Application of clostridium autoethanogenum protein in crustacean feed

A crustacean and Clostridium ethanol technology, applied in the field of feed, can solve the problems of high dissolution rate, reduced feed stability, inability to be self-sufficient, etc., to improve water stability, reduce feed dissolution rate, and reduce feed cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

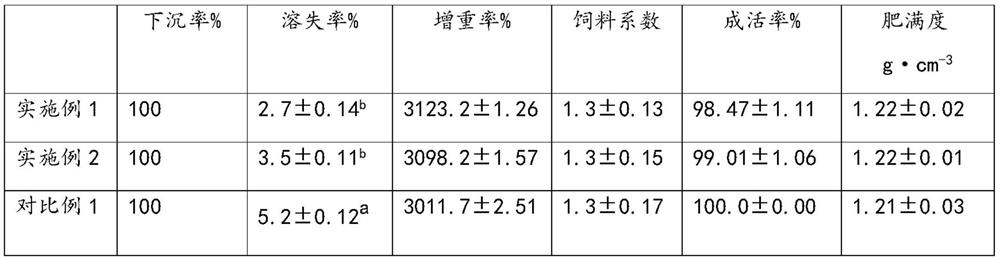

Embodiment 1

[0029] (1) The preparation method of ethanol clostridium protein comprises:

[0030] Clostridium autoethanogenum is placed in a gas with a CO mass fraction of 35-80% for liquid fermentation and culture to obtain a bacterial cell-containing fermentation liquid, and the bacterial cells in the bacterial cell-containing fermentation liquid are centrifuged and dried , The drying temperature for obtaining Clostridium ethanol protein is 150-200°C.

[0031] (2) According to parts by weight, the formula of Chinese prawn feed added with novel microbial protein source (Clostridium ethanol) is as follows: 20 parts of imported fish meal, 27 parts of peeled soybean meal, 4 parts of Clostridium ethanol protein, 12 parts of peanut bran, wheat flour 23.80 parts, 3 parts of whole shrimp powder, 3 parts of brewer's yeast, 3.4 parts of fat, 1.5 parts of calcium dihydrogen phosphate, 2.3 parts of premix additive.

[0032] The preparation method of Chinese prawn feed is as follows: mix imported fi...

Embodiment 2

[0035] (1) The preparation method of ethanol clostridium protein comprises:

[0036] Clostridium autoethanogenum is placed in a gas with a CO mass fraction of (35-80)% for liquid fermentation culture to obtain a fermentation broth containing bacteria;

[0037] centrifuging and drying the thalline in the thalline-containing fermentation broth to obtain the clostridium ethanol protein, wherein the drying temperature is 150-200°C.

[0038] (2) According to parts by weight, the feed formula of Chinese prawns added with novel microbial protein source (clostridium ethanol protein) is as follows: 23 parts of imported fish meal, 27 parts of peeled soybean meal, 1 part of clostridium ethanol protein, 12 parts of peanut bran, wheat flour 23.8 parts, 3 parts of whole shrimp powder, 3 parts of brewer's yeast, 3.4 parts of oil, 1.5 parts of calcium dihydrogen phosphate, 2.3 parts of premix additive.

[0039] The preparation method of Chinese prawn feed is as follows: mix imported fish mea...

Embodiment 3

[0042] (1) The preparation method of ethanol clostridium protein comprises:

[0043] placing Clostridium autoethanogenum in a gas with a CO mass fraction of 35-80%, and carrying out liquid fermentation culture to obtain a fermentation broth containing bacteria;

[0044] centrifuging and drying the bacteria in the bacteria-containing fermentation broth to obtain the clostridium ethanol protein, and the drying temperature is 150-200°C.

[0045] (2) According to parts by weight, the river crab feed formula that adds novel microbial protein source (clostridium ethanol protein) is as follows: 15 parts of imported fish meal, 10 parts of peeled soybean meal, 10 parts of rapeseed meal, 17 parts of clostridium ethanol protein, corn flour 16 parts, 18 parts of wheat bran, 5 parts of sweet potato flour, 4 parts of vegetable oil, 5 parts of additive premix.

[0046] The preparation method of river crab feed is as follows: mix imported fish meal, peeled soybean meal, rapeseed meal, corn f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com