Microwave absorbent based on synergistic coupling protection and preparation method thereof

A microwave absorbent and solvent technology, which is used in textiles and papermaking, fiber processing, fiber chemical characteristics, etc., can solve problems such as large specific gravity, and achieve the effects of low cost, improved load uniformity, and a wide range of sources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A microwave absorber based on cooperative coupling protection, the microwave absorber uses ferrite fiber as a carrier and supports ferrite and barium titanate composite fibers made of barium titanate nanoparticles.

[0026] A method for preparing a microwave absorber based on cooperative coupling protection, comprising the steps of:

[0027] S1 Prepare the spinning solution, add 2.91g of cobalt nitrate and 8.08g of iron nitrate into 50mL deionized water, stir for 30 minutes to obtain solution A; weigh 1g of polyvinylpyrrolidone and add it to 9ml of ethanol, stir for 3 hours to obtain Solution B; adding solution B to solution A and stirring for 5 hours to obtain a spinning solution;

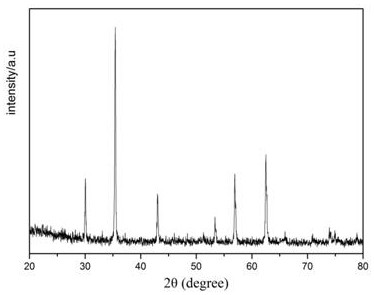

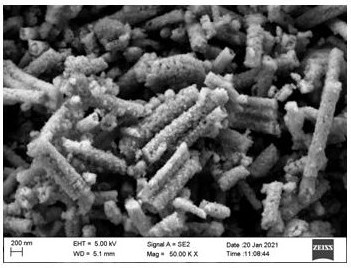

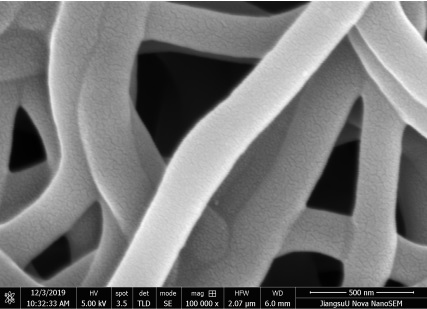

[0028] S2 Preparation of ferrite fibers, using sol electrospinning process, under the conditions of 15kV voltage, receiving distance 15cm, needle diameter 0.9mm, liquid output rate 1mL / h to prepare precursor fibers, calcined at 550°C for 2h to obtain ferrite fiber, its XRD and SEM images a...

Embodiment 2

[0032] A microwave absorber based on cooperative coupling protection, the microwave absorber uses ferrite fiber as a carrier and supports ferrite and barium titanate composite fibers made of barium titanate nanoparticles.

[0033] A method for preparing a microwave absorber based on cooperative coupling protection, comprising the steps of:

[0034] S1 Prepare the spinning solution, add 2.91g of cobalt nitrate and 8.08g of iron nitrate into 50mL deionized water, stir for 30 minutes to obtain solution A; weigh 1g of polyvinylpyrrolidone and add it to 9ml of ethanol, stir for 3 hours to obtain Solution B; adding solution B to solution A and stirring for 3 hours to obtain a spinning solution;

[0035] S2 Preparation of ferrite fibers, using sol electrospinning process, under the conditions of 15kV voltage, receiving distance 15cm, needle diameter 0.9mm, liquid output rate 1mL / h to prepare precursor fibers, calcined at 550°C for 2h to obtain ferrite fiber;

[0036] S3 Prepare abs...

Embodiment 3

[0039] A microwave absorber based on cooperative coupling protection, the microwave absorber uses ferrite fiber as a carrier and supports ferrite and barium titanate composite fibers made of barium titanate nanoparticles.

[0040] A method for preparing a microwave absorber based on cooperative coupling protection, comprising the steps of:

[0041] S1 prepares spinning solution, gets the nickel nitrate of 2.91g and the ferric nitrate of 8.08g and joins in 50mL deionized water, stirs for 30 minutes to obtain solution A; Takes the polyvinylpyrrolidone of 1.25g and joins in the ethanol of 10.2ml, stirs for 3 Obtain solution B in 1 hour; Add B solution in A solution, stir for 5 hours, obtain spinning solution;

[0042] S2 prepares ferrite fiber, adopts sol electrospinning process, prepares precursor fiber under the conditions of 20kV voltage, receiving distance 15cm, needle diameter 0.4mm, liquid output rate 1mL / h, and calcines at 650°C for 5h to obtain ferrite fiber;

[0043] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| absorption bandwidth | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com