Composite material with nickel-based super-hydrophobic nano CeO2 composite coating and preparation method of composite material

A composite coating and composite material technology, applied in coatings, electrolytic coatings, etc., can solve problems such as corrosion and cracking of metal materials, ordinary Ni-P coating cannot meet the requirements of industrial production and use of metal pipes, and ordinary Ni-P coating pitting corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

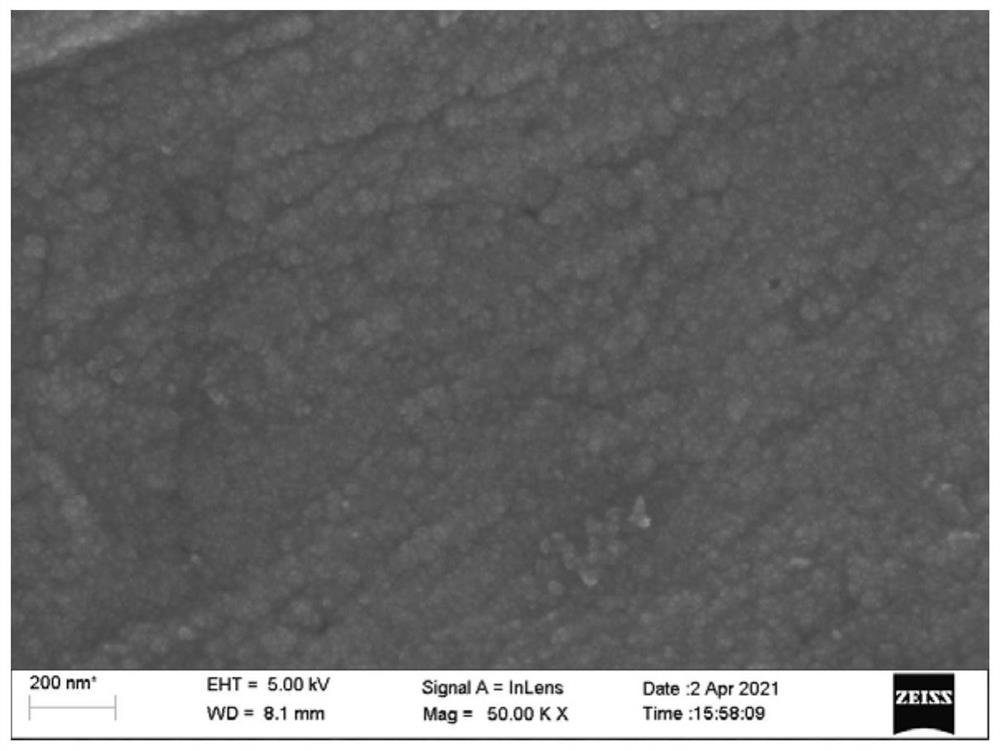

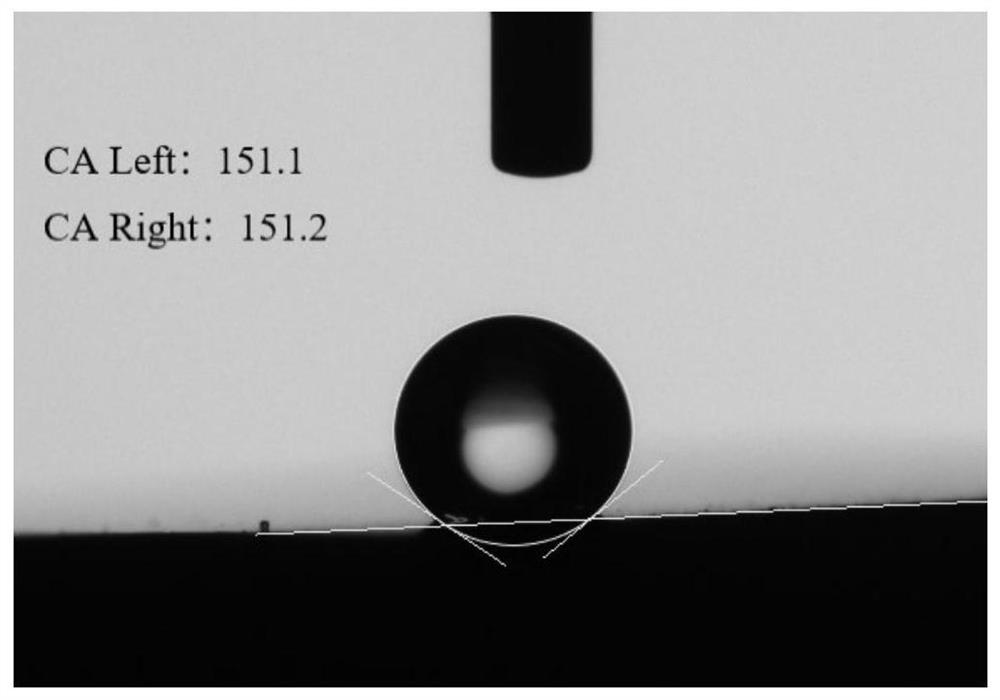

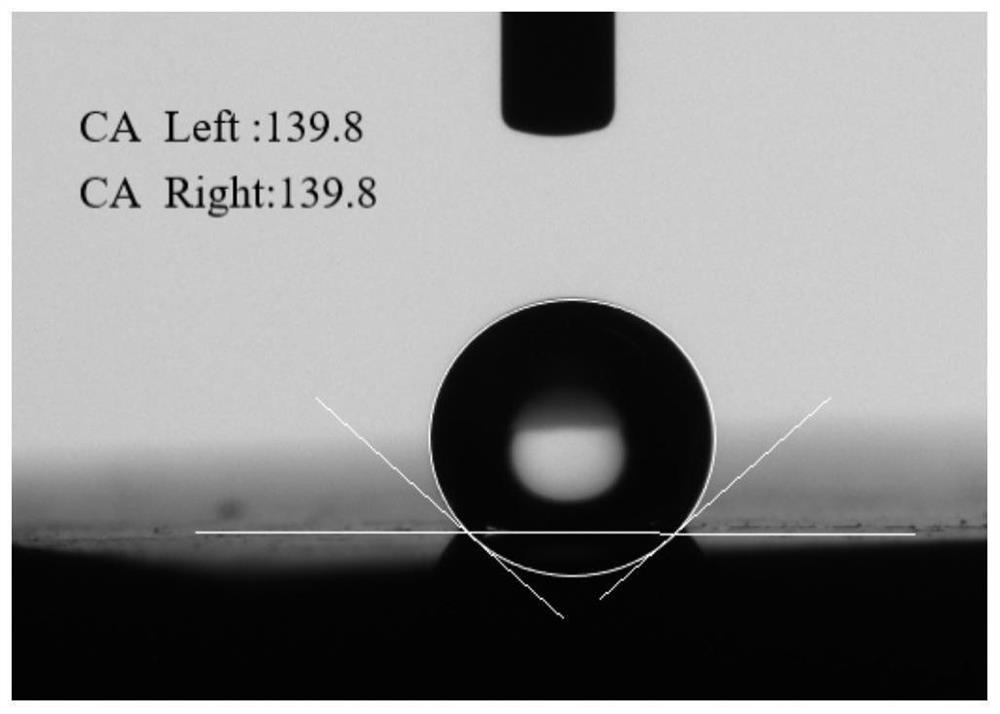

[0028] The invention has nickel-based super-hydrophobic nano-CeO 2 The preparation method of the composite material of composite coating comprises the following steps:

[0029] (1) Substrate pretreatment: mechanical grinding and polishing of the workpiece → ultrasonic degreasing of lye → water washing → activation of sulfuric acid → water washing, wherein the composition of the degreasing lye is: 5-15g / L NaOH, 20-35g / L NaOH 2 CO 3 , 10~25g / L Na 3 PO 4 12H 2 O, ultrasonic degreasing time is 30-50min, temperature is 20-25°C; use 0.3-0.7mol / L sulfuric acid for sulfuric acid activation.

[0030] (2) Ni-P-CeO 2 Plating solution configuration: Nickel sulfate (NiSO 4 ·6H 2 O); nickel chloride (NiCl 2 ·6H 2 O); boric acid (H 3 BO 3 ); phosphorous acid (H 3 PO 3 ); Citric acid; Thiourea; Sodium dodecylbenzenesulfonate (SDBS); Ammonium chloride (NH 4 Cl) obtain Ni-P alloy plating solution after fully stirring and dissolving in a beaker; Nano CeO 2 After the particles are ...

Embodiment 1

[0036] This embodiment has nickel-based superhydrophobic nano-CeO 2 The preparation method of the composite material of composite coating comprises the following steps:

