Sulfonated phenolic resin modified polyacrylamide and preparation method thereof

A technology of sulfonated phenolic resin and polyacrylamide, which is applied in the fields of petroleum exploration and polymer polymerization, can solve the problems of general temperature and salt resistance and unfavorable application of polyacrylamide, and achieve the improvement and reduction of salt resistance and high temperature resistance. Influence, effect of excellent solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

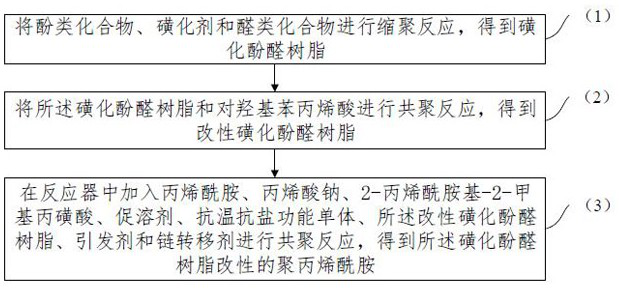

[0040] like figure 1 As shown, the invention provides a kind of preparation method of the polyacrylamide of sulfonated phenolic resin modification, and this preparation method comprises the steps:

[0041] (1) Polycondensation reaction of phenolic compound, sulfonating agent and aldehyde compound to obtain sulfonated phenolic resin;

[0042] (2) Copolymerizing the sulfonated phenolic resin and p-hydroxyphenylacrylic acid to obtain a modified sulfonated phenolic resin;

[0043] (3) Add acrylamide, sodium acrylate, 2-acrylamido-2-methylpropanesulfonic acid, solubilizer, temperature-resistant and salt-resistant functional monomer, the modified sulfonated phenolic resin, and initiator into the reactor Copolymerize with a chain transfer agent to obtain the polyacrylamide modified by the sulfonated phenolic resin.

[0044] In the present invention, preferably, the molecular weight of the sulfonated phenolic resin obtained in the step (1) is 500-1000, and is an anionic water-solubl...

Embodiment 1

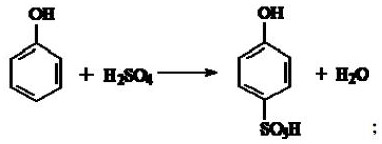

[0097] (1) Add 1 part of phenolic compound (phenol) to a three-neck flask equipped with a stirrer, reflux condenser and thermometer, and slowly add 1.2 parts of sulfonating agent (concentrated sulfuric acid with a mass fraction of 98%), at 100 °C Under the sulfonation reaction for 2h, the sulfonated phenol derivative is obtained; the sulfonation reaction is as follows:

[0098]

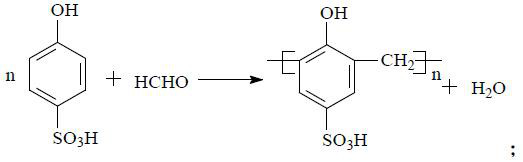

[0099] Then 2.2 parts of sulfonated phenol derivatives and 1 part of aldehyde compound (formaldehyde) were polycondensed at 100°C for 4 hours to obtain sulfonated phenolic resin; the polycondensation reaction is as follows:

[0100]

[0101] Wherein, n is 3-10;

[0102] (2) Add 0.5 parts of p-hydroxyphenyl acrylic acid dropwise to 1.5 parts of sulfonated phenolic resin obtained in step (1), and carry out a copolymerization reaction at 80°C for 1 hour to obtain a modified sulfonated phenolic resin after copolymerization; the copolymerization The response looks like this:

[0103]

[0104] Wh...

Embodiment 2

[0107] (1) Add 1 part of phenolic compound (2-methoxyphenol) to a three-necked flask equipped with a stirrer, reflux condenser and thermometer, and slowly add 0.8 parts of sulfonating agent (concentrated sulfuric acid with a mass fraction of 98% ), sulfonated at 80°C for 1.5h to obtain sulfonated phenol derivatives; then polycondensed 1.8 parts of sulfonated phenol derivatives and 1 part of aldehyde compound (formaldehyde) at 85°C for 3 hours to obtain sulfonated phenolic resin ;

[0108] (2) Add 0.5 parts of p-hydroxyphenyl acrylic acid dropwise to 1.5 parts of the sulfonated phenolic resin obtained in step (1), and conduct a copolymerization reaction at 100° C. for 1.5 hours to obtain a modified sulfonated phenolic resin after copolymerization;

[0109] (3) Mix 50 parts of acrylamide, 120 parts of sodium acrylate, 60 parts of 2-acrylamido-2-methylpropanesulfonic acid, 725 parts of deionized water, 15 parts of temperature-resistant and salt-resistant functional monomer (N-vin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com