Iron-copper bimetallic sulfide microsphere, preparation method thereof and application of iron-copper bimetallic sulfide microsphere in water treatment

A bimetallic and sulfide technology, applied in special compound water treatment, oxidized water/sewage treatment, neutralized water/sewage treatment, etc., can solve the problem of weakened catalytic effect of metal ion pollutants, increased cost, increased secondary process, etc. problem, to achieve high catalytic activation persulfate efficiency, reduce consumption, and wide application space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0037] Preparation Example 1 The preparation of iron-copper bimetallic sulfide microspheres

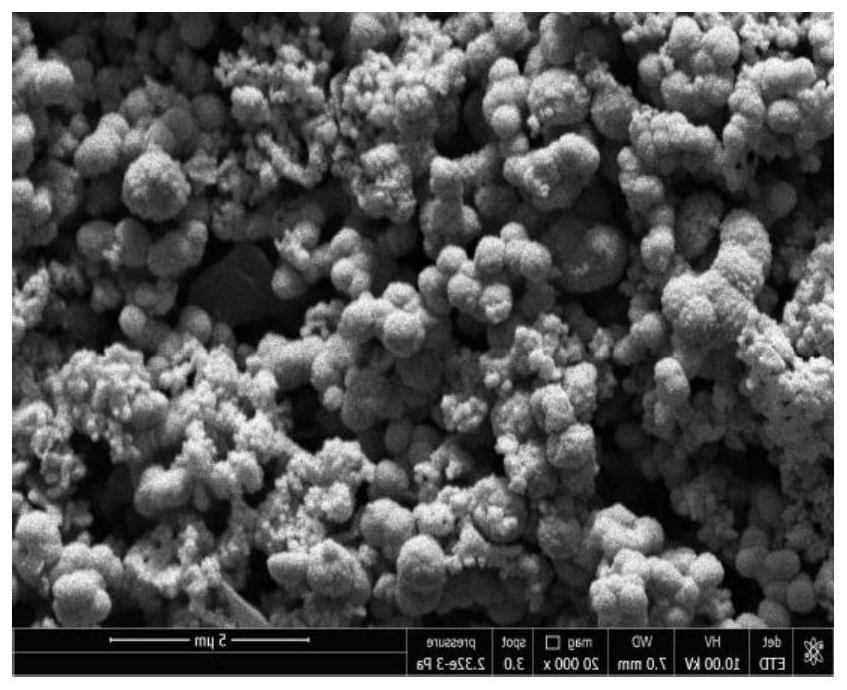

[0038] Weigh a certain amount of copper sulfate and ferrous sulfate and add them to 50mL ethylene glycol solution, stir well at room temperature to dissolve, then add 0.1522g thiourea and continue stirring for 1h to form a yellow precursor solution. The prepared precursor solution was transferred to a 100 mL high-pressure reaction axe, and reacted at 200 °C for 12 h to obtain a black solid powder. The resulting black powder was washed three times with deionized water and absolute ethanol, and dried overnight at 80°C for later use. In order to optimize the ratio of iron to copper, bimetallic sulfides with 1:1, 1:2, 1:3, 1:4 and 2:1 mass ratio of copper to iron were prepared respectively. Most preferably, the mass ratio of copper, iron and thiourea of the best catalyst is 1: 3: 2, and the microscopic appearance of the iron-copper bimetallic sulfide microspheres is as follows: figure...

Embodiment 1

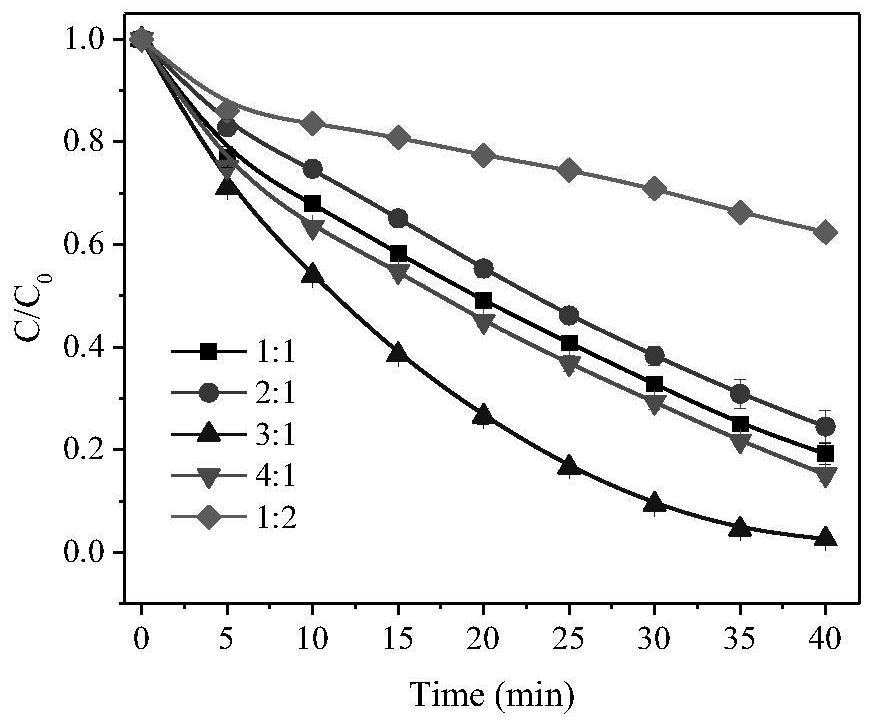

[0039] Embodiment 1 uses iron-copper bimetallic sulfide microspheres with different iron-copper mass ratios for water treatment

[0040] First, add 100 mL of sulfonamide antibiotics into the beaker at a concentration of 10 mg / L, and adjust the initial pH of the system to 7 with 0.1 mM sulfuric acid solution and 0.1 mM sodium hydroxide solution. Then add 20 mg of iron-copper bimetallic sulfide microspheres with different iron-copper mass ratios of 1:1, 2:1, 3:1, 4:1 and 4:1 to the reaction system, and fully stir to make them mixed. 81 mg of potassium peroxodisulfate was added, and the reaction was carried out at 25° C., and the initial concentration of potassium peroxodisulfate in the reaction system was 3 mM. Take samples at intervals, quench with methanol and do the degradation curve of antibiotics, the results are as follows figure 2 shown. The results show that different ratios of iron-copper bimetallic sulfides have different removal effects on pollutants. As the iron c...

Embodiment 2

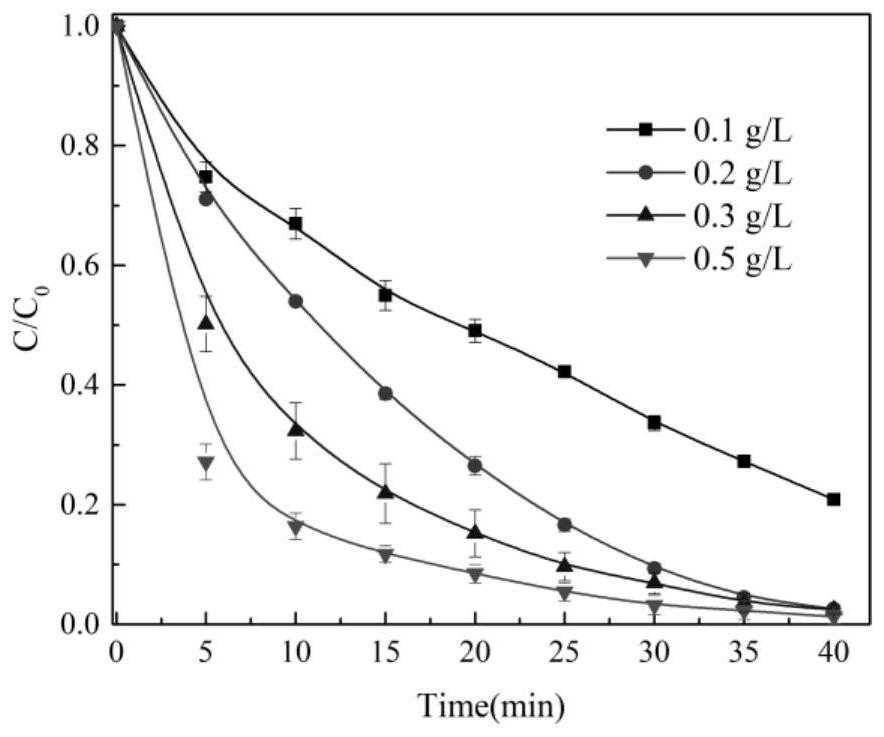

[0041] Embodiment 2 The influence of the dosage of iron-copper bimetallic sulfide microspheres on water treatment

[0042] First, add 100 mL of sulfonamide antibiotics into the beaker at a concentration of 10 mg / L, and adjust the initial pH of the system to 7 with 0.1 mM sulfuric acid solution and 0.1 mM sodium hydroxide solution. Then add the prepared iron-copper bimetallic sulfide microspheres (mass ratio of iron-copper: 3:1) to the reaction system, change the amount of addition to 10mg, 20mg, 30mg and 50mg, and stir thoroughly to mix them. 81 mg of potassium peroxodisulfate was added, and the reaction was carried out at 25° C., and the initial concentration of potassium peroxodisulfate in the reaction system was 3 mM. Take samples at intervals, quench with methanol and do the degradation curve of antibiotics, the results are as follows image 3 shown. The results show that with the increase of catalyst concentration, the removal effect of pollutants is enhanced, which is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com