[0037] (1) Preparation of 1L Ni-P-CeO 2 Plating solution: weigh 2g nano-CeO with an electronic balance 2 ;100g NiSO 4 ·6H 2 O; 20gNiCl 2 ·6H 2 O; 15g H 3 PO 3 ; 20g H 3 BO 3 ; 60g citric acid; 0.05g thiourea; 0.05g sodium dodecylbenzene sulfonate; 20g ammonium chloride was slowly added to a beaker with an appropriate amount of deionized water, stirred evenly and then added deionized water to settle to 1L to obtain Ni -P-CeO 2 Alloy plating solution, stand for use.

[0038] (2) Grind and polish the X100 steel base with a size of 8mm×8mm×3mm with #120 to #1500 water sandpaper to remove the oxide layer on the surface of the X100 steel base, and then clean the polished X100 base steel with deionized water Clean and blow dry. The reuse composition is 10g / L NaOH, 30g / L NaOH 2 CO 3 , 20g / L Na 3 PO 4...

Embodiment 2

[0043] This embodiment has nickel-based superhydrophobic nano-CeO 2 The preparation method of the composite material of composite coating comprises the following steps:

[0044] (1) Preparation of 1L Ni-P-CeO 2 Plating solution: weigh 3g nano-CeO with an electronic balance 2 ;110g NiSO 4 ·6H 2 O; 25gNiCl 2 ·6H 2 O; 20g H 3 PO 3 ;30g H 3 BO 3 ; 70g citric acid; 0.07g thiourea; 0.07g sodium dodecylbenzenesulfonate; 25g ammonium chloride was slowly added to a beaker with an appropriate amount of deionized water, stirred evenly, and then added deionized water to settle to 1L to obtain Ni -P-CeO 2 Alloy plating solution, stand for use.

[0045] (2) Grind and polish the X100 steel base with a size of 8mm×8mm×3mm with #120 to #1500 water sandpaper to remove the oxide layer on the surface of the X100 steel base, and then clean the polished X100 base steel with deionized water Clean and blow dry. The reuse composition is 10g / L NaOH, 30g / L NaOH 2 CO 3 , 20g / L Na 3 PO 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com