Ultrathin polyimide film and preparation method thereof

A technology of polyimide film and polyamic acid, which is applied in the field of biomedical sensors, can solve problems such as low bending stiffness, high temperature resistance of the film, and biological rejection, and achieve low bending stiffness, easy to fit curved surfaces, and manufacture The method is simple and stable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment provides a kind of preparation method of ultra-thin polyimide film, comprising:

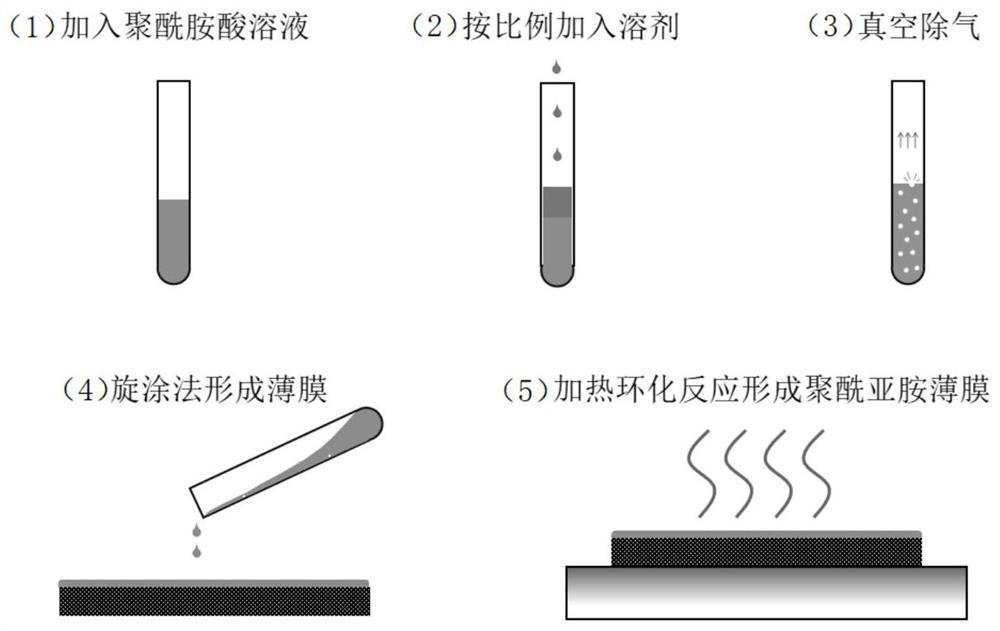

[0030] refer to figure 2 As shown in (1), take 5ml of Fuji Durimide7505 type solution and pour it into a graduated cylinder.

[0031] refer to figure 2 As shown in (2), take 5ml of N-methyrrolidone (NMP) (N-methylpyrrolidone) and pour it into the previous measuring cylinder, then put it into a vortex mixer and mix it for 2 minutes, then put the mixed solution into The roller mixer was mixed for 5 minutes to fully mix the added NMP solvent and Durimide7505 solution.

[0032] refer to figure 2 As shown in (3), put the measuring cylinder into the vacuum dish and degas it with a vacuum pump. The vacuum degree should be lower than 10 3 Pa, the holding time is not less than 3 minutes.

