Low-surface-energy hydrophobic dental resin and preparation method thereof

A resin, low viscosity technology, used in dental preparations, dentistry, dental prostheses, etc., can solve the problem of high morbidity, and achieve the effects of large hydrophobicity, small volume shrinkage, and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

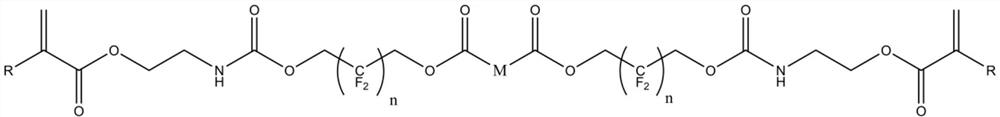

[0051] AF 4 CH 3 Synthesis

[0052] Add 5.24g of octafluoro-1,6-hexanediol, 50mL of tetrahydrofuran and 0.01g of dibutyltin dilaurate into a round-bottomed flask equipped with a magnet, mix well and raise the temperature to 60°C. Dissolve 2.22 g of isophorone diisocyanate in 50 mL of tetrahydrofuran, drop it into a round bottom flask through a constant pressure dropping funnel over 2 hours, and react at 60°C for 10 hours after the addition is complete until the isocyanate groups in the system are completely reacted. Weigh 3.10g of isocyanatoethyl methacrylate and 0.01g of p-hydroxyanisole into the reaction system, continue the reaction at 60°C for 16 hours until the isocyanate group in the system is completely reacted, and after cooling to room temperature, the reaction The product was purified to obtain AF 4 CH 3 .

Embodiment 2

[0054] AF 8 CH 3 Synthesis

[0055] Add 9.24g of 1H,1H,10H,10H-perfluoro-1,10-decanediol, 100mL of tetrahydrofuran and 0.028g of dibutyltin dilaurate into a round-bottomed flask equipped with a magnet, mix well and set the temperature to Warm to 50°C. Dissolve 2.22 g of isophorone diisocyanate in 50 mL of tetrahydrofuran, drop it into a round bottom flask through a constant pressure dropping funnel over 3 hours, and react at 50°C for 10 hours after the addition is complete until the isocyanate groups in the system are completely reacted. Weigh 3.10g of isocyanatoethyl methacrylate and 0.03g of p-hydroxyanisole into the reaction system, continue to react at 50°C for 24 hours until the isocyanate group in the system is completely reacted, and after cooling to room temperature, the reaction The product was purified to obtain AF 8 CH 3 .

Embodiment 3

[0059] A low surface energy hydrophobic dental resin, wherein the mass percentage of each component is: 59.16% AF 4 CH 3 , 29.58% hexafluorobutyl methacrylate, 9.86% triethylene glycol dimethacrylate, 0.7% camphorquinone and 0.7% dimethylaminoethyl methacrylate. Weigh each component in parts by mass and put it in a dark place to mix evenly. 2 Example 3 was obtained by illuminating for 40 seconds under blue light.

[0060] Surface energy, contact angle and polymerization shrinkage of the resin obtained in table 1 embodiment 3 and comparative example 1 photocuring

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com