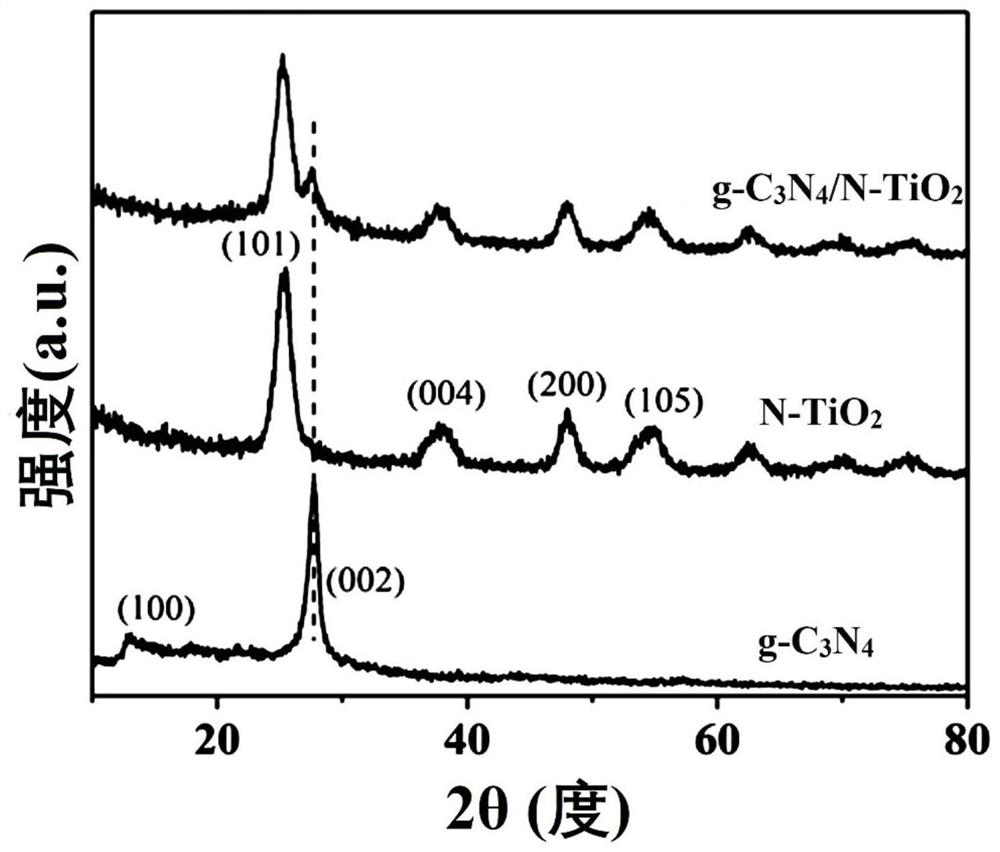

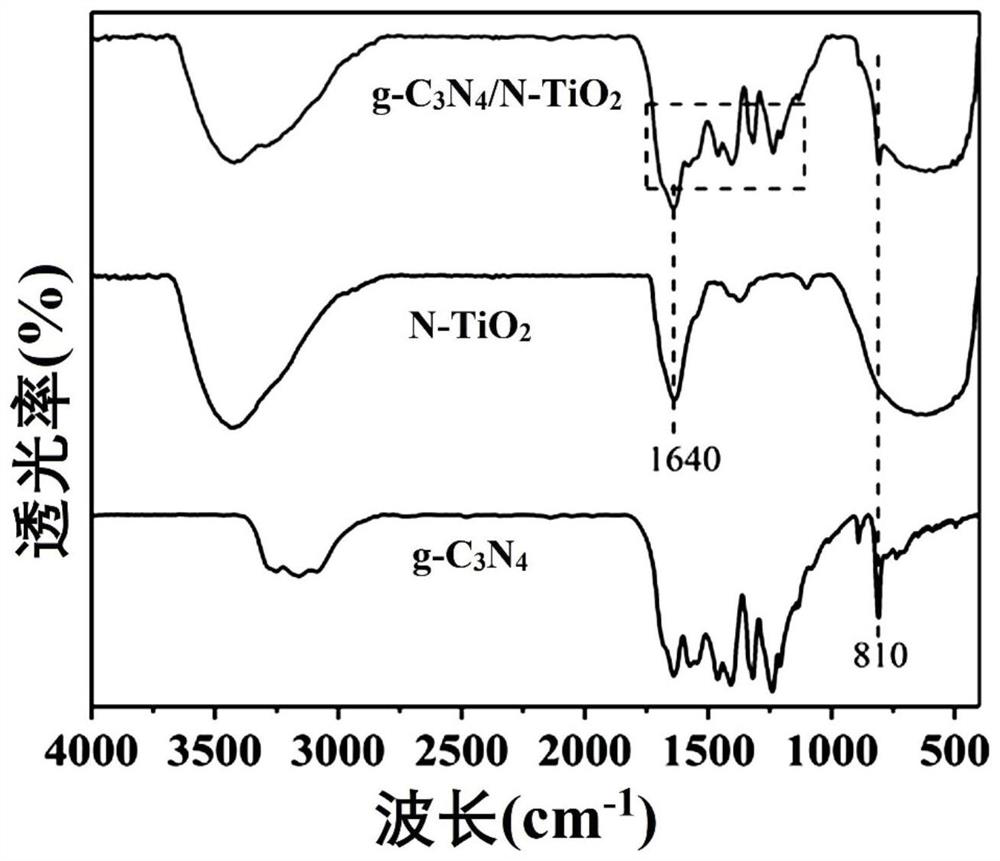

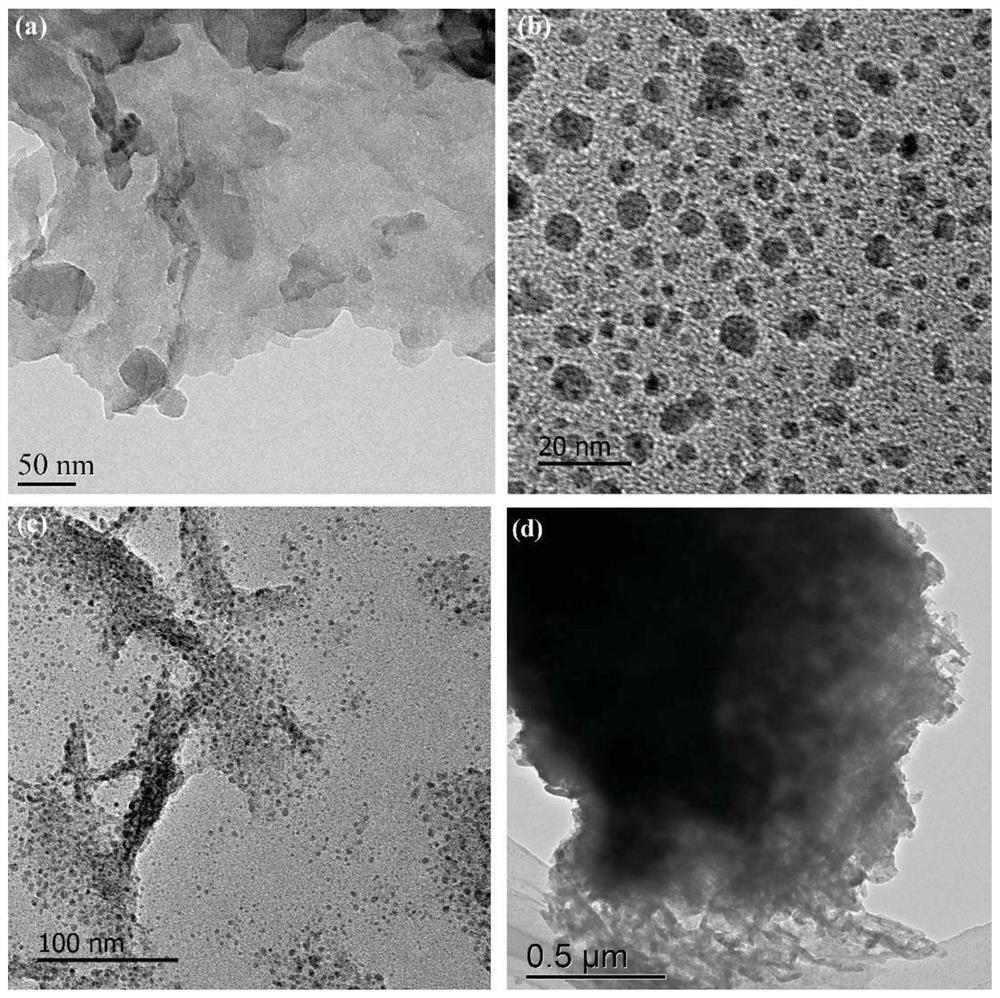

Graphite-phase carbon nitride composite photocatalyst and preparation method thereof

A technology of graphite phase carbon nitride and composite light, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of photocatalytic activity of composite materials that need to be improved, unfavorable effective separation of electron-hole pairs, Insufficient contact and other problems to achieve the effect of tight combination, improved quantum efficiency, and improved separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Put 40g of melamine into a crucible with a cover, raise the temperature to 550°C at 4°C / min in a muffle furnace, then heat-preserve and calcinate for 4h, and after cooling to room temperature, block graphite phase carbon nitride (g-C 3 N 4 ), ground into powder, put it into a crucible with a cover, heated up to 550°C at 5°C / min in a muffle furnace, and then heat-preserved and calcined for 3h to obtain g-C 3 N 4 Nanosheets;

