Lightweight heat-insulating semi-flexible anti-cracking pavement and preparation method thereof

A semi-flexible pavement, light-weight thermal insulation technology, applied in the direction of on-site coagulation pavement, roads, roads, etc. Problems such as the stable reduction of the volume of pavement materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

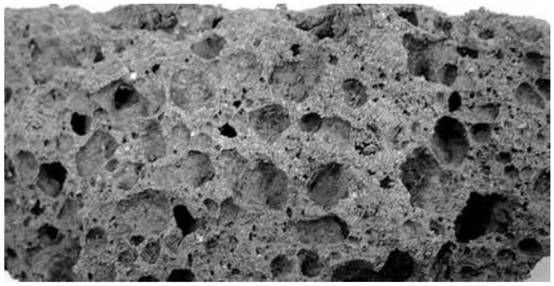

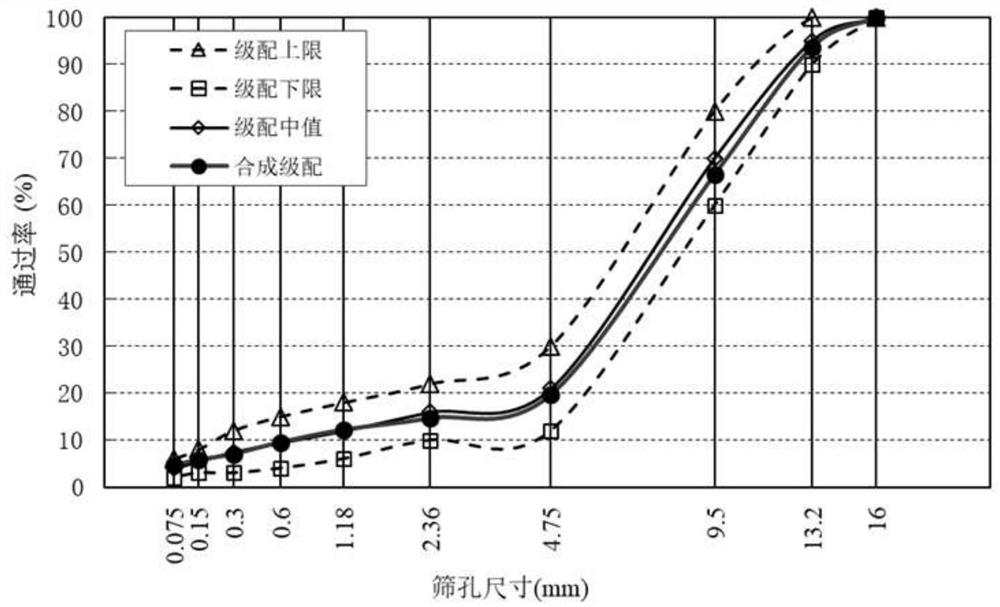

[0052] A light heat-insulating semi-flexible crack-resistant pavement, which includes large-void asphalt concrete and foamed cement mortar filled therein, with a slurry rate of more than 80%. The preparation method includes the following steps:

[0053] 1) Weighing of raw materials; the mass percentage of each solid particle in large-void asphalt concrete is: 36% of basalt aggregate with a particle size of 9.5-16mm, 49% of basalt aggregate with a particle size of 4.75-9.5mm, and 2.36-4.75mm 2% basalt aggregate, 9% basalt aggregate with a particle size of 0-2.36mm, 4% limestone mineral powder filler, high-viscosity modified asphalt with an oil-stone ratio of 3.3; in the foamed cement mortar, 250 parts of cement, fly ash 500 parts, 220 parts of lime, 30 parts of gypsum, 1 part of aluminum powder paste, 5 parts of anhydrous sodium sulfate, 5 parts of sodium polyacrylate, 40 parts of carboxylated styrene-butadiene emulsion, and the ratio of water to material used is 0.65;

[0054]...

Embodiment 2

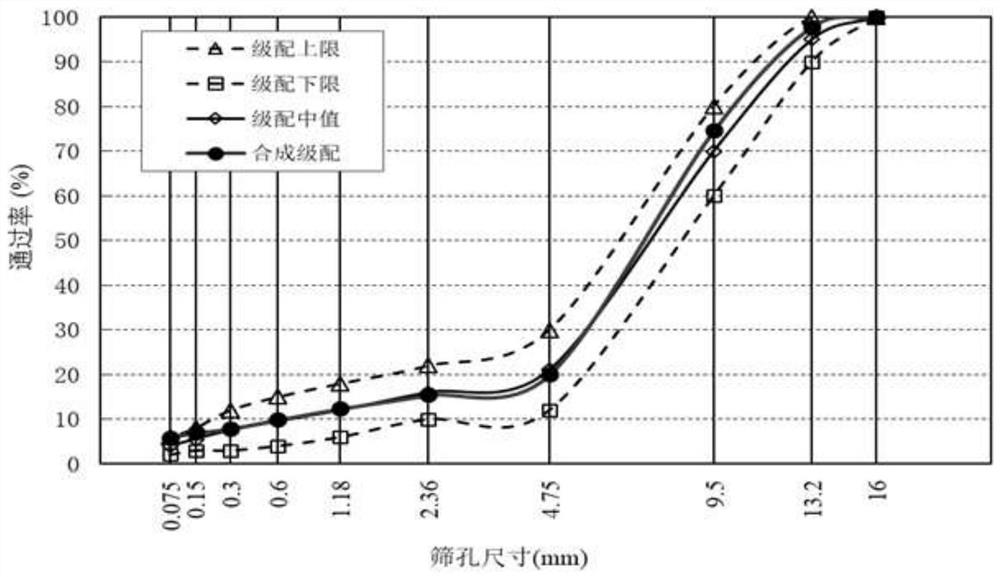

[0061] A light-weight heat-insulating semi-flexible anti-crack pavement, which includes large-void asphalt concrete and foamed cement mortar filled therein, with a grouting rate of more than 80%. The preparation method includes the following steps:

[0062] 1) Weighing of raw materials; the mass percentage of each solid aggregate in large-void asphalt concrete is: 35% of steel slag aggregate with particle size of 9.5-16mm, 48% of steel slag aggregate with particle size of 4.75-9.5mm, and 2.36-4.75mm of particle size 3% of steel slag aggregate, 10% of steel slag aggregate with a particle size of 0-2.36mm, 4% of limestone mineral powder filler, and 3.5 oil-stone ratio for high-viscosity modified asphalt; in foamed cement mortar, 250 parts of cement, fly ash 500 parts, 220 parts of lime, 30 parts of gypsum, 1 part of aluminum powder paste, 5 parts of anhydrous sodium sulfate, 5 parts of sodium polyacrylate, 40 parts of carboxylated styrene-butadiene emulsion, and the ratio of wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com