Samarium-doped sodium bismuth titanate-bismuth strontium titanate ceramic material with high energy storage density and preparation method thereof

A high energy storage density, sodium bismuth titanate technology, applied in the field of ceramic capacitor material processing, can solve the problem of insufficient energy storage density, and achieve the effect of less surface air gap, low preparation cost and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

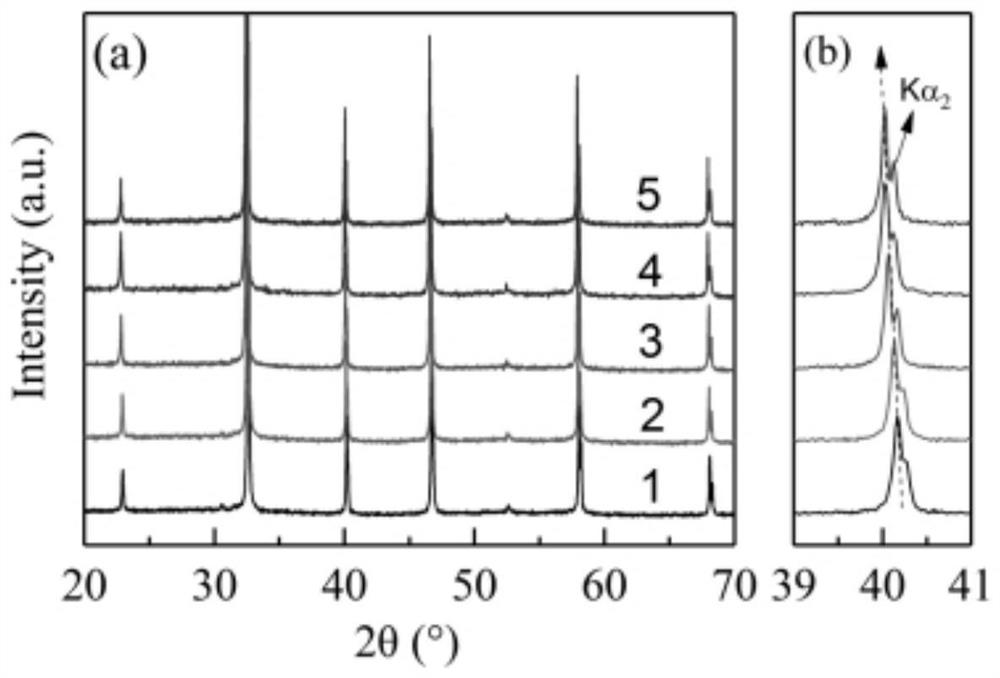

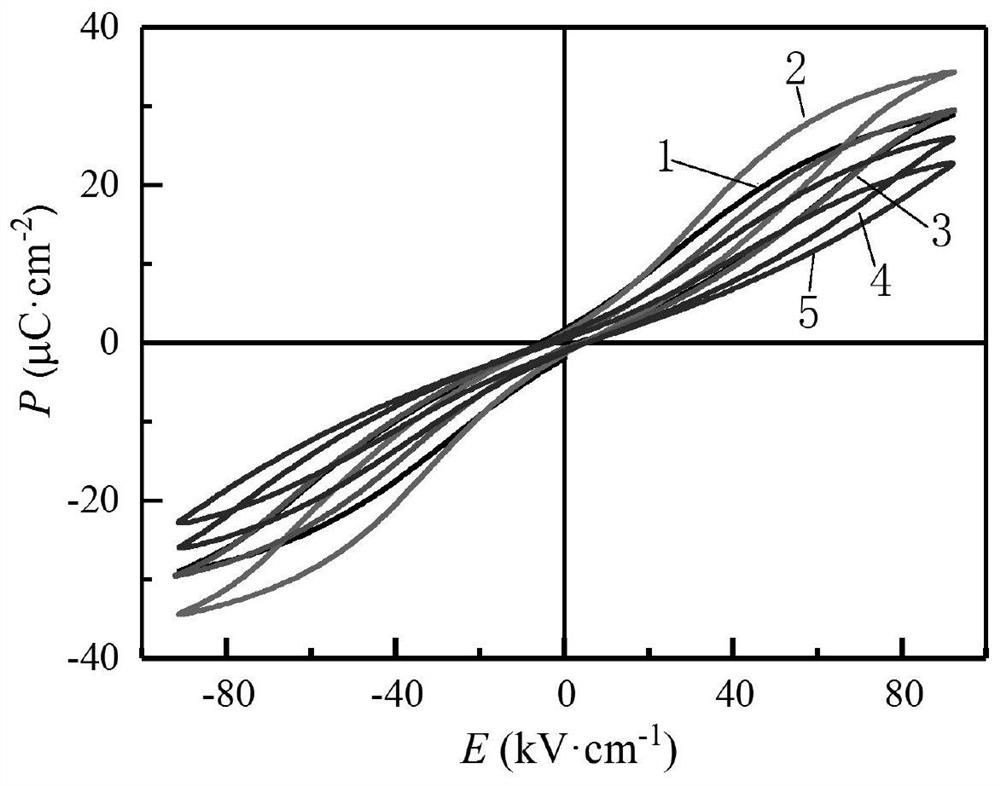

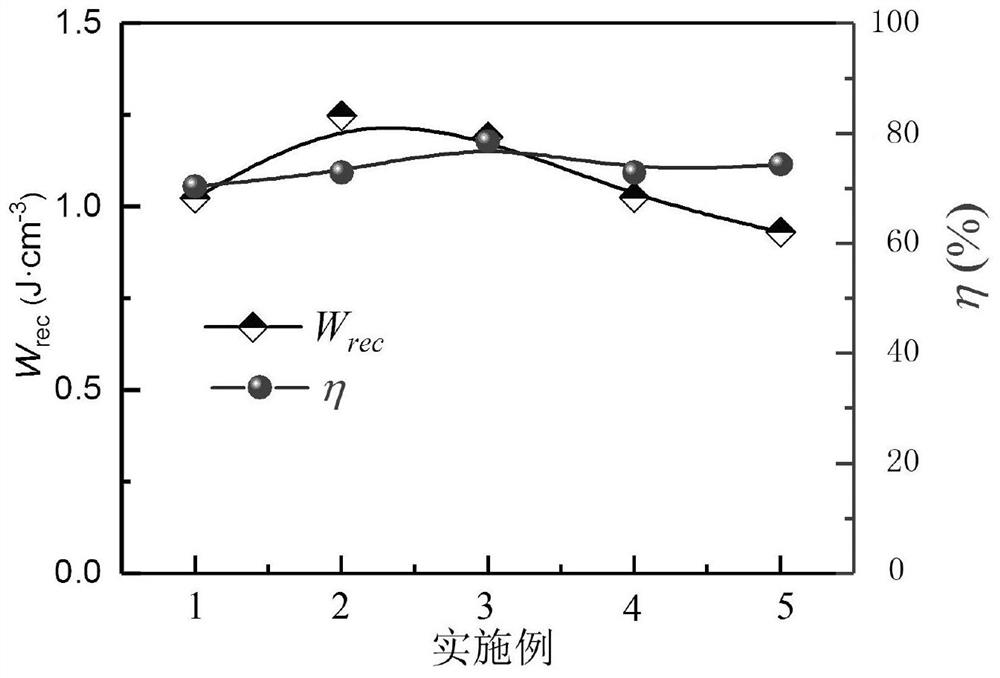

Embodiment 1

[0031] A highly accumulated density of bismuth sodium titanate-titanate ceramic material, the bismuth titanate-titanate-titanate ceramic material according to ((Bi 0.5 NA 0.5 ) 0.7 (SR 0.7 BI 0.2 ) 0.3 ) 1-x SM x TIO 3 The chemical metering ratio weighing powder (where x = 0), ie (Bi 0.5 NA 0.5 ) 0.7 (SR 0.7 BI 0.2 ) 0.3 TIO 3 , Prepare it as follows:

[0032] (1) Raw material preparation: Purity (> 98%) TIO 2 , BI 2 O 3 NA 2 CO 3 , SRCO 3 SM 2 O 3 Place 3 hours to remove moisture in an oven at 100 ° C, weigh 8.0671 g of titanium oxide, 9.6976 g of cerium oxide, 1.8736 g of sodium carbonate, 3.1315 g of sodium carbonate (0.0001 g of oxidation), mixed with mixed material ;

[0033] (2) Ball mill: The mixture of the above steps (1), anhydrous ethanol, and zirconia grinding balls are filled with a ratio of 3: 1: 1 for 12 hours, and it is baked;

[0034] (3) Calcination ball milling: The slurry is placed in a 100 ° C oven, pressed into a blank after sizing, and lids the alumina crucib...

Embodiment 2

[0043] A highly accumulated density of bismuth sodium titanate-titanate ceramic material, the bismuth titanate-titanate-titanate ceramic material according to ((Bi 0.5 NA 0.5 ) 0.7 (SR 0.7 BI 0.2 ) 0.3 ) 1-x SM x TIO 3 Chemical metrics ratio weighing powder (where x = 0.005), is ((Bi) 0.5 NA 0.5 ) 0.7 (SR 0.7 BI 0.2 ) 0.3 ) 0.995 SM 0.005 TIO 3 , Prepare it as follows:

[0044] (1) Raw material preparation: Purity (> 98%) TIO 2 , BI 2 O 3 NA 2 CO 3 , SRCO 3 SM 2 O 3 Place 3 hours to remove moisture in an oven at 100 ° C, weigh 8.0672 g of titanium dioxide, 9.6983 g of cerium oxide, sodium carbonate 1.8649g, and oxide 0.0881 g (accuracy of 0.0001 g), mixed with mixed materials spare;

[0045] (2) Ball mill: The mixture of the above steps (1), anhydrous ethanol, and zirconia grinding balls are filled with a ratio of 3: 1: 1 for 12 hours, and it is baked;

[0046] (3) Calcination ball milling: The slurry is placed in a 100 ° C oven, pressed into a blank after sizing, and lids the alu...

Embodiment 3

[0056] A highly accumulated density of bismuth sodium titanate-titanate ceramic material, the bismuth titanate-titanate-titanate ceramic material according to ((Bi 0.5 NA 0.5 ) 0.7 (SR 0.7 BI 0.2 ) 0.3 ) 1-x SM x TIO 3 Chemical measuring ratio weighing powder (where x = 0.01), is ((Bi) 0.5 NA 0.5 ) 0.7 (SR 0.7 BI 0.2 ) 0.3 ) 0.99 SM 0.01 TIO 3 , Prepare it as follows:

[0057] (1) Raw material preparation: Purity (> 98%) TIO 2 , BI 2 O 3 NA 2 CO 3 , SRCO 3 SM 2 O 3 Place 3 hours to remove moisture in an oven at 100 ° C, weigh 8.0672 g of titanium dioxide, 9.6006 g of cerium oxide, 1.8548 g of sodium carbonate, 3.1002 g of sodium carbonate, 0.1761 g of oxidation, and mixed mixed materials spare;

[0058] (2) Ball mill: The mixture of the above steps (1), anhydrous ethanol, and zirconia grinding balls are filled with a ratio of 3: 1: 1 for 12 hours, and it is baked;

[0059] (3) Calcination ball milling: The slurry is placed in a 100 ° C oven, pressed into a blank after sizing, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Energy storage density | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

| Energy storage density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com