[0042] (2) Add 1g g-C 3 N 4 Mix the nanosheets with 60ml of absolute ethanol and 3ml of glacial acetic acid with a purity ≥ 99.5%, and form a uniform mixture A after magnetic stirring for 30 minutes; drop 2ml of butyl titanate into the mixture A, and form a uniform mixture B after magnetic stirring for 30 minutes; Drop 1ml of ammonia water containing 25% to 28% ammonia into mixture B, and stir magnetically for 60 minutes to form a uniform precursor; put the precursor in an oven at 100°C for 12 hours and then grind it to obtain a powder. Put ...

Embodiment 2

[0053] (1) Put 45g of melamine into a crucible with a cover, raise the temperature to 550°C at 4°C / min in a muffle furnace, then heat-preserve and calcinate for 4h, and after cooling to room temperature, block graphite phase carbon nitride (g-C 3 N 4 ), ground into powder, put it into a crucible with a cover, heated up to 550°C at 5°C / min in a muffle furnace, and then heat-preserved and calcined for 3h to obtain g-C 3 N 4 Nanosheets;

[0054] (2) Add 2g g-C 3 N 4 Mix the nanosheets with 80ml of absolute ethanol and 3ml of glacial acetic acid with a purity ≥ 99.5%, and form a uniform mixture A after magnetic stirring for 20 minutes; drop 3ml of butyl titanate into the mixture A, and form a uniform mixture B after magnetic stirring for 30 minutes; Drop 1.8ml of ammonia water containing 25% to 28% ammonia into mixture B, and stir magnetically for 60 minutes to form a uniform precursor; dry the precursor in an oven at 120°C for 16 hours and grind to obtain a powder. In a cove...

Embodiment 3

[0057] (1) Put 50g of melamine into a crucible with a cover, raise the temperature to 550°C at 4°C / min in a muffle furnace, then heat-preserve and calcinate for 4h, and after cooling to room temperature, block graphite phase carbon nitride (g-C 3 N 4 ), ground into powder, put it into a crucible with a cover, heated up to 550°C at 5°C / min in a muffle furnace, and then heat-preserved and calcined for 3h to obtain g-C 3 N 4 Nanosheets;

[0058] (2) Add 1g g-C 3 N 4 Mix the nanosheets with 60ml of absolute ethanol and 2ml of glacial acetic acid with a purity ≥ 99.5%, and form a uniform mixture A after magnetic stirring for 20 minutes; drop 3ml of butyl titanate into the mixture A, and form a uniform mixture B after magnetic stirring for 20 minutes; Drop 1.2ml of ammonia water containing 25% to 28% ammonia into mixture B, and stir magnetically for 40 minutes to form a uniform precursor; dry the precursor in an oven at 120°C for 16 hours and grind to obtain a powder. Put the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com