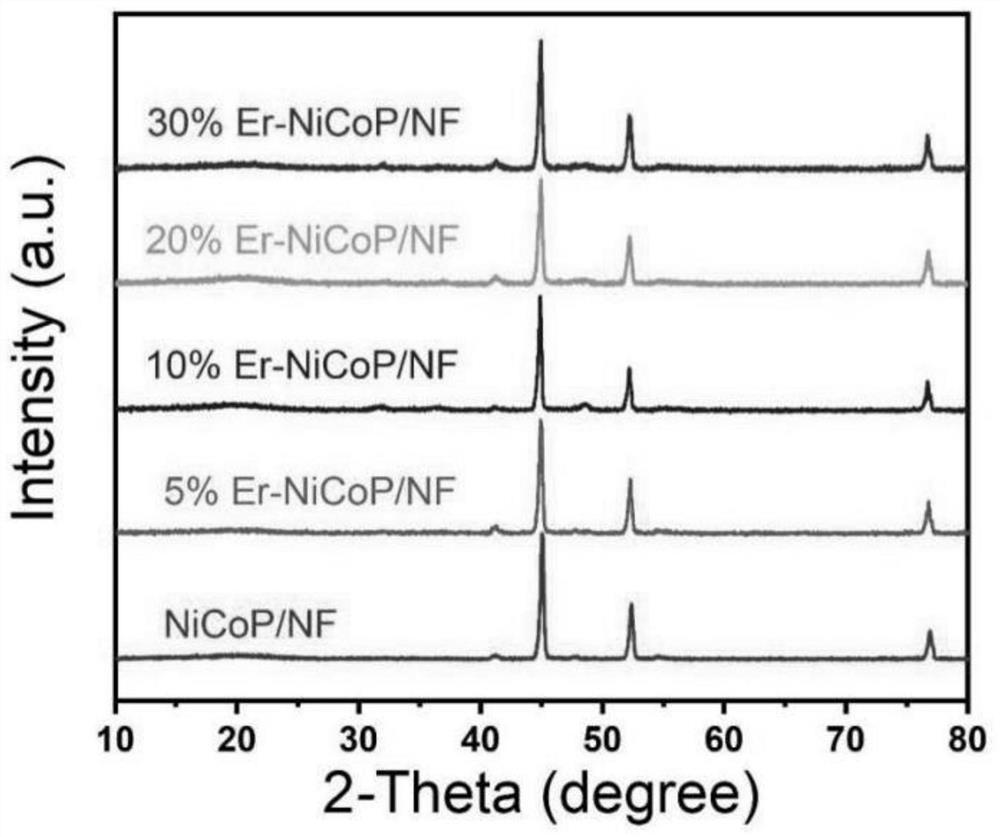

[0031] The present invention provides a kind of preparation method of nickel-cobalt bimetallic phosphide nano-array (Er-NiCoP / NF) doped with foam nickel-based erbium, comprising the following steps:

[0032] Mixing soluble trivalent erbium salt, soluble divalent nickel salt, soluble divalent cobalt salt, urea, ammonium fluoride and water to obtain a mixed solution;

[0033] Soaking the nickel foam with the mixed solution and then performing a hydrothermal reaction to obtain a hydrothermal product;

[0034] The phosphorus source and the hydrothermal product are calcined in a protective atmosphere to obtain the nickel-cobalt double-metal phosphide nano-array doped with nickel-based erbium foam.

[0035] In the present invention, the source of each raw material is not particularly limited, and commercially available products well known to those skilled in the art can be used.

[0036] The invention mixes soluble trivalent erbium salt, soluble divalent nickel salt, soluble divale...