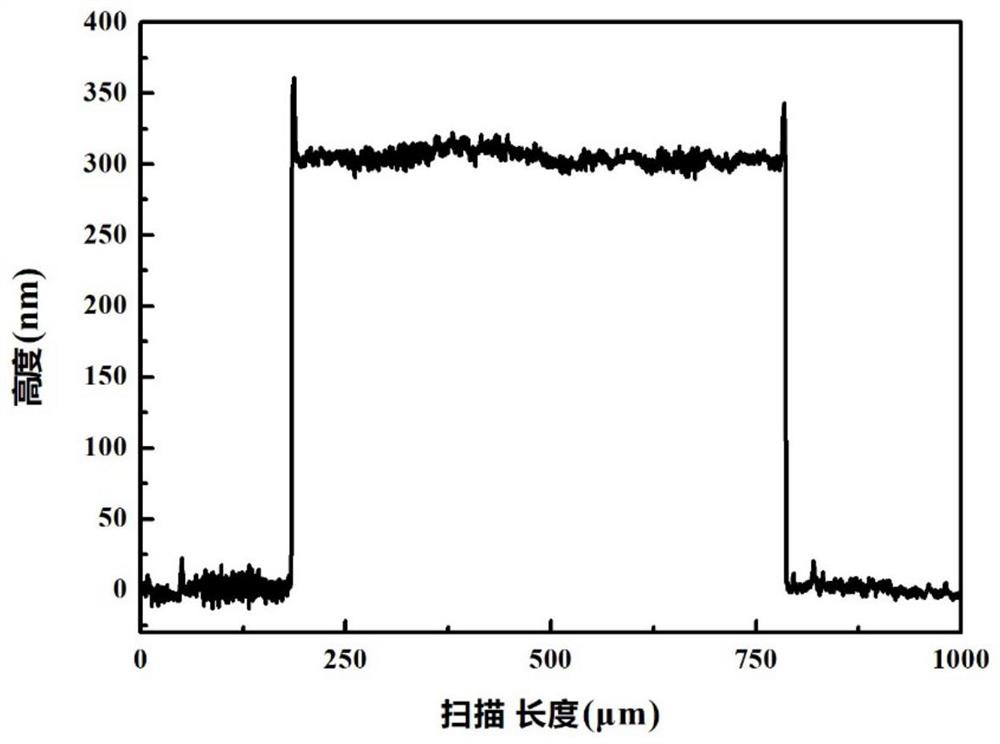

[0033] refer to figure 2 As shown in (4), spin-coat the degassed mixed solution onto the surface of a clean and polished silicon wafer with a homogenizer at a speed of 3000 rpm fo...

Embodiment 2

[0037] The present embodiment provides a kind of preparation method of ultra-thin polyimide film, comprising:

[0038] refer to figure 2 As shown in (1), take 6ml of Fuji Durimide7505 type solution and pour it into the graduated cylinder.

[0039] refer to figure 2As shown in (2), take 4ml of N-methyrrolidone (NMP) (N-methylpyrrolidone) and pour it into the previous measuring cylinder, then put it into a vortex mixer and mix it for 2 minutes, then put the mixed solution into The roller mixer was mixed for 5 minutes to fully mix the N-methylpyrrolidone solvent and the Fuji Durimide 7505 solution.

[0040] refer to figure 2 As shown in (3), put the measuring cylinder into the vacuum dish and degas it with a vacuum pump. The vacuum degree should be lower than 10 3 Pa, the holding time is not less than 3 minutes.

[0041] refer to figure 2 As shown in (4), the degassed solution is spin-coated on the surface of a clean and polished silicon wafer with a glue equalizer, and...

Embodiment 3

[0045] The present embodiment provides a kind of preparation method of ultra-thin polyimide film, comprising:

[0046] refer to figure 2 As shown in (1), take 8ml of Fuji Durimide7505 type solution and pour it into the graduated cylinder.

[0047] refer to figure 2 As shown in (2), take 2ml of N-methyrrolidone (NMP) (N-methylpyrrolidone) and pour it into the previous measuring cylinder, then put it into a vortex mixer and mix it for 2 minutes, then put the mixed solution into The roller mixer was mixed for 5 minutes to fully mix the N-methylpyrrolidone solvent and the Fuji Durimide 7505 solution.

[0048] refer to figure 2 As shown in (3), put the measuring cylinder into the vacuum dish and degas it with a vacuum pump. The vacuum degree should be lower than 10 3 Pa, the holding time is not less than 3 minutes.

[0049] refer to figure 2 As shown in (4), the degassed solution is spin-coated on the surface of a clean and polished silicon wafer with a glue equalizer, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com