Anti-ultraviolet polyamide fiber and preparation method thereof

A nylon fiber and anti-ultraviolet technology, which is applied in the fields of fiber chemical characteristics, rayon manufacturing, and single-component polyamide rayon, etc. It can solve the problem of decreased anti-ultraviolet performance, discounted anti-ultraviolet performance of nylon fiber, small nanoparticles, etc. problem, to achieve good UV shielding ability, long-lasting UV resistance and good hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

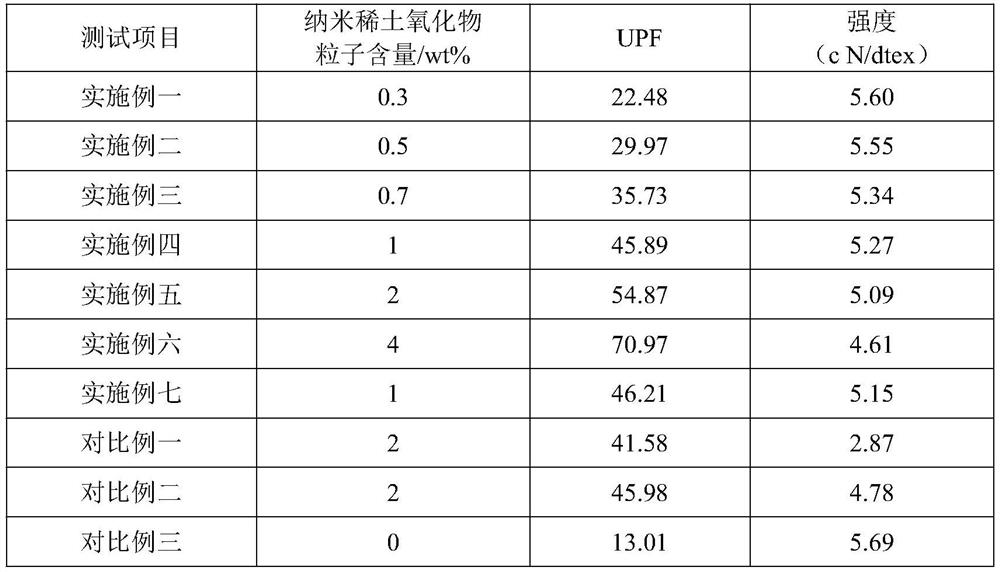

Examples

Embodiment 1

[0029] Embodiment 1: A kind of nylon fiber with anti-ultraviolet performance is prepared according to the following steps:

[0030] S1. Add 0.50 mol triisopropyl borate and 0.28 g sodium isopropoxide to a three-necked flask with a thermometer, a stirrer, and a reflux condenser, then raise the temperature to 100°C, and add 0.51 mol ethyl alcohol dropwise under constant stirring. Diol, heated and refluxed for 90 minutes, then added 0.51mol of 2-amino-3-hydroxypropionic acid, continued to reflux for 120 minutes at 150°C, and distilled off isopropanol under reduced pressure to obtain a chelating compound containing two functional groups. type borate coupling agent.

[0031] S2. Dry the nano-rare earth cerium oxide at 105°C for 2 hours, then add it and the borate coupling agent prepared above in a mass ratio of 100:1 to the high mixer that has been heated to 120°C for 30 minutes. Minutes, after cooling, borate-modified nano rare earth cerium oxide is obtained.

[0032] S3. Mix th...

Embodiment 2

[0033] Embodiment 2: A kind of nylon fiber with anti-ultraviolet performance is prepared according to the following steps:

[0034] S1. Add 0.50 mol triisopropyl borate and 0.28 g sodium isopropoxide to a three-necked flask with a thermometer, a stirrer, and a reflux condenser, then raise the temperature to 100°C, and add 0.52 mol ethyl alcohol dropwise under constant stirring. Diol, heated to reflux for 90 minutes, then added 0.52mol of 2-amino-3-hydroxypropionic acid, continued the reflux reaction at 150°C for 120 minutes, and distilled off isopropanol under reduced pressure to obtain a chelating compound containing bifunctional groups. type borate coupling agent.

[0035] S2. Dry the nano-rare earth cerium oxide at 105°C for 2 hours, and then add it and the borate coupling agent prepared above in a mass ratio of 100:1 to the high mixer that has been heated to 120°C for 45 Minutes, after cooling, borate-modified nano rare earth cerium oxide is obtained.

[0036] S3. Mix th...

Embodiment 3

[0037]Embodiment three: a kind of polyamide fiber with anti-ultraviolet performance is prepared according to the following steps:

[0038] S1. Add 0.50mol triisopropyl borate and 0.28g sodium ethylate to a three-neck flask with thermometer, stirrer, and reflux condenser, then raise the temperature to 100°C, and add 0.52mol ethylene glycol dropwise under constant stirring , heated to reflux for 90 minutes, then added 0.51mol of 2-amino-3-hydroxypropionic acid, continued the reflux reaction at 150°C for 120 minutes, and distilled off isopropanol under reduced pressure to obtain chelated boron with bifunctional groups Ester coupling agent.

[0039] S2. Dry the nano-rare earth cerium oxide at 105°C for 2 hours, and then add it and the borate coupling agent prepared above in a mass ratio of 100:1 to the high mixer that has been heated to 120°C for 45 Minutes, after cooling, borate-modified nano rare earth cerium oxide is obtained.

[0040] S3. Mix the modified nano-rare earth cer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com