Embodiment 1

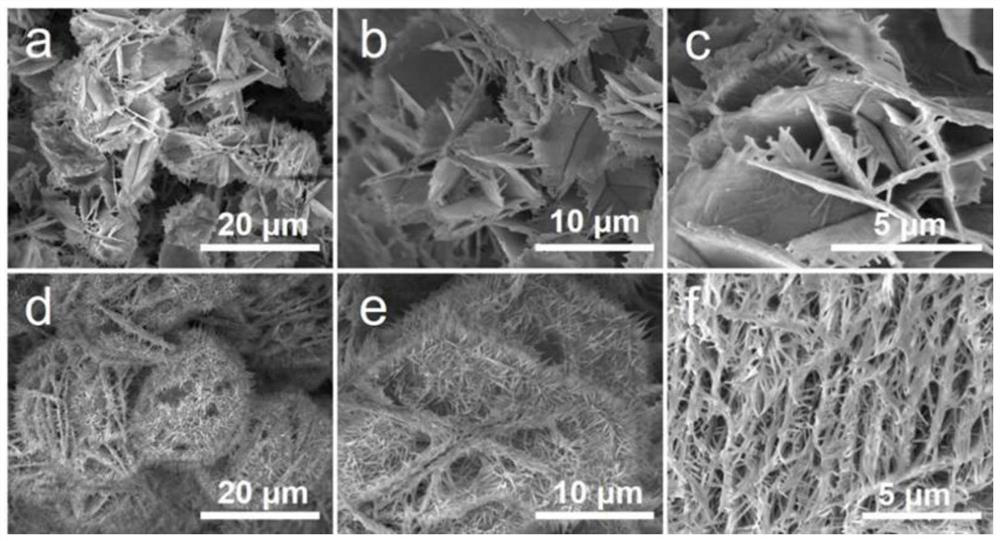

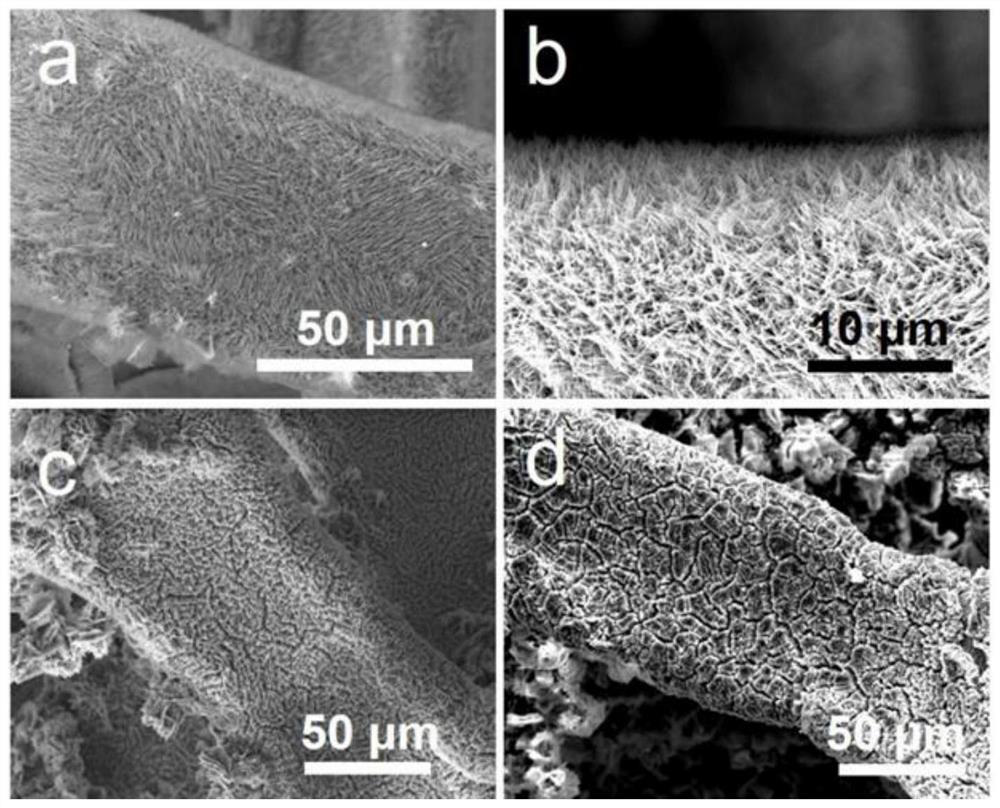

[0062] 1mmol Ni(NO 3 ) 2 ·6H 2 O, 1mmol Co(NO 3 ) 2 ·6H 2 O, urea (6mmol) and NH 4 F (2.5 mmol) was dissolved in 30 mL of water, and after stirring for 30 minutes, it was aged at room temperature for 1 hour. The solution was then transferred to a 50 mL stainless steel autoclave lined with Teflon, and a piece of nickel foam (area 6 cm 2 , with a thickness of 1.5mm and a surface density of 350g·cm -2 ) was immersed in the reaction solution and kept at 120° C. for 6 hours. When the temperature was cooled to room temperature, the obtained NiCo nanowire array precursor (NiCo NWAs precursor / NF) was washed once with water and ethanol, and dried overnight at 60 °C in a vacuum drying oven.

[0063] NaH 2 PO 2 ·H 2 O (500 mg) and pre-prepared NiCo NWAs precursor / NF were placed on the upstream side and center of the tube furnace, respectively. The sample was then calcined at 350 °C for 2 h in an Ar atmosphere with a heating rate of 2 °C min -1 . Finally, NiCoP / NF was obtain...

Embodiment 2

[0065] 1mmol Ni(NO 3 ) 2 ·6H 2 O, 1mmol Co(NO 3 ) 2 ·6H 2 O, 0.05mmol Er(NO 3 ) 3 ·6H 2 O (molar ratio Er:Ni=5%), urea (6mmol) and NH 4 F (2.5 mmol) was dissolved in 30 mL of water, and after stirring for 30 minutes, it was aged at room temperature for 1 hour. The solution was then transferred to a 50 mL stainless steel autoclave lined with Teflon, and a piece of nickel foam (area 6 cm 2 , with a thickness of 1.5mm and a surface density of 350g·cm -2 ) into the reaction solution and kept at 100°C for 10 hours. When the temperature was cooled to room temperature, the obtained Er-doped NiCo nanowire array precursor (Er-NiCo NWAs precursor / NF) was washed several times with water and ethanol, and dried overnight at 60 °C in a vacuum oven.

[0066] NaH 2 PO 2 ·H 2 O (500 mg) and pre-prepared Er-NiCo NWAs precursor / NF were placed on the upstream side and center of the tube furnace, respectively. The sample was then calcined at 300 °C for 3 h in an Ar atmosphere with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com