Preparation method of electrostatic spinning functional nanofiber film for epidermis repair

A nanofiber membrane and electrospinning technology, applied in the field of medical cosmetology, can solve the problems of fiber geometry control restrictions, unfavorable fiber stacking, complex and time-consuming process, etc., and achieve the effect of improving mechanical properties and improving hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below with reference to the accompanying drawings.

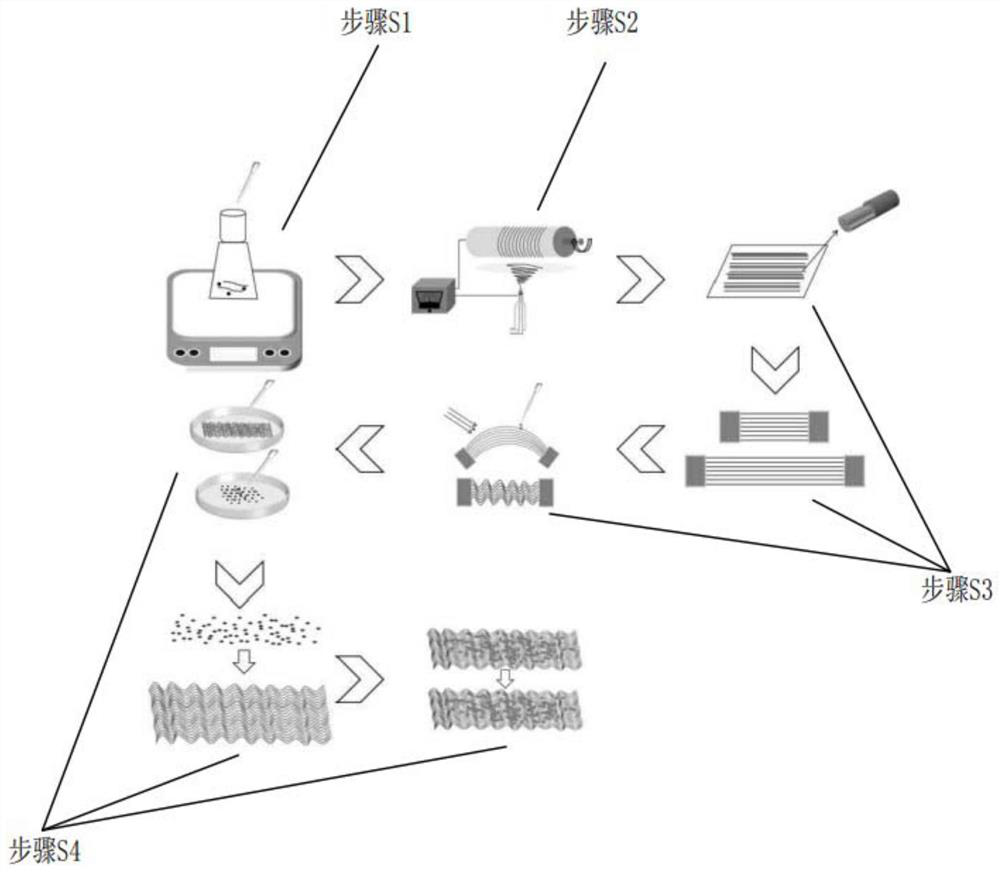

[0026] The preparation method of electrospinning functional nanofiber film for skin repair, reference attached figure 1 The method includes the following steps:

[0027] Step S1: Preparation of polylactic acid adipate spinning fluid and polyethylene glycol spinning liquid: mixed dichloromethane and dimethylformamide in a volume ratio of 7: 3, then add polylactate induced In the solution, the concentration of polylactic acid caprolactone spun is obtained; polyethylene glycols having a mass percentage of 50% are dissolved in dimethylformamide, formulated into polyethylene glycol spinning fluid. ;

[0028] Step S2: A polylactic acid adipate spinning liquid and polyethylene glycol spinning liquid into the coaxial nozzle of the electrostatic spinning machine, turn the coaxial nozzle to the positive electrode of the high voltage power supply, and set fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com