Graphene modified water-based elastic coating and preparation method thereof

A graphene-modified, elastic coating technology, applied in the field of coatings, can solve the problems of single elastic brushed coating performance, poor stain resistance, no fire resistance, antibacterial and other problems, and achieves excellent stain resistance, good weather resistance, The effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

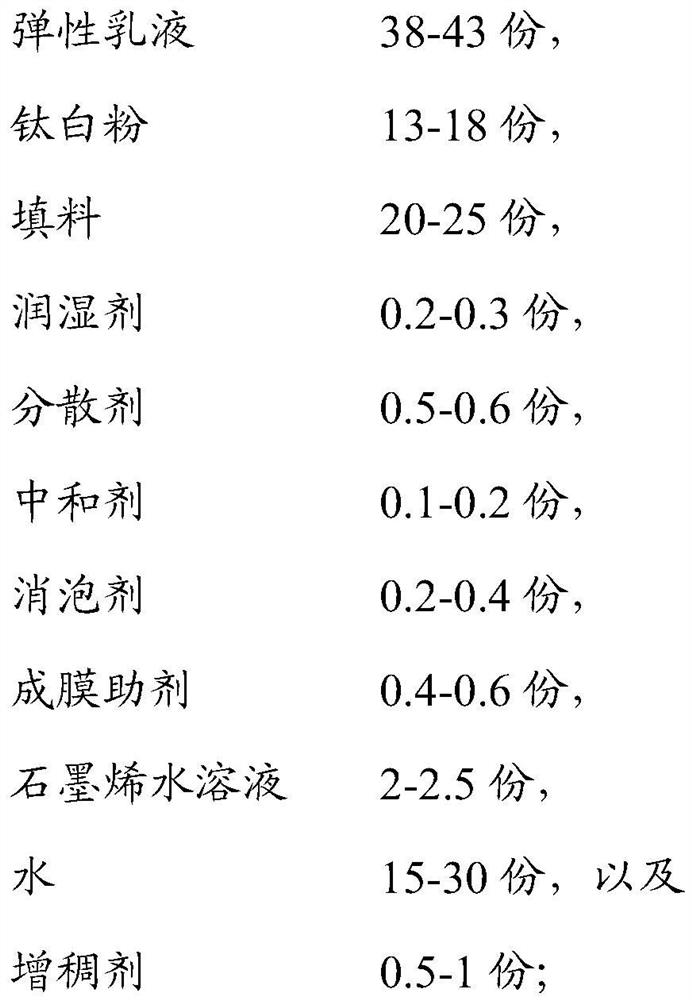

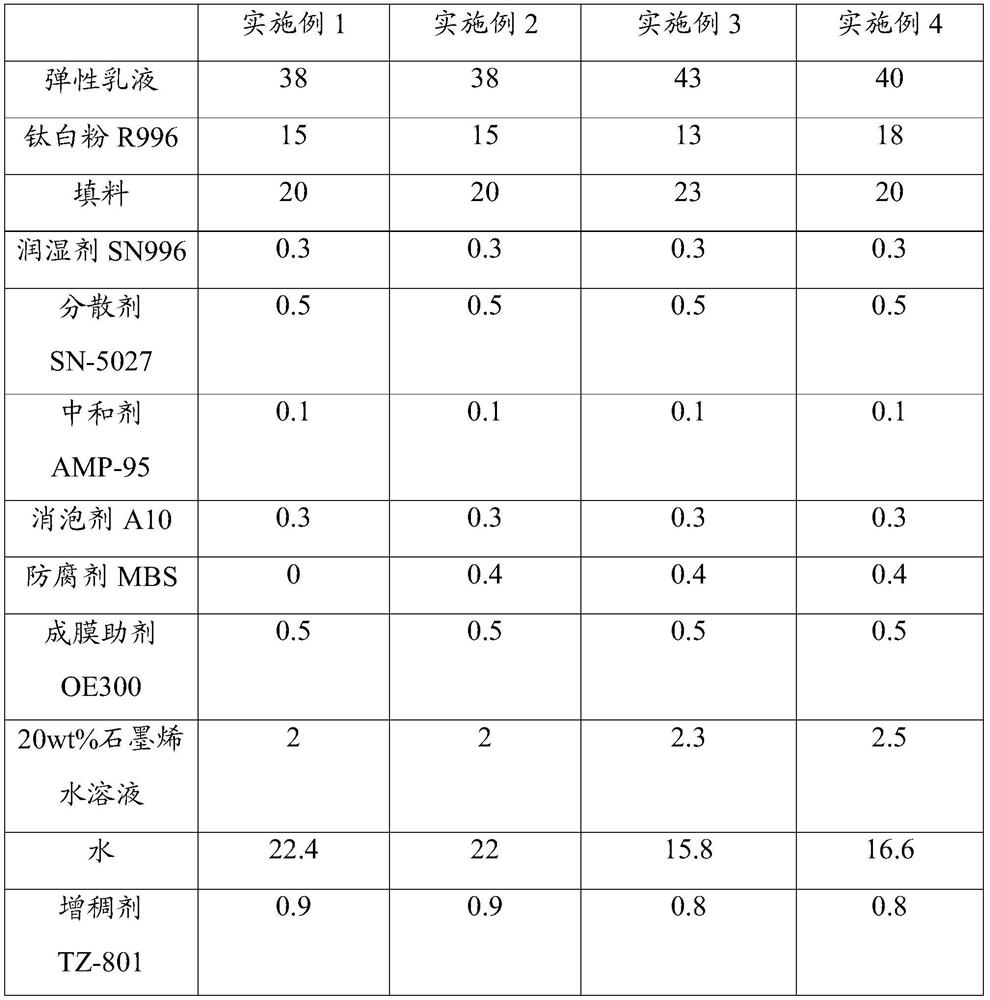

[0032] The formula is shown in Table 1.

[0033] Preparation:

[0034] Prepare graphene aqueous solution:

[0035] Select graphene nanosheets with a sheet diameter of 1-3 μm and a thickness of 1-5 nm, add 65wt% water as a dispersion medium in an ultrasonic device, and then add 5wt% isopropanol, 10wt% polyvinylpyrrolidone and 20wt% graphite olefin sheets, ultrasonically disperse for 3 hours, let stand for 24 hours, take the supernatant, put it in a centrifuge, centrifuge at 5000r / min for 30min, and take the supernatant;

[0036] Preparation of graphene-modified waterborne elastic coatings:

[0037] First add accurately weighed water into the pulling tank, and slowly add dispersant, wetting agent, film-forming agent, defoamer, neutralizer, and preservative in sequence at a low speed of 400r / min. Stir for 2 minutes, increase the rotation speed to 700r / min at medium speed, add titanium dioxide and filler in turn, increase the rotation speed to 1000r / min, disperse at high speed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com