Vanadium oxide electrode material with nanorod structure, and preparation method and application thereof

A nano-rod-shaped, electrode material technology, applied in electrolytic inorganic material coating, hybrid capacitor electrode, hybrid/electric double layer capacitor manufacturing and other directions, can solve problems such as low energy density, achieve high area specific capacitance, increase specific surface area, prepare the effect of time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Cut the carbon cloth into a size of 1 cm × 2.5 cm, wash it with absolute ethanol, and then ultrasonicate it with deionized water for 5 minutes, and dry the cleaned carbon cloth in a vacuum drying oven at 60°C.

[0028] (2) In the three-electrode system, carbon cloth was used as the working electrode, carbon paper was used as the counter electrode, and a saturated calomel electrode was used as the reference electrode. 3 The electrode is activated by the constant potential method in the solution, the potential is 1.8V, and the reaction time is 3h. After activation, rinse with deionized water to remove excess electrolyte, then place it in a three-electrode system, and use cyclic voltammetry to restore the electrode conductivity in a 3M KCl solution at a potential window of -1.2 to 1V, and scan the number of cycles for 100 laps. The treated samples were soaked in deionized water to remove excess electrolyte, and then dried in a vacuum oven at 60°C for 8 hours.

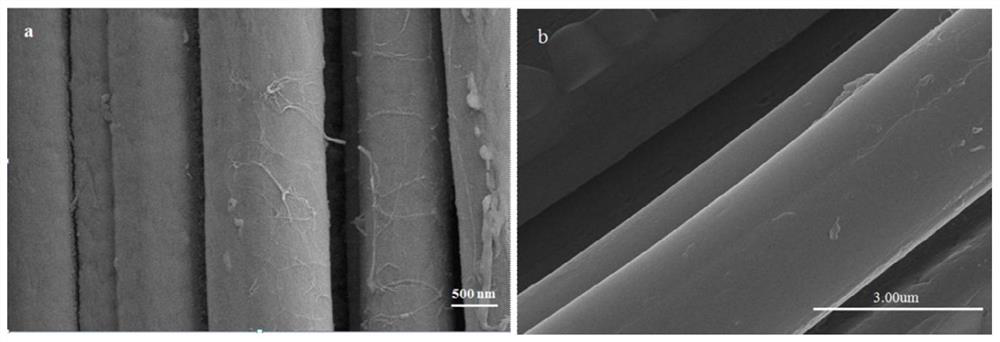

[0029...

Embodiment 2

[0031] 1) Cut the carbon cloth into a size of 1cm×2.5cm, wash it with absolute ethanol, and then ultrasonicate it with deionized water for 5 minutes, and dry the cleaned carbon cloth in a vacuum drying oven at 60°C.

[0032] 2) In the three-electrode system, carbon cloth was used as the working electrode, carbon paper was used as the counter electrode, and a saturated calomel electrode was used as the reference electrode. 4 :(NH 4 ) 2 Electrodeposition was carried out by cyclic voltammetry in a mixed solution with Ac ratio of 1:2. Potential window is -1.5 ~ 1.5V, scan 100 circles. The obtained samples were soaked in deionized water to remove excess electrolyte, and then dried in a vacuum oven at 60 °C for 8 h.

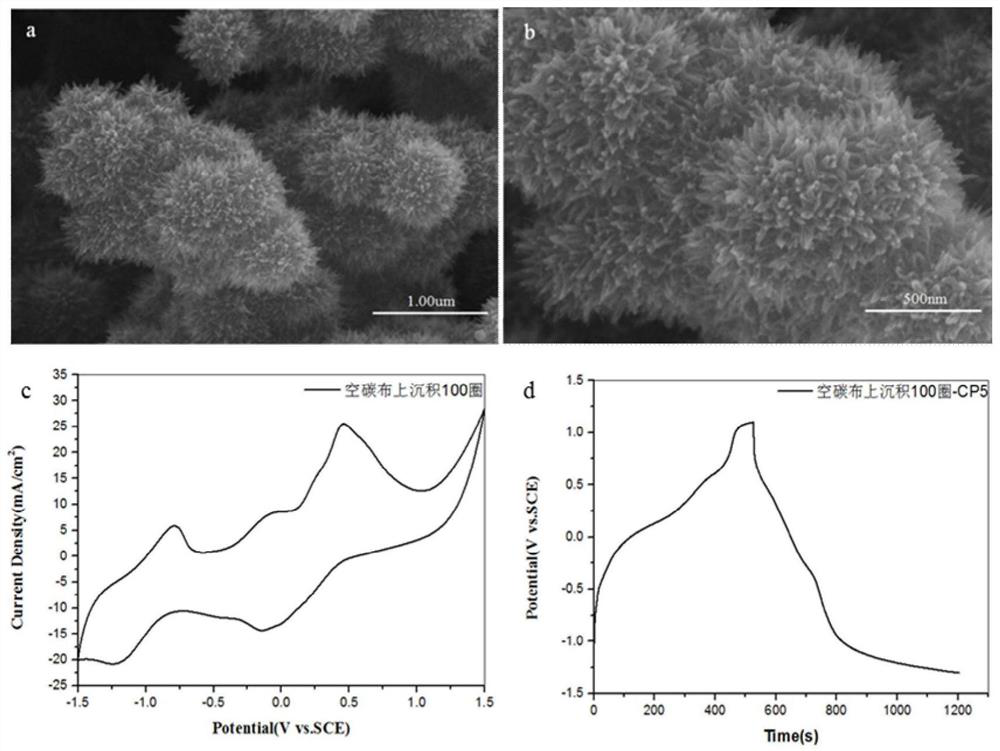

[0033] figure 2 Respectively step (2) in embodiment 2 obtains the low multiple of product figure 2 (a) and high multiple figure 2 (b) SEM, cyclic voltammetry curve (c) and galvanostatic charge-discharge curve (d) of deposited vanadium oxide. Depend on figur...

Embodiment 3

[0035] 1) Cut the carbon cloth into a size of 1cm×2.5cm, wash it with absolute ethanol, and then ultrasonicate it with deionized water for 5 minutes, and dry the cleaned carbon cloth in a vacuum drying oven at 60°C.

[0036] (2) In the three-electrode system, carbon cloth was used as the working electrode, carbon paper was used as the counter electrode, and a saturated calomel electrode was used as the reference electrode. 3 The electrode is activated by the constant potential method in the solution, the potential is 1.8V, and the reaction time is 3h. After activation, rinse with deionized water to remove excess electrolyte, then place it in a three-electrode system, and use cyclic voltammetry to restore the electrode conductivity in a 3M KCl solution at a potential window of -1.2 to 1V, and scan the number of cycles for 100 laps. The treated samples were soaked in deionized water to remove excess electrolyte, and then dried in a vacuum oven at 60°C for 8 hours.

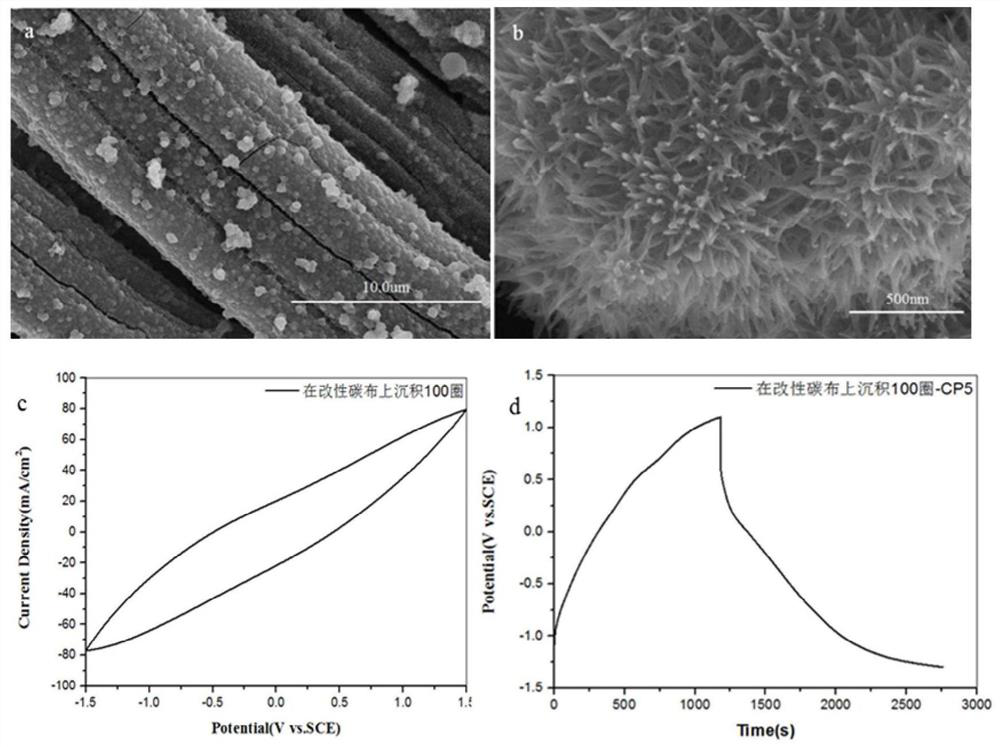

[0037] 